Cloth edge curler

A technology of crimper and cloth strip, applied in the field of sewing machine accessories, can solve the problems of low efficiency, size error, time-consuming and laborious, etc., and achieve the effect of speeding up efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

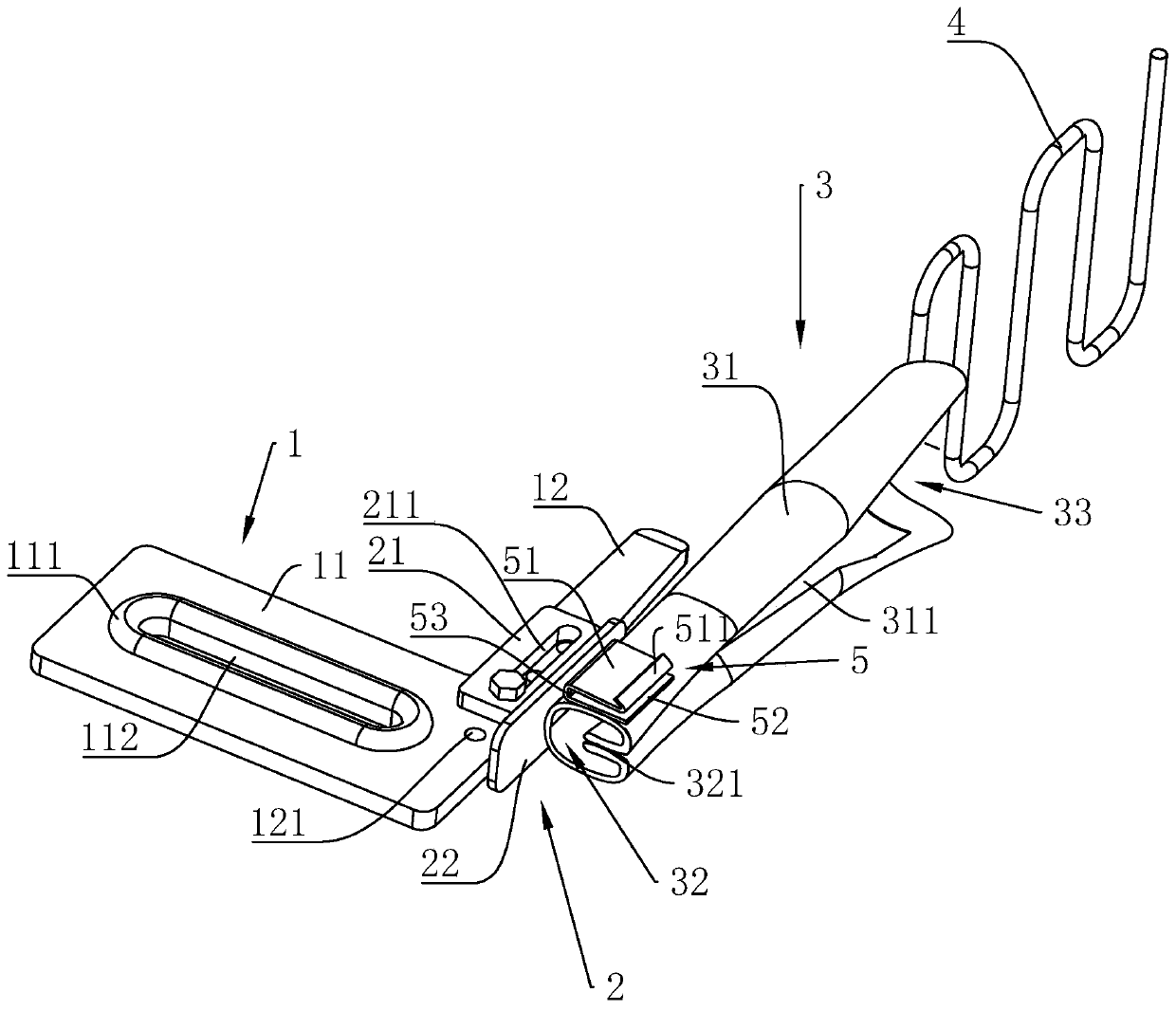

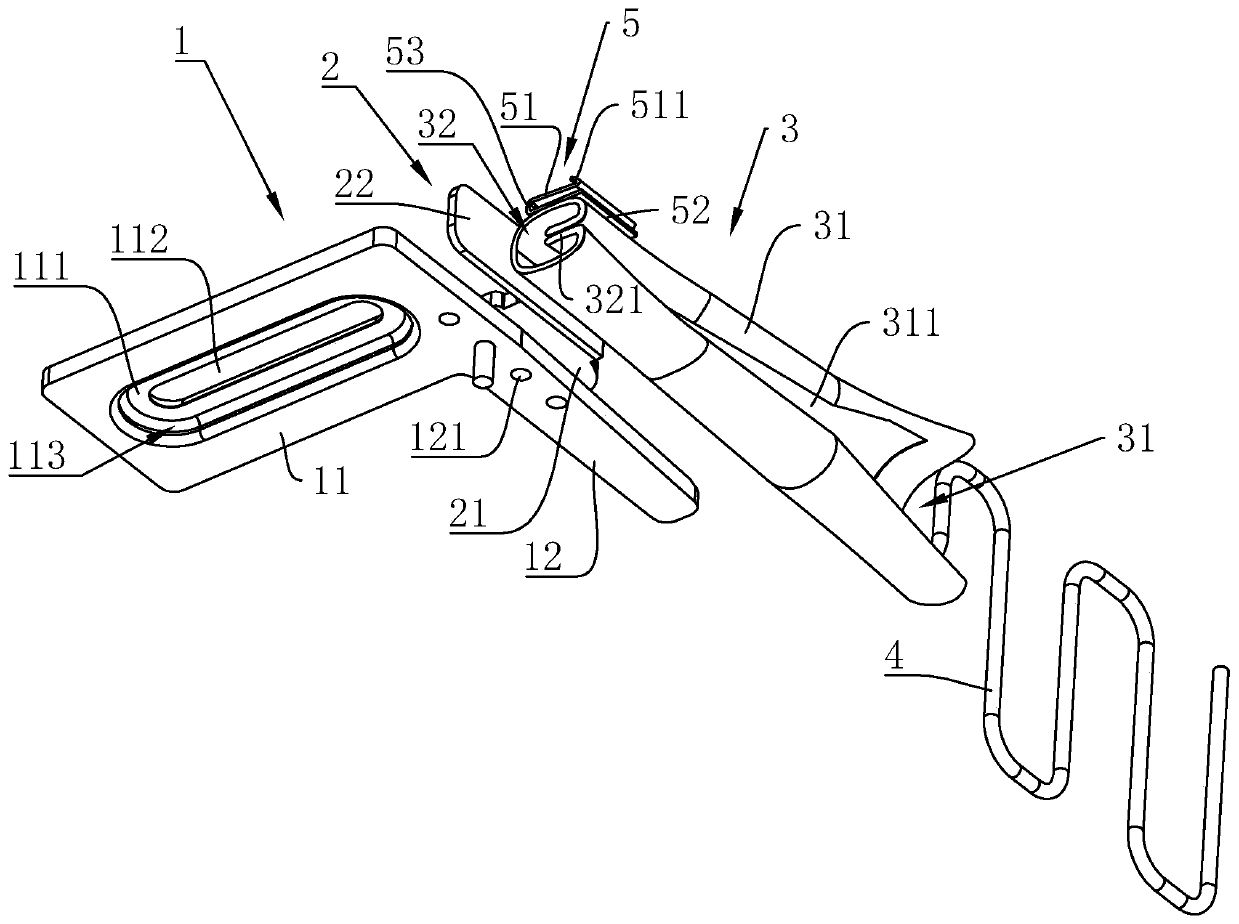

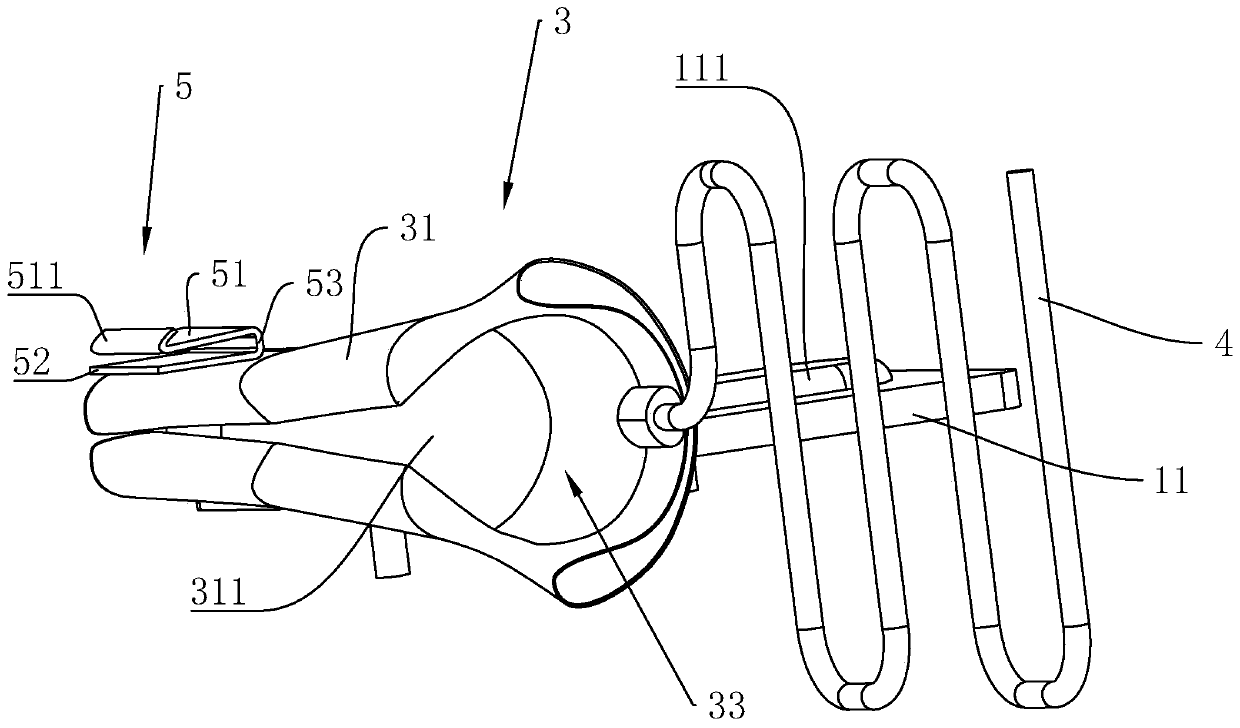

[0039] Cloth edge curlers, such as figure 1 As shown, it includes a fixed seat 1 for fixing on the operating table of the sewing machine and a curler 3 , and the curler 3 is fixedly connected with the fixed seat 1 through a connecting piece 2 .

[0040] like figure 1 , figure 2As shown, the fixing seat 1 is a flat plate structure and the body is "L"-shaped, which are respectively the fixing part 11 and the adjusting part 12, and the fixing part 11 and the adjustin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap