Less-packing arrangement structure and method for natural-ventilation counter-flow wet cooling tower

A technology of wet cooling and natural ventilation, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problem of large cooling tower area and filler consumption, uneven distribution of air velocity, humidity and temperature , The ability of the cooling tower to enter the air has not been brought into play, etc., to achieve the effect of reducing the project cost, reducing the amount of filler used, and reducing the heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

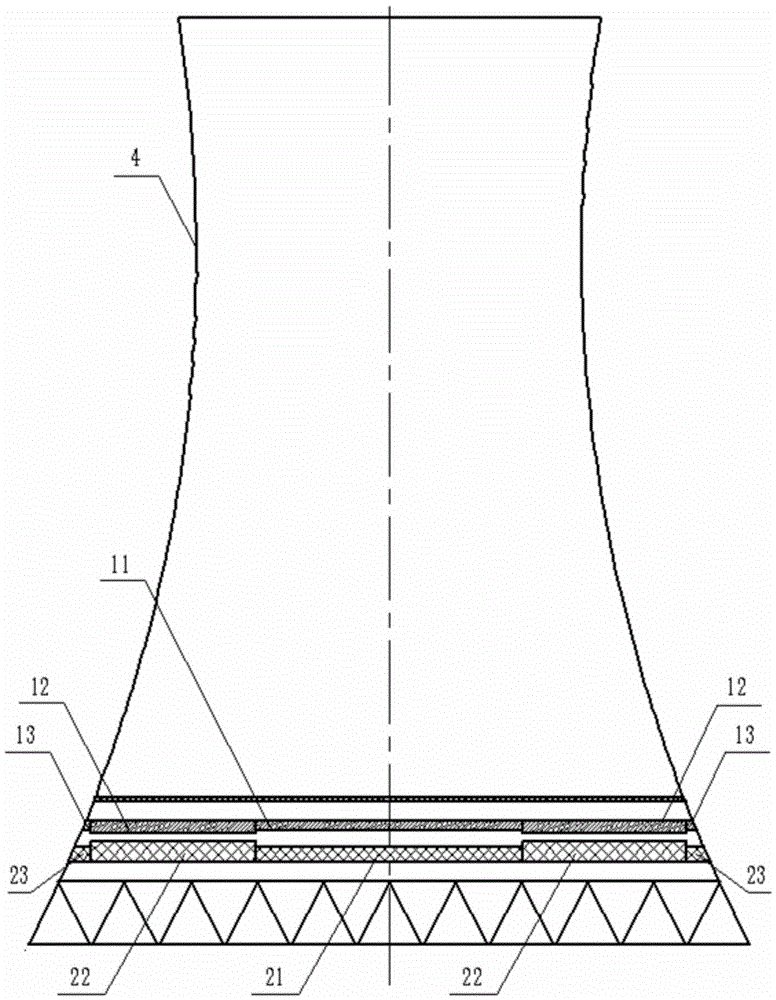

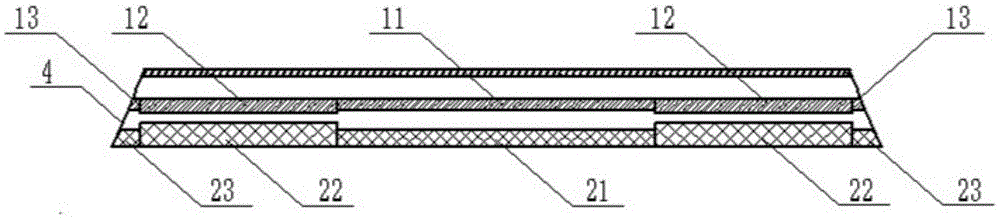

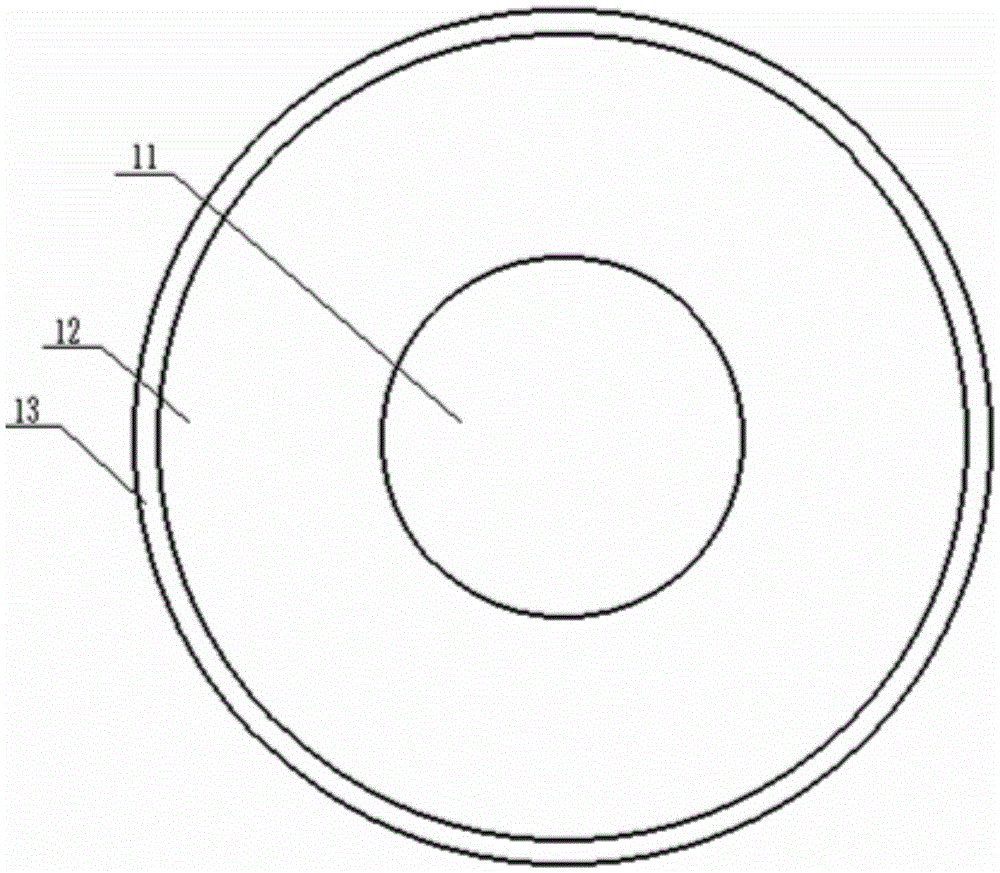

[0025] In this embodiment, the arrangement structure of less packing in the natural ventilation counter-flow wet cooling tower is: the water distribution and packing system of the cooling tower is set as follows: the tower is divided into N water distribution areas and N packing areas, and the N water distribution areas include the center of the tower as The center area of the circle center, and N-1 annular areas located outside the center area and at different radial positions; the N water distribution areas and the N filling areas are in one-to-one correspondence in position; the one-to-one correspondence is It means that the area and position of the i-th filling area and the i-th water distribution area are the same, i is a positive integer, and i=1, 2...N; the water spray density between different water distribution areas is different, and the different filling areas The fillers between them are arranged at different heights.

[0026] In the specific implementation, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com