Moisture absorbing device for transformer

A moisture absorbing device and transformer technology, which is applied in transformer/inductor cooling, chemical instruments and methods, gas treatment, etc., can solve the problems of deteriorating sealing effect of moisture absorbers, waste of materials, heavy maintenance workload, etc., and achieve easy opening And closing the movable door, ensuring the sealing effect, and the effect of flexible and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

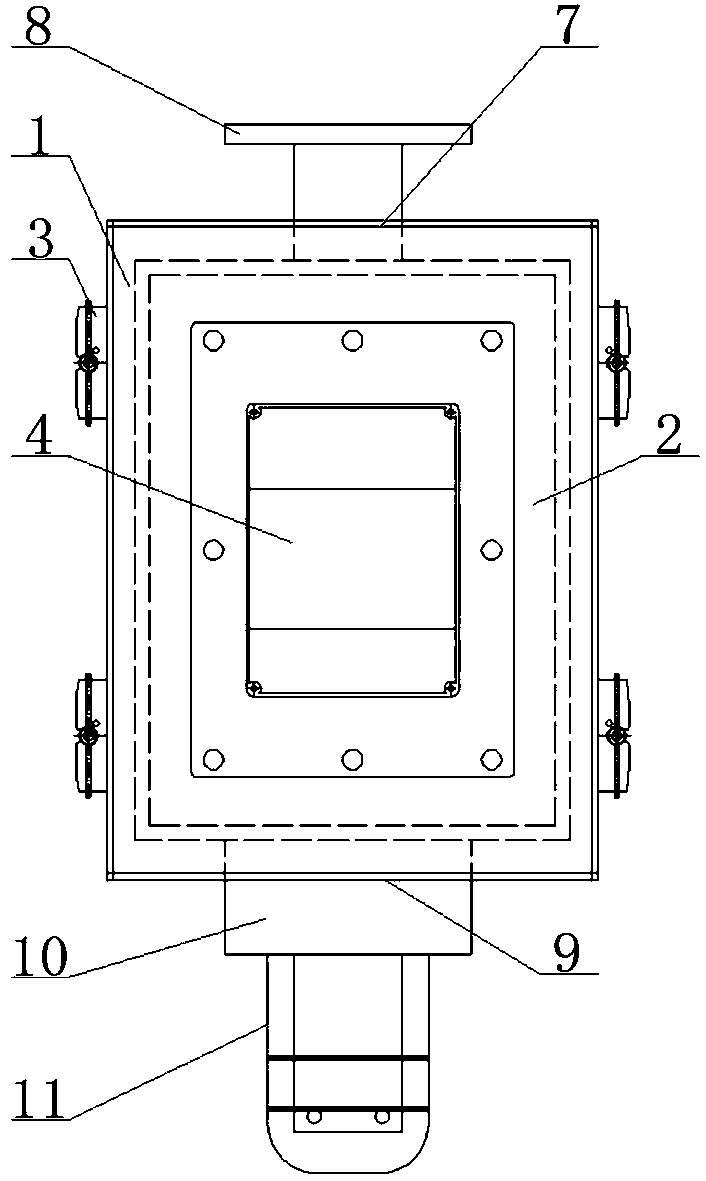

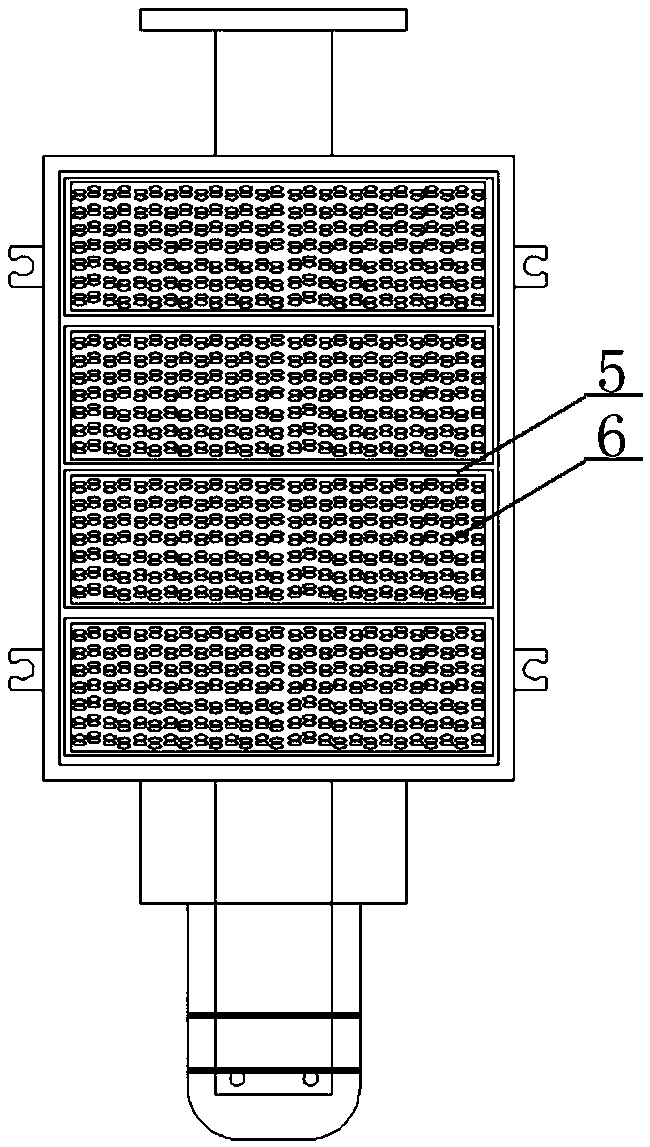

[0024] Such as figure 1 and figure 2 As shown, the hygroscopic device for a transformer of the present invention includes a moisture absorber box 1, and a movable door 2 is arranged on the front of the moisture absorber box 1, and the outer wall of the moisture absorber box 1 is connected with the movable door by adjusting the hasp 3. 2 connection fixed;

[0025] The movable door 2 is also provided with a transparent observation window 4;

[0026] A plastic box 5 is placed inside the box of the dehumidifier box 1, the surface of the plastic box 5 is provided with through holes, and the inside of the plastic box 5 is also provided with a color-changing silica gel 6;

[0027] The top of the dehumidifier box 1 is provided with a first connecting hole 7, and the first connecting hole 7 is connected to the flange 8 through a connecting pipe;

[0028] The bottom of the moisture absorber box 1 is provided with a second connection hole 9 , and an oil cup interface 10 is provided o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com