Printing machine

A printing machine and frame technology, which is applied in the field of printing machines for printing shoe sole materials, can solve problems such as troublesome die printing wheel replacement process and difficulty in pattern color adjustment, and achieves the effects of convenient adjustment process, reduced operation difficulty, and reliable contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

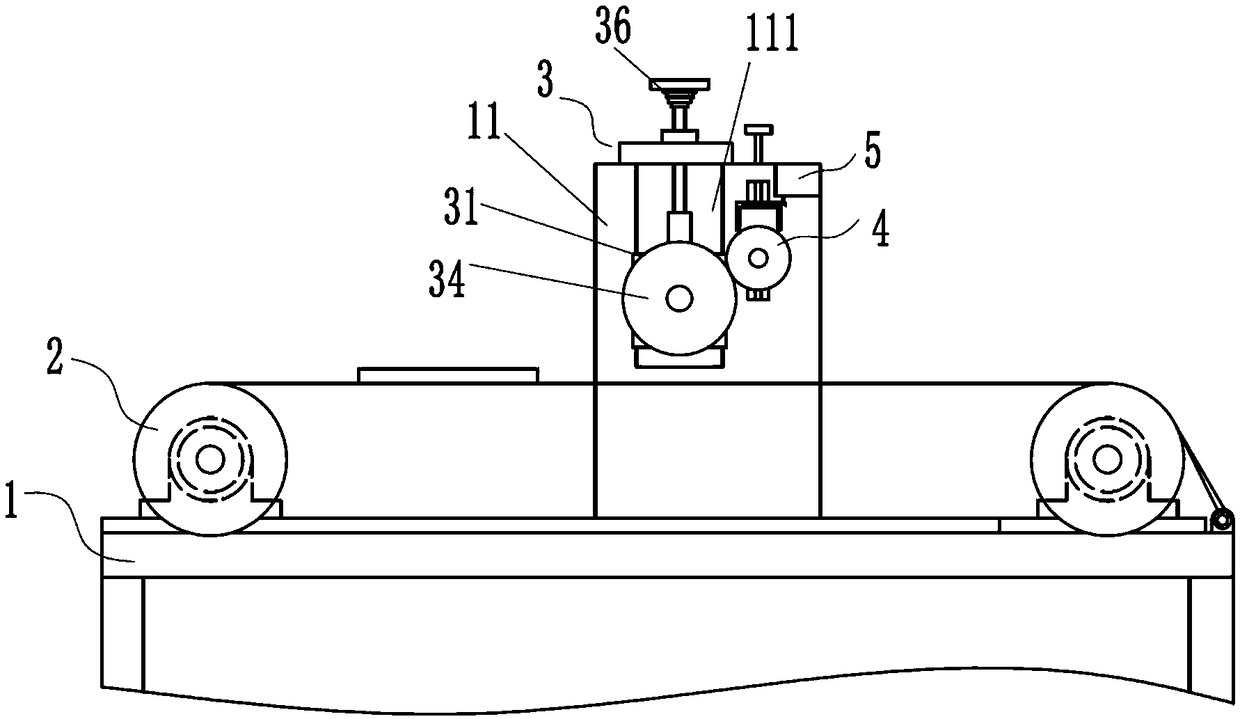

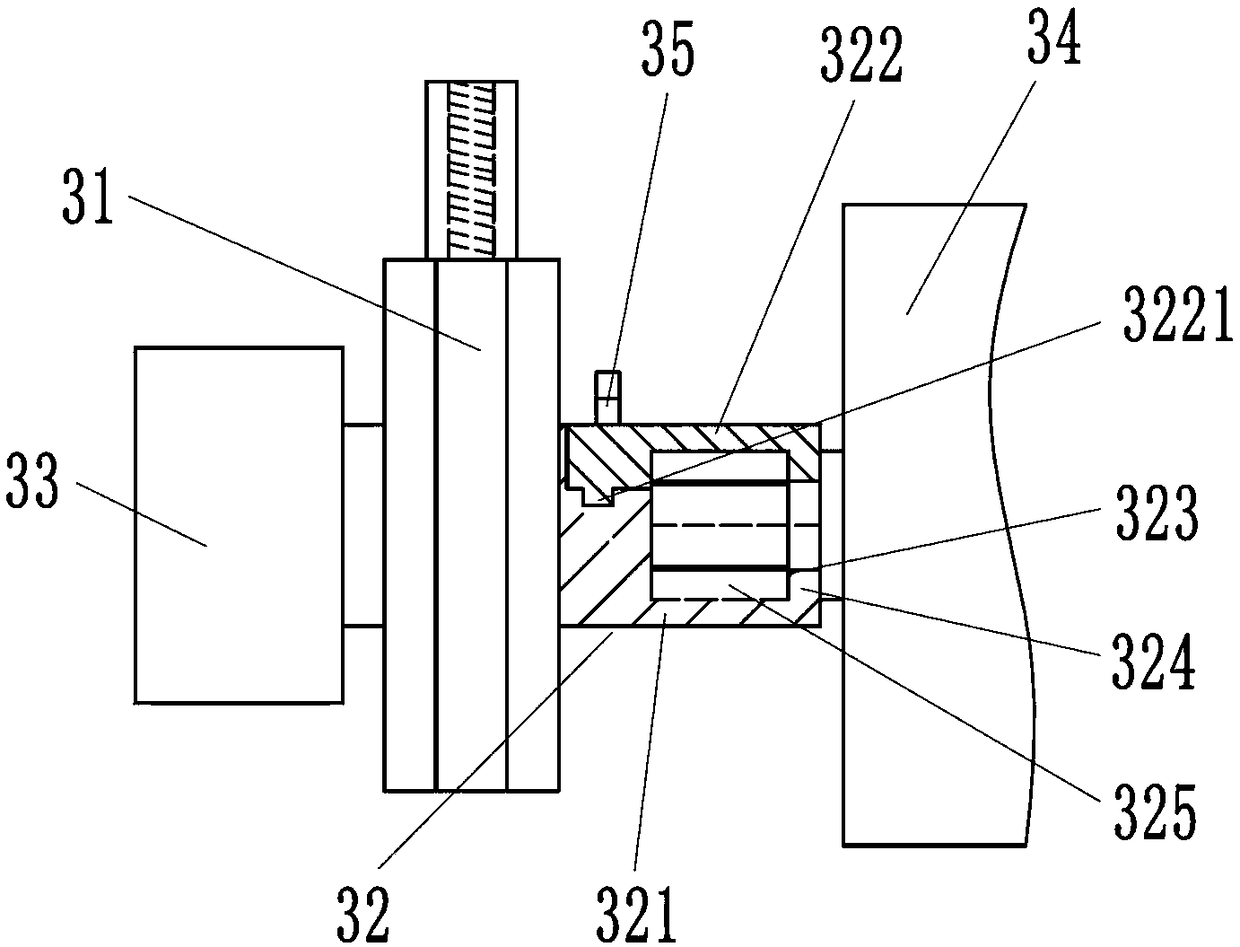

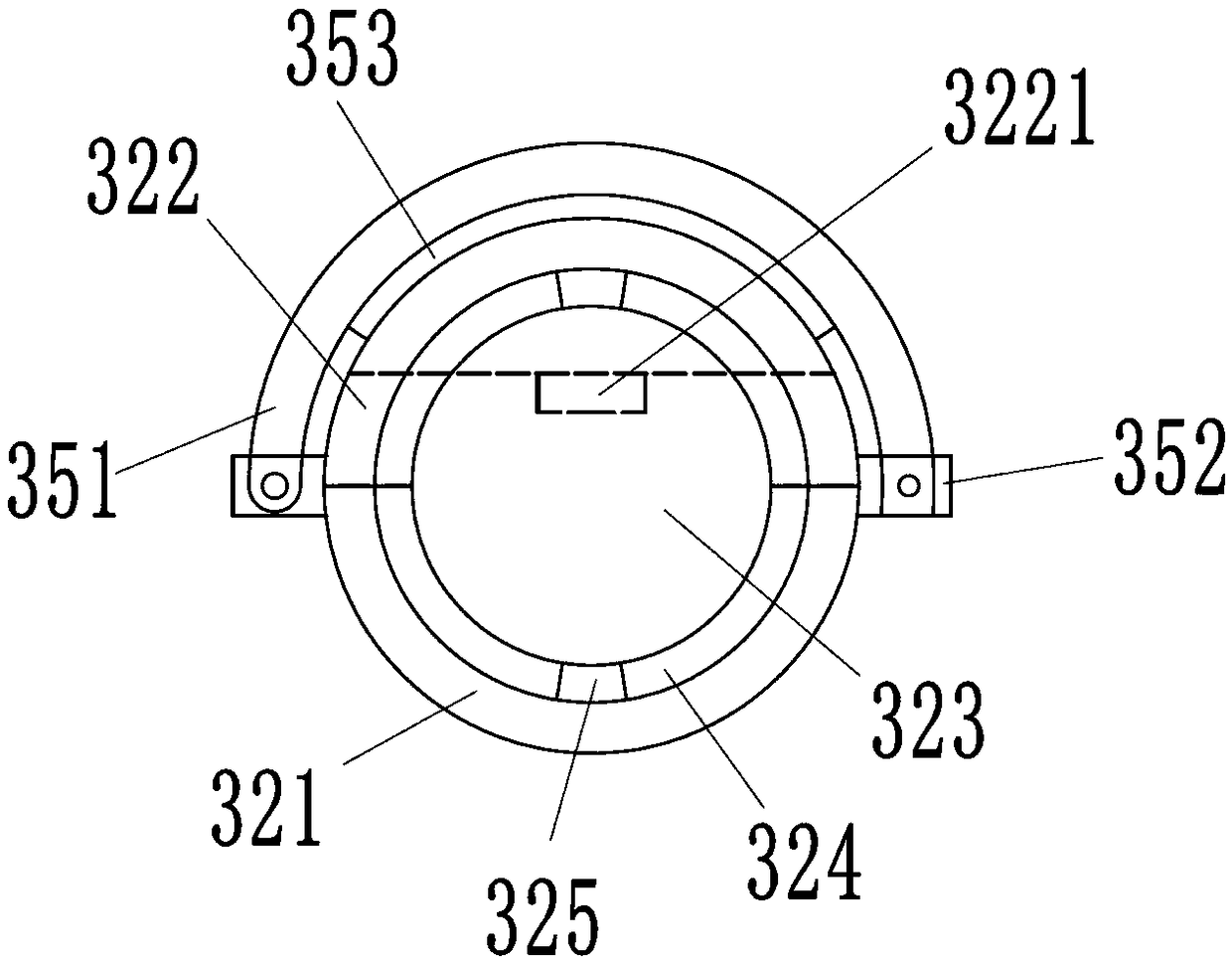

[0028] Refer below Figure 1 to Figure 6 To further explain this application, such as figure 1 and figure 2 A printing machine shown includes a frame 1 and a feeding mechanism 2 arranged on the frame 1, a stamping mechanism 3, and an ink tank 5, and the stamping mechanism 3 includes a lifting slider 31, a main shaft 32, Motor 33, embossing wheel 34 and locking mechanism 35, described lift slide block 31 is connected with the first guide groove 111 on the side plate 11 of described frame 1 that is positioned at and is slidably connected, and described lift slide block 31 is pivotally connected with The screw mandrel 36 on the frame 1 is threadedly connected, and the main shaft 32 includes a main shaft body 321 and a movable body 322, and the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com