Fixing method and device of display screen backlight module

A display module and backlight module technology, applied in the display field, can solve problems such as low pass rate, long production time, serious Mura, etc., and achieve the effect of eliminating positive pressure and tolerance accumulation, and reducing longitudinal pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

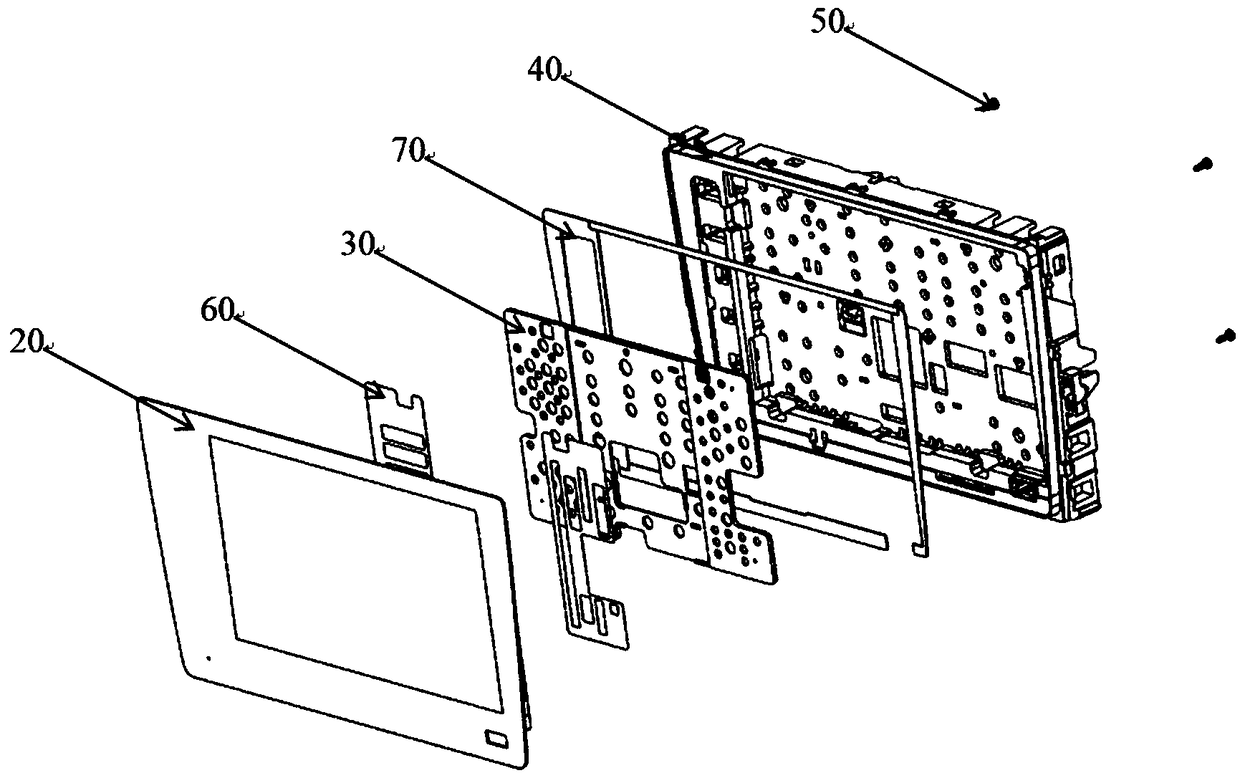

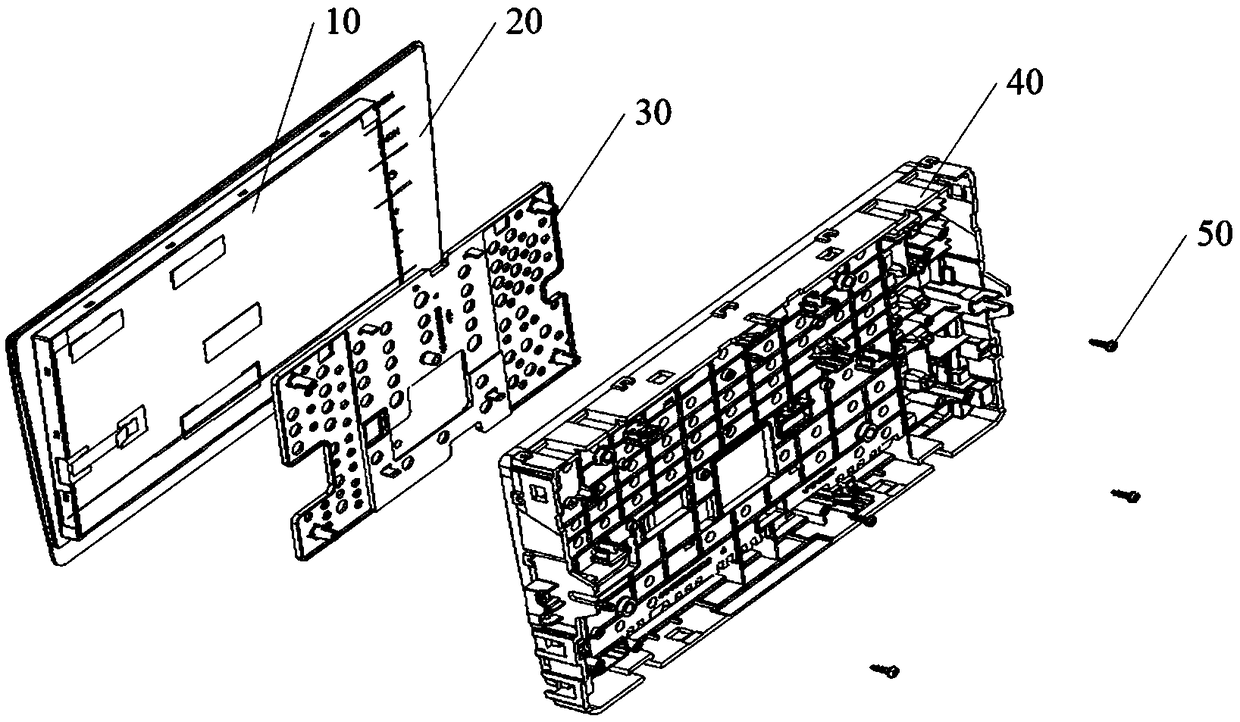

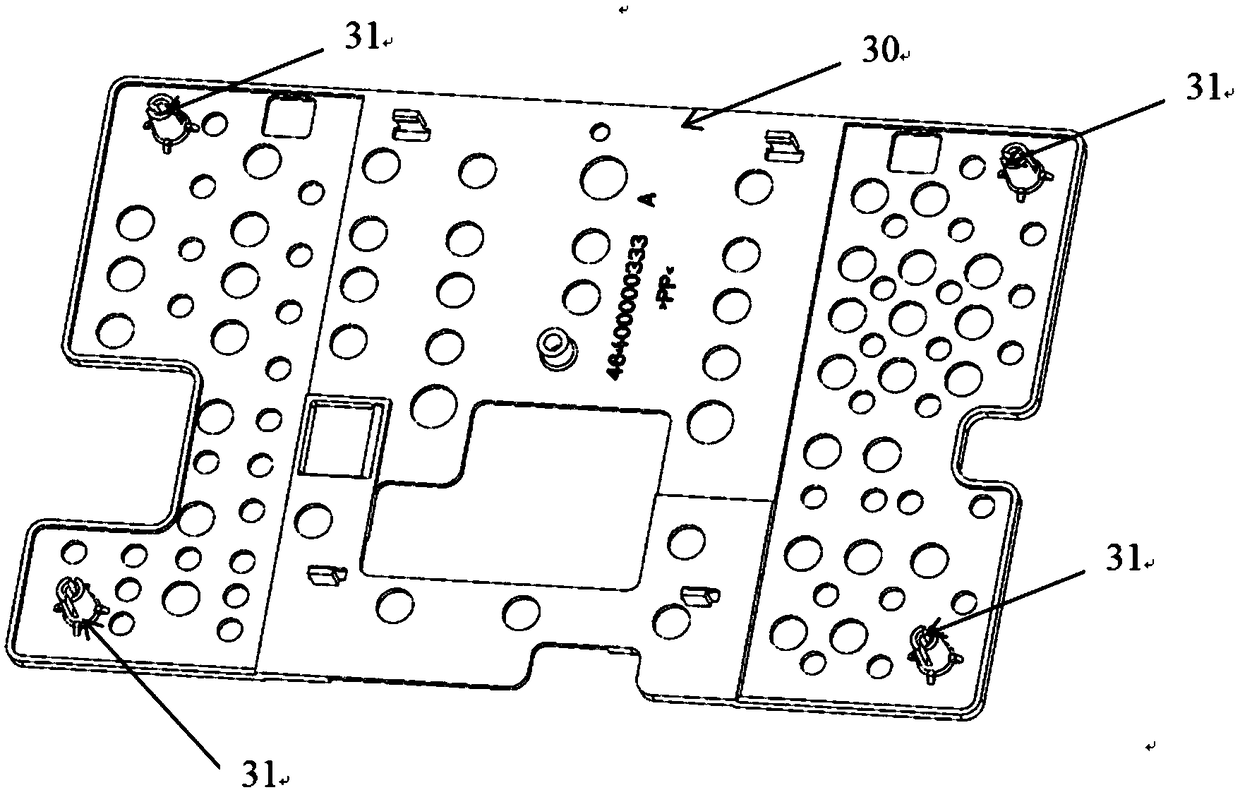

[0031] This embodiment provides a fixing device for a display backlight module, such as figure 1 and 2 As shown, it includes a display screen module 20 with a backlight box 10, a backlight bracket 30, a panel 40 and screws 50, the backlight bracket 30 is bonded to the backlight box 10 by double-sided adhesive 60, and the display screen module Group 20 and panel 40 are pasted and fixed by double-sided adhesive tape 70, wherein, as image 3 As shown, the back of the backlight bracket 30 is provided with a plurality of screw posts 31, such as Figure 4 As shown, the screw post 31 is cut into at least two pieces, but not limited to, the screw post 31 can also be cut into four pieces. Such as Figure 5 As shown, the back of the panel 40 is provided with a hole 41 adapted to the screw post 31. When in use, as Figure 6 As shown, the screw post 31 is nested in the hole 41 , and the screw 50 is screwed into the screw post 31 . Such as Figure 7 As shown, it may be, but not limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com