Diversion type support grid and fluidized bed reactor for reactor catalyst bed

A catalyst bed, supporting grid technology, used in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of catalyst leakage, cracking, and easy coking of catalysts, so as to reduce frictional resistance and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] This embodiment is used to illustrate the diversion type supporting grid of the present invention.

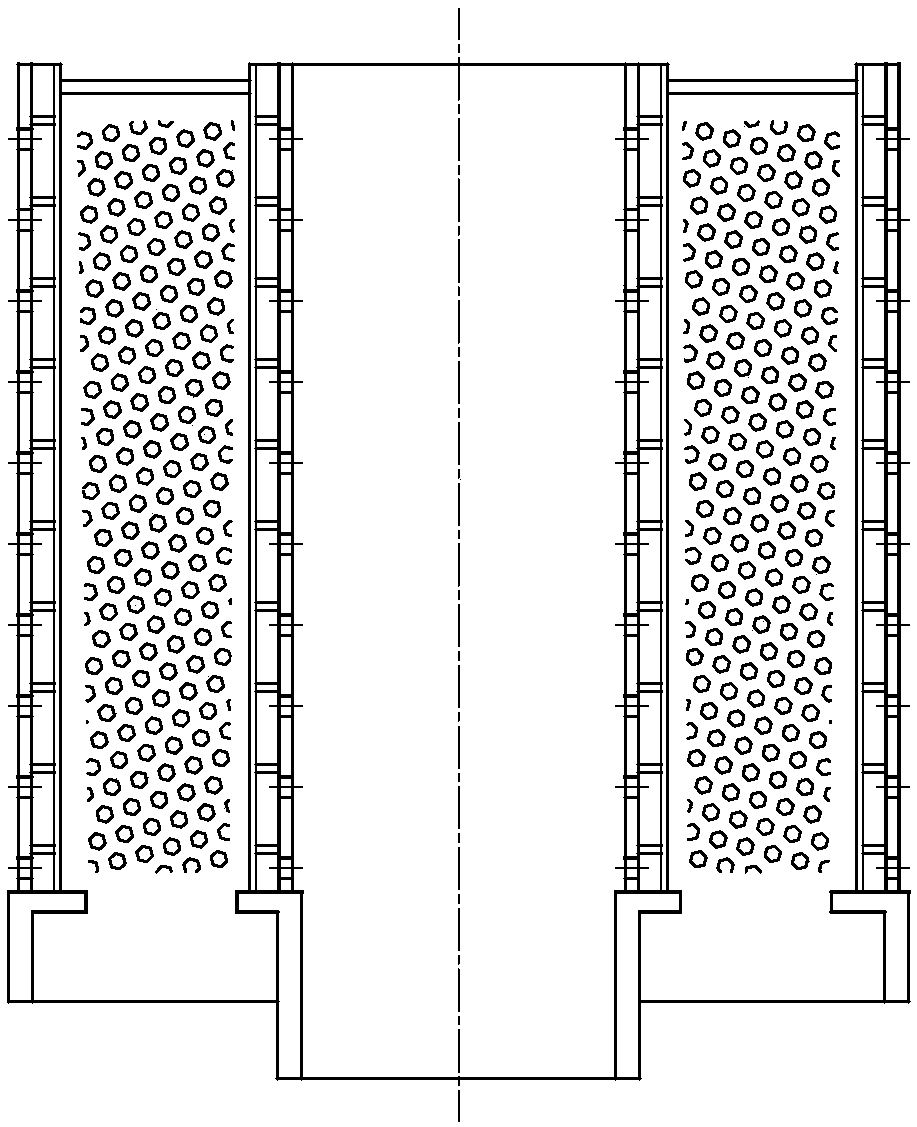

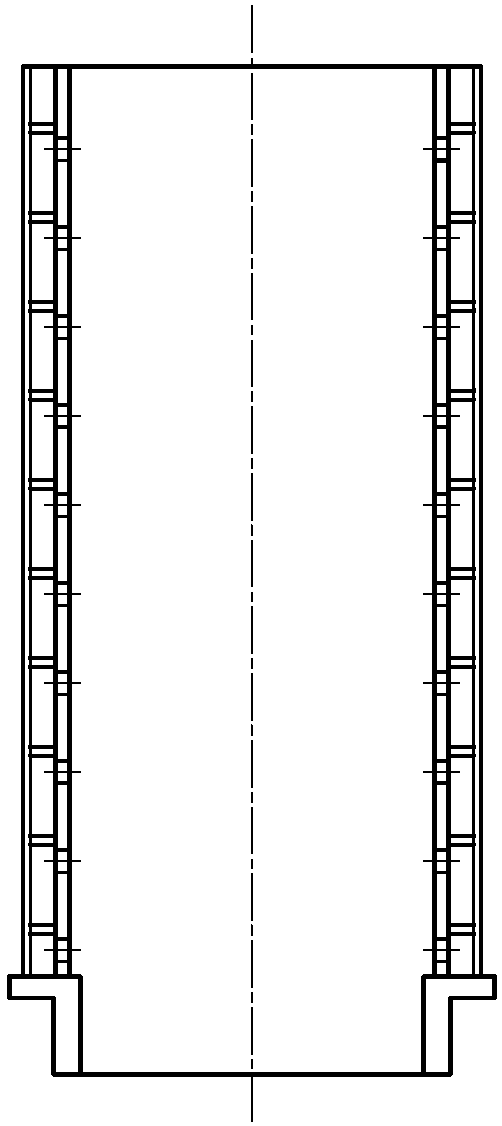

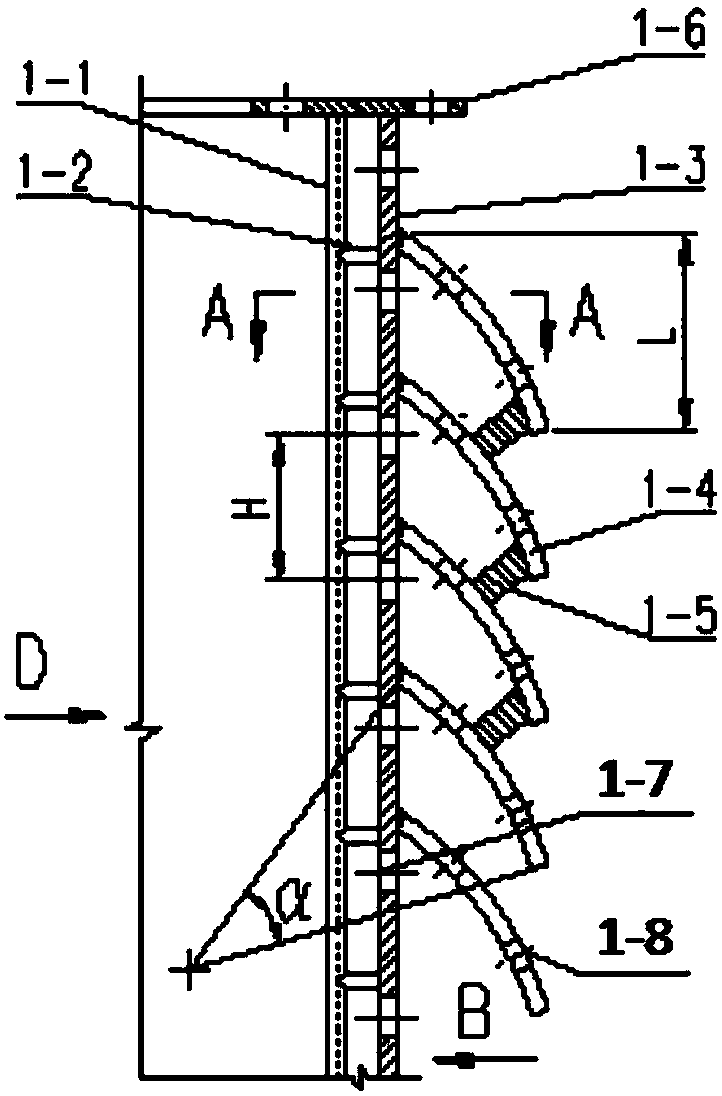

[0063] The diversion support grid is a double-layer cylindrical structure, such as image 3 with Figure 5 As shown, it includes a distribution cylinder 1-1, a support bar 1-2, a contact cylinder 1-3, and a connecting ring plate 1-6 at the end, the distribution cylinder 1-1 and the contact cylinder 1. -3 are arranged in parallel, the support bar 1-2 is located between the distribution cylinder 1-1 and the contact cylinder 1-3, and the contact cylinder 1-3 is adjacent to the catalyst bed 3,

[0064] The contact cylinder 1-3 is provided with evenly distributed multiple circles of channel holes 1-7, and on its side adjacent to the catalyst bed 3, a baffle plate is provided above each circle of channel holes 1-7 1-4. The baffle 1-4 is a circular arc-shaped hood structure, the convex surface of which directly contacts the catalyst bed 3, the concave surface faces the contact cylin...

Embodiment 2

[0070] This embodiment is used to illustrate the diversion type supporting grid of the present invention.

[0071] The diversion support grid is a double-layer cylindrical structure, such as Figure 4 with Image 6 As shown, it includes a distribution cylinder 1-1, a support bar 1-2, a contact cylinder 1-3, and a connecting ring plate 1-6 at the end, the distribution cylinder 1-1 and the contact cylinder 1. -3 are arranged in parallel, the support bar 1-2 is located between the distribution cylinder 1-1 and the contact cylinder 1-3, and the contact cylinder 1-3 is adjacent to the catalyst bed 3,

[0072] The contact cylinder 1-3 is provided with evenly distributed multiple circles of channel holes 1-7, and on its side adjacent to the catalyst bed 3, a baffle plate is provided above each circle of channel holes 1-7 1-4. The baffle 1-4 is a circular arc-shaped hood structure, the convex surface of which directly contacts the catalyst bed 3, the concave surface faces the contact cylin...

Embodiment 3

[0078] This example is used to illustrate the fluidized bed reactor of the present invention.

[0079] Such as Picture 12 with Figure 13 As shown, the fluidized bed reactor includes an inner cylinder grid 1, an outer cylinder grid 2, a shell 4, an inlet pipe 6, a gas distributor 7, an outlet pipe 5, a catalyst feed pipe 9 and a catalyst discharge pipe 10.

[0080] The shell 4, the outer cylindrical grille 2 and the inner cylindrical grille 1 are nested in sequence along the radial direction, and the inner cylindrical grille is supported by a support 8 provided on the inner side wall and / or bottom of the housing 4 1 is connected to the outer cylindrical grille 2, the inlet pipe 6 is arranged at the bottom of the housing 4, the gas distributor 7 is located above the inlet pipe 6, and its axis is aligned with the inner cylindrical grille 1. The axes of the outer cylindrical grid 2 and the shell 4 coincide, the outlet pipe 5 is arranged on the top or side of the shell 4, and the cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com