Fourth-generation efficient long-stroke long-life intelligent mechanical electrical and hydraulic oil pumping unit

A long-stroke, long-life technology, used in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., which can solve the problems of short life of cooling devices and hydraulic mechanisms, inability to adapt to oil fields, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

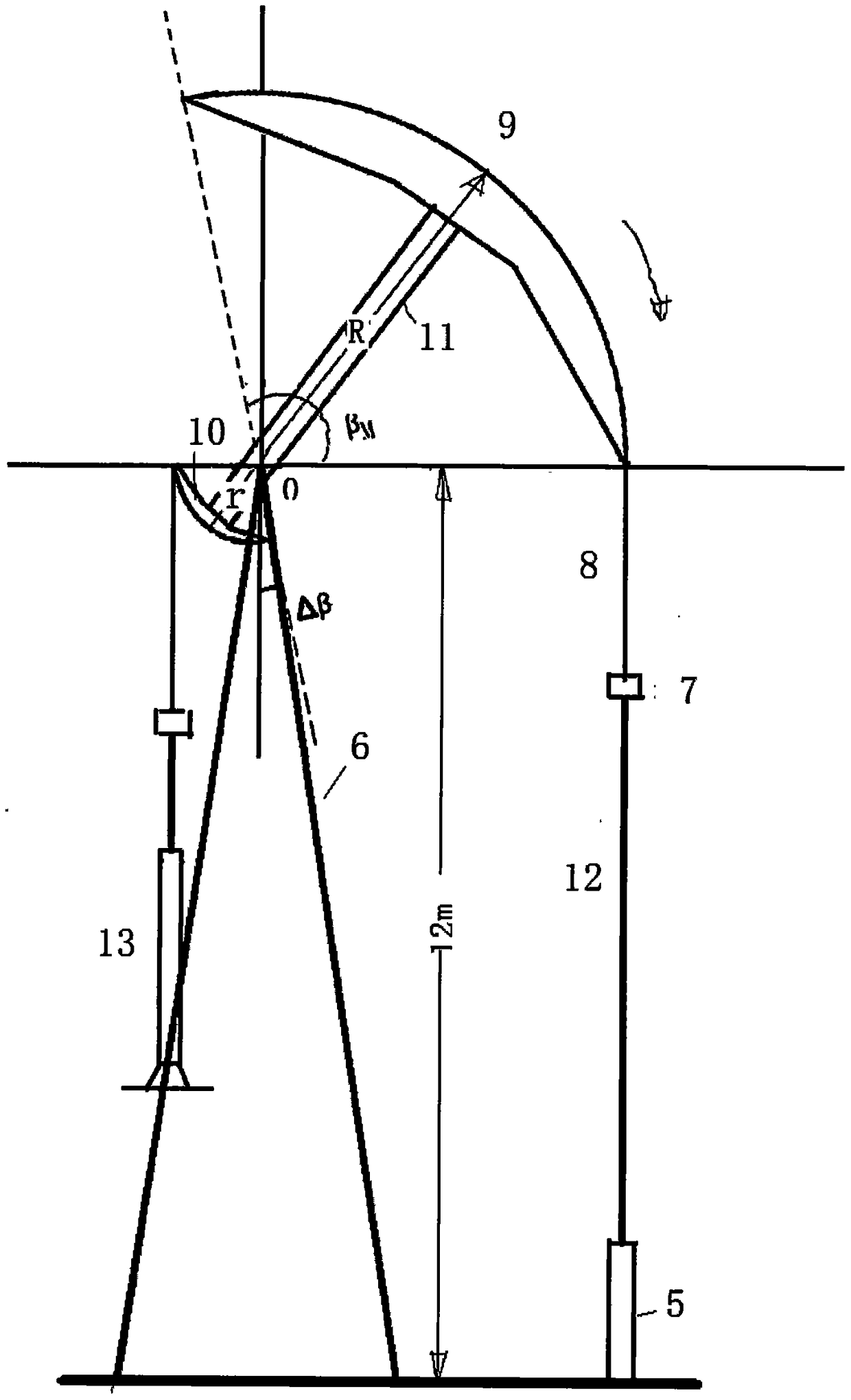

[0017] figure 1 Among them, 9 is the front donkey head, 10 is the rear donkey head, 11 is the beam, 12 is the sucker rod, 8 is the steel wire rope, 7 is the connector, 6 is the bracket, 5 is the Christmas tree, R is the rotation radius of the front donkey head, R=6m, r is the radius of the back donkey head, r=1.2m, β M is the maximum rotation angle, β M =95.5°, Δβ=5.5°. Wherein O point is the supporting point of the beam, obviously the back donkey head pulled by the oil cylinder 13 makes the beam rotate around the vertical plane, so that the front donkey head 9 pulls the sucker rod 12 to move up and down by the wire rope 8 to achieve the oil pumping purpose. But front donkey head 9 will enter support 6 part when reaching bottom dead center. Among them, point O is 12m above the ground.

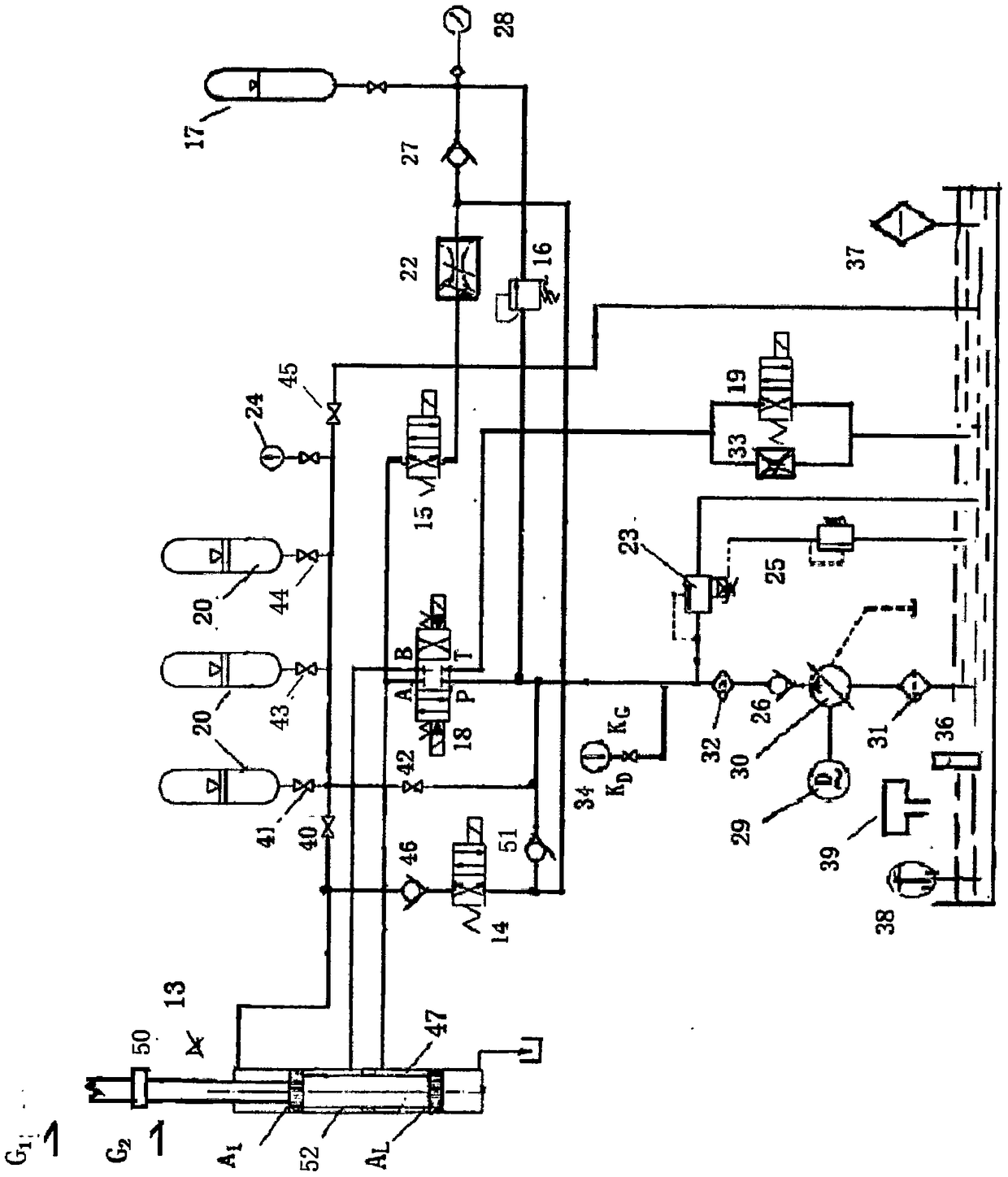

[0018] Hydraulic system of the present invention sees figure 2 . Among them, 13 is an oil cylinder, 14 (power on), 15 (power off), 19 (power off) is an electromagnetic reversing valve, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com