A Design Method for Mixed Height Cell Layout Based on Minimum Implanted Area Constraint

A technology of regional constraints and layout design, applied in computer-aided design, calculation, instrument, etc., can solve the problem of multi-threshold voltage cells violating MIA constraints, and achieve the effect of optimizing layout results, compressing regional area, and ensuring convergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further explained below with reference to the accompanying drawings and specific embodiments.

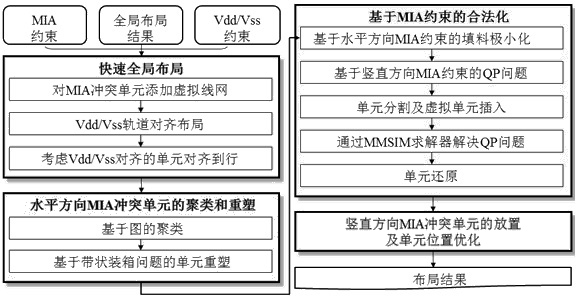

[0011] The present invention provides a mixed-height cell layout design method based on minimum implantation area constraints, which comprises the following steps:

[0012] Step S1: quick global layout;

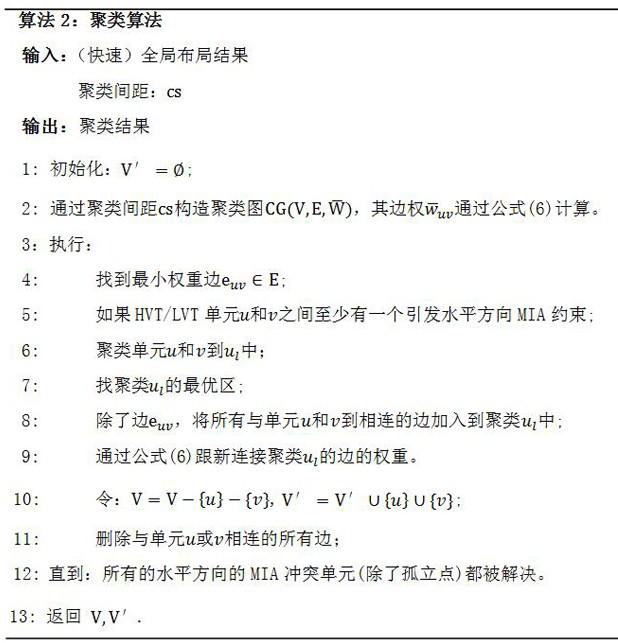

[0013] Step S2: apply graph-based clustering and band-packing-based reshaping to the MIA conflicting units in the horizontal direction to cluster and compress the MIA conflicting units in the horizontal direction;

[0014] Step S3: Based on the legalization of the MIA constraint, solve the packing minimization and process the MIA constraint unit in the vertical direction;

[0015] Step S4: The locations of cells are allocated and optimized.

[0016] In an embodiment of the present invention, step S1 includes the following steps:

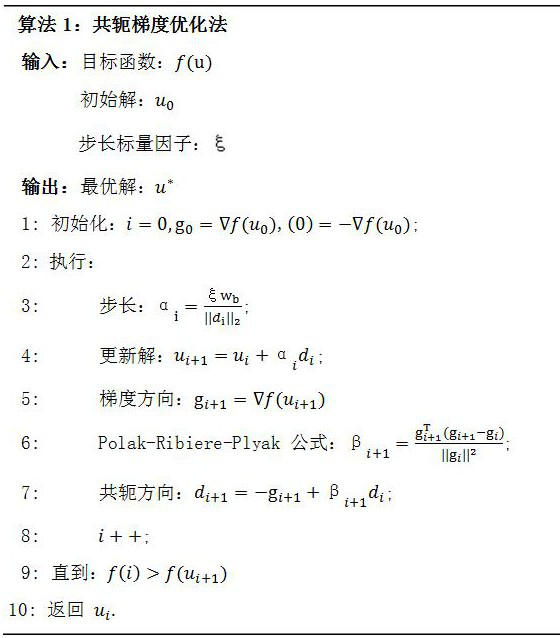

[0017] Step S11: Given an n standard unit C={c 1 ,c 2 ,…,c n } and m lines E={e 1 ,e 2 ,…,e m } The global ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com