An abnormal detection method of a temperature and humidity sensor

A temperature and humidity sensor and anomaly detection technology, applied in the direction of instruments, etc., can solve the problems of wrong comparison between measurement data and CRC check code, control instrument out of control, catastrophe, etc., and achieve the effect of preventing data confusion and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

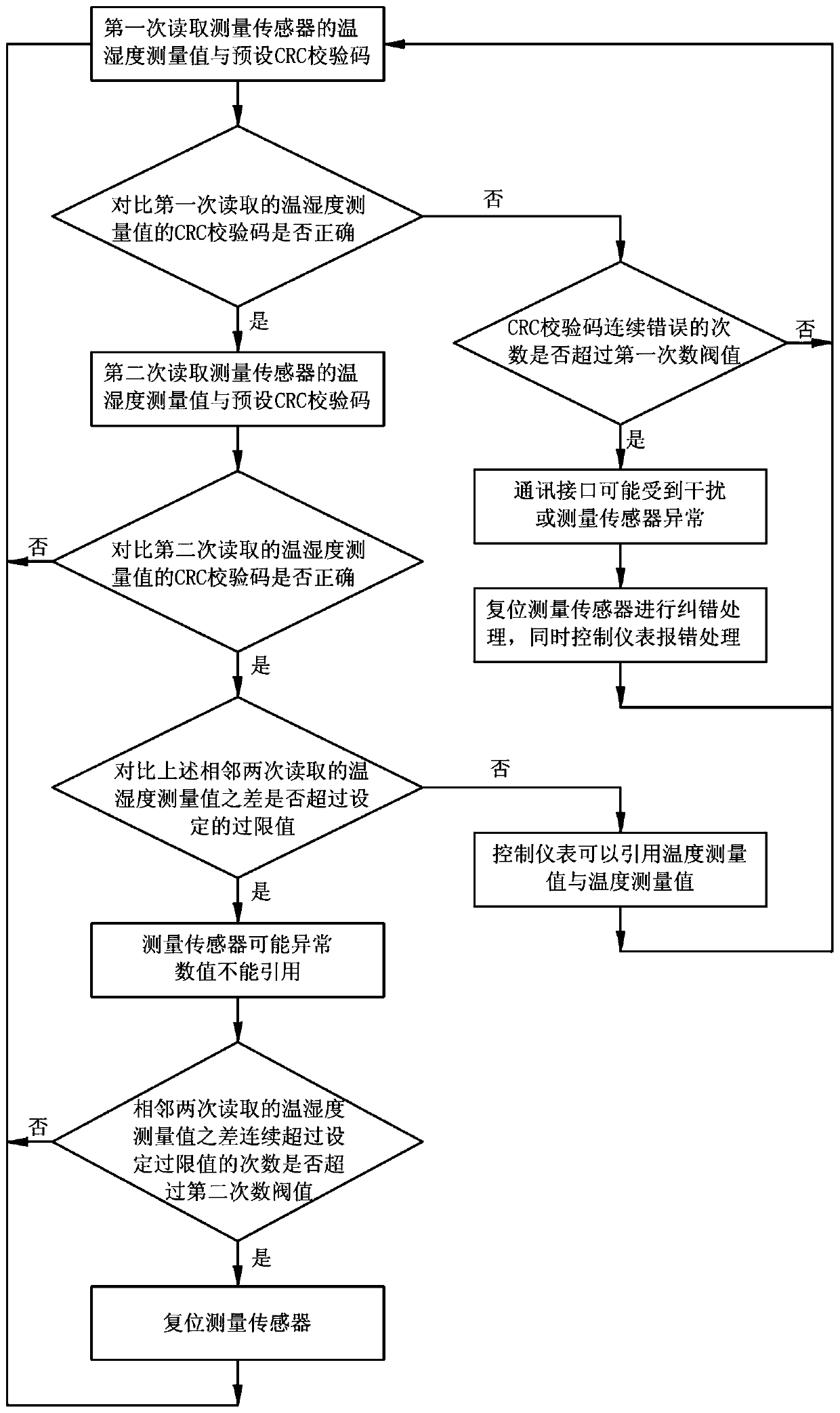

[0030] see figure 1 , is a temperature and humidity sensor anomaly detection method as the best embodiment of the present invention, is to detect whether the temperature and humidity measured by the control instrument are abnormal, the control instrument at least includes a measurement sensor and a control system, and the measurement sensor is used for Measuring temperature and humidity, wherein the measurement sensors include a temperature sensor and a humidity sensor for measuring temperature and humidity respectively, wherein the temperature and humidity measurement values include temperature measurement values and humidity measurement values.

[0031] Described method has included the following steps:

[0032] Step 1, read the temperature and humidity measurement value and the preset CRC check code of the measurement sensor for the first time; that is, read the temperature measurement value and humidity measurement value measured by the measurement sensor for the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com