Autoclaved aerated concrete autoclaving process monitoring system

A technology of autoclave gas filling and monitoring system, applied in general control system, control/regulation system, electrical program control, etc., can solve the problems of autoclave explosion, substandard product quality, etc., and achieve the effect of ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

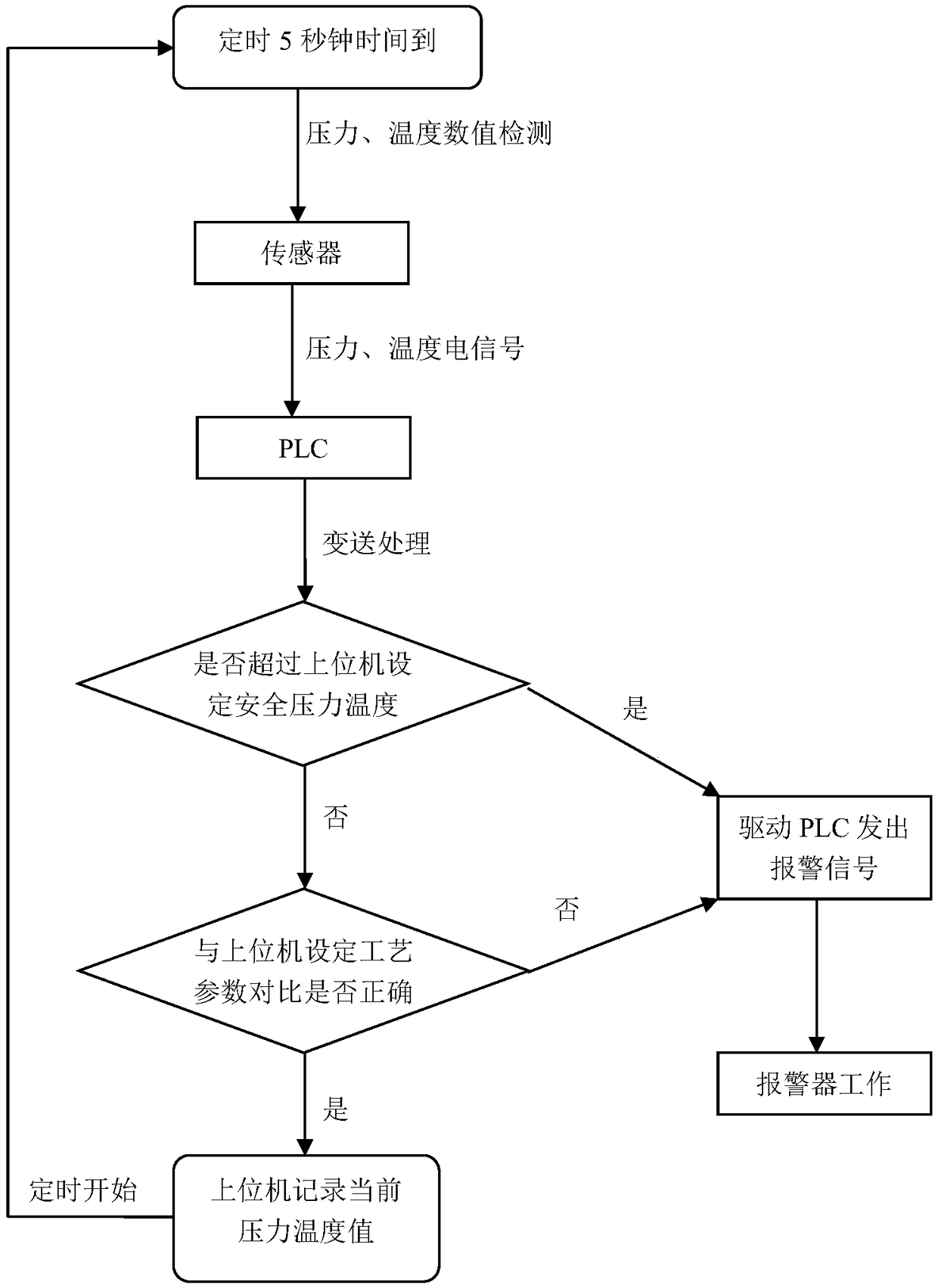

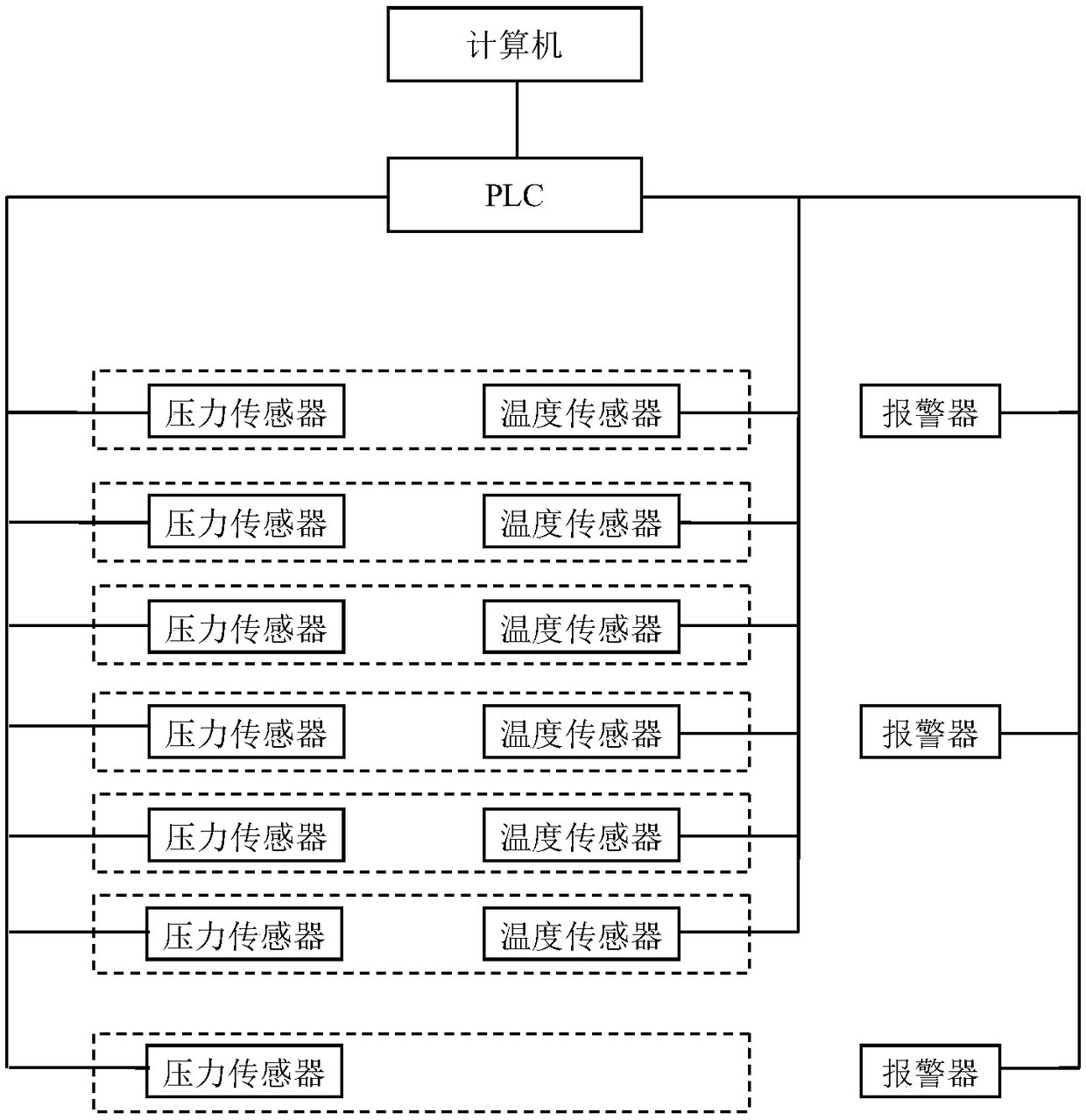

[0033] This system records the pressure and temperature of the autoclave and boiler in the gas filling production line in real time. At the same time, according to the steaming system, the parameters are set into the computer, and the control alarm command is issued in real time during the steaming process to remind the workers to operate. When the operation is improper, the computer sends out an alarm instruction.

[0034] The original components of the system:

[0035] 1. Radiator, one for each autoclave, one for the boiler, 7 in total, one end is connected to the inner cavity of the autoclave, and the other end is connected to the pressure sensor, which plays a cooling role for the pressure sensor to detect the working pressure of the autoclave.

[0036] 2. Pressure sensor, one for each autoclave and one for the boiler, 7 in total, used to detect the pressure value, and convert the pressure data into a corresponding electrical signal for detection and recording.

[0037] 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com