Water saving method applied to turboset

A technology of steam turbine generator set and steam turbine, which is applied in the direction of engine cooling, electric components, engine components, etc., can solve the problems such as the temperature rise of cooling water, and achieve the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

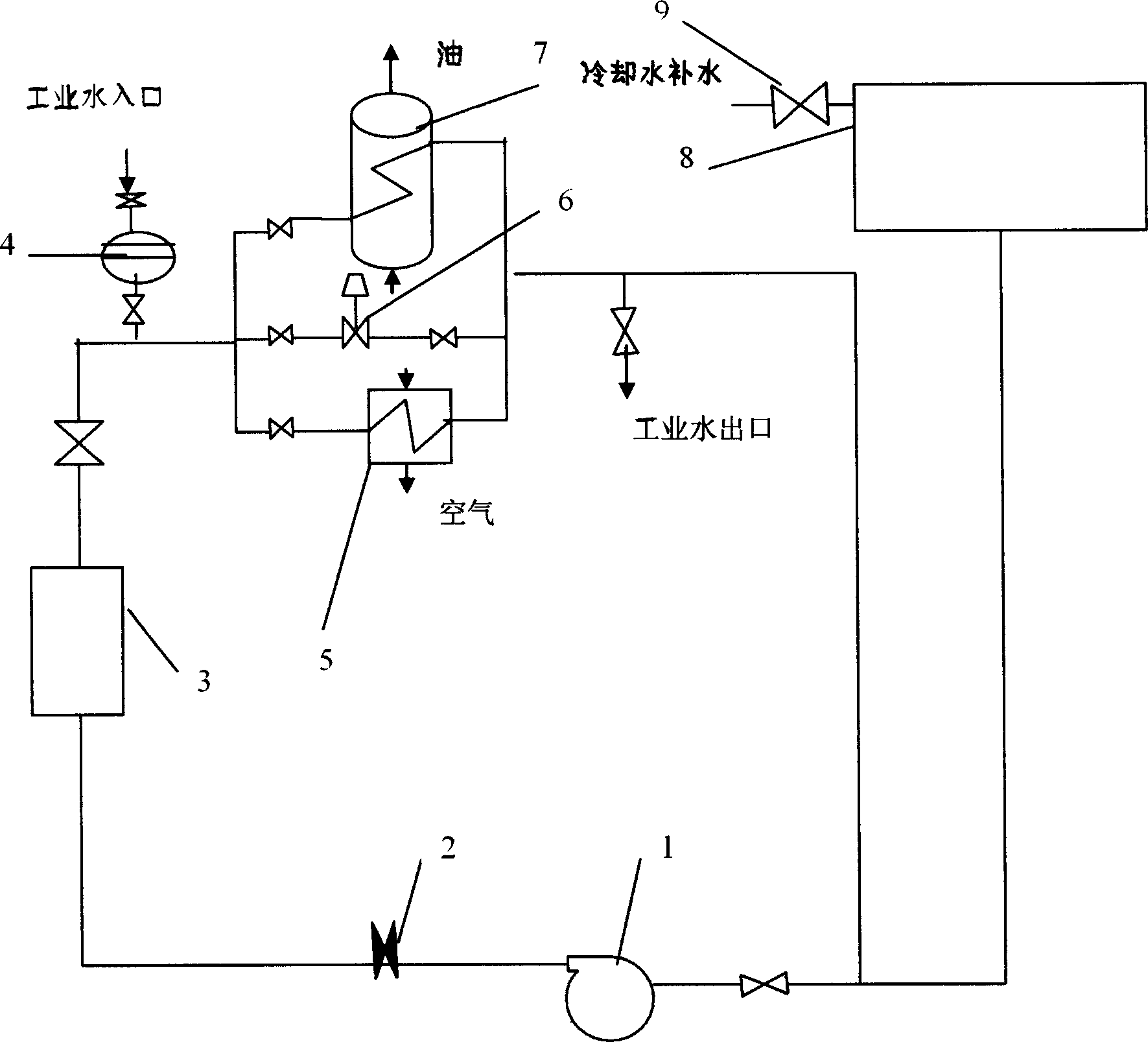

[0008] In the cooling water system of the present invention, the cooling water adopts condensed water or deoxygenated water, and the cooling water with higher temperature is pressurized into the chiller (3) through the cold water pump (1), and the check valve (2) ensures that the cooling water does not flow back , the cooling water transfers heat in the chiller (3) and turns it into cold water at 7~20°C, and the cooling water with a lower temperature enters the air cooler (5), and the oil cooler (7) will enter the air cooler (5) The heat of the air and the oil entering the oil cooler (7) is taken away, the temperature of the cooling water rises, and the cooling water is re-sucked by the cooling water pump (1), so that the closed circuit operation ensures that the temperature of the oil and the temperature of the air are within the specified range It meets the requirements of the cooling of the oil supply system of the steam turbine and the ventilation and cooling system of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com