Six-connecting-rod control device for heat-insulating cover of hot-metal bottle

A control device and a six-link technology, applied in the field of the control device of the hot metal tank insulation cover, can solve the problems of unsafe actions, unreliable equipment operation, large floor space, etc., and achieve convenient and fast opening and closing operations, and obvious environmental protection and energy saving effects , Improve the effect of the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The content of the invention will be further described below in conjunction with the embodiments of the accompanying drawings.

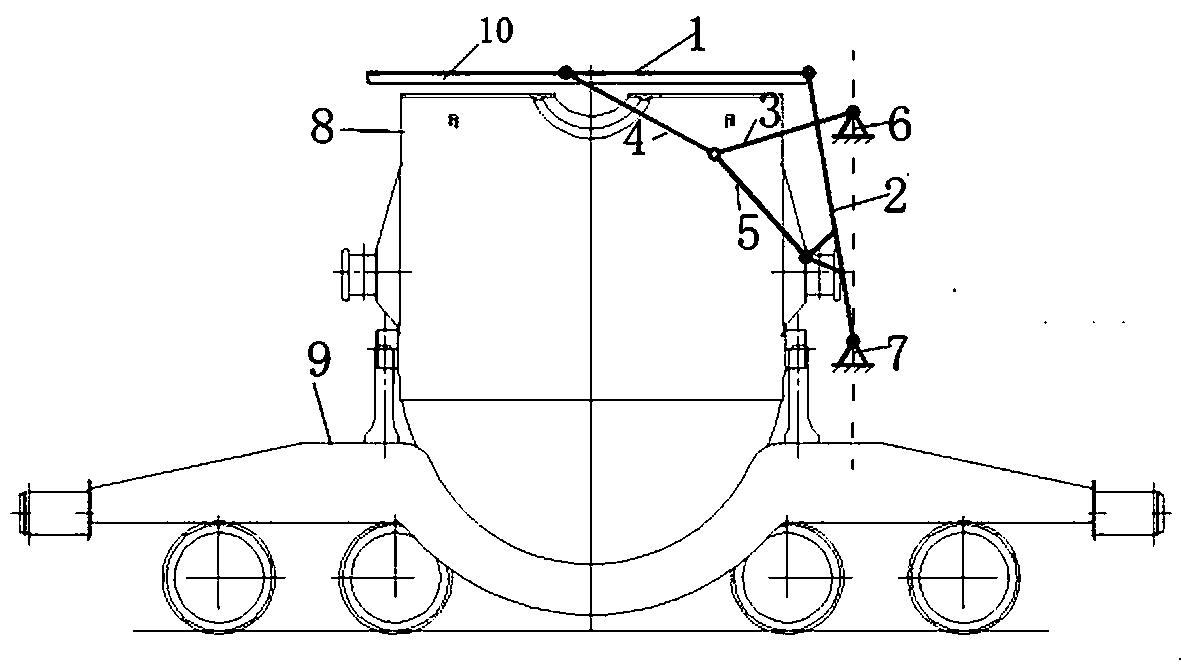

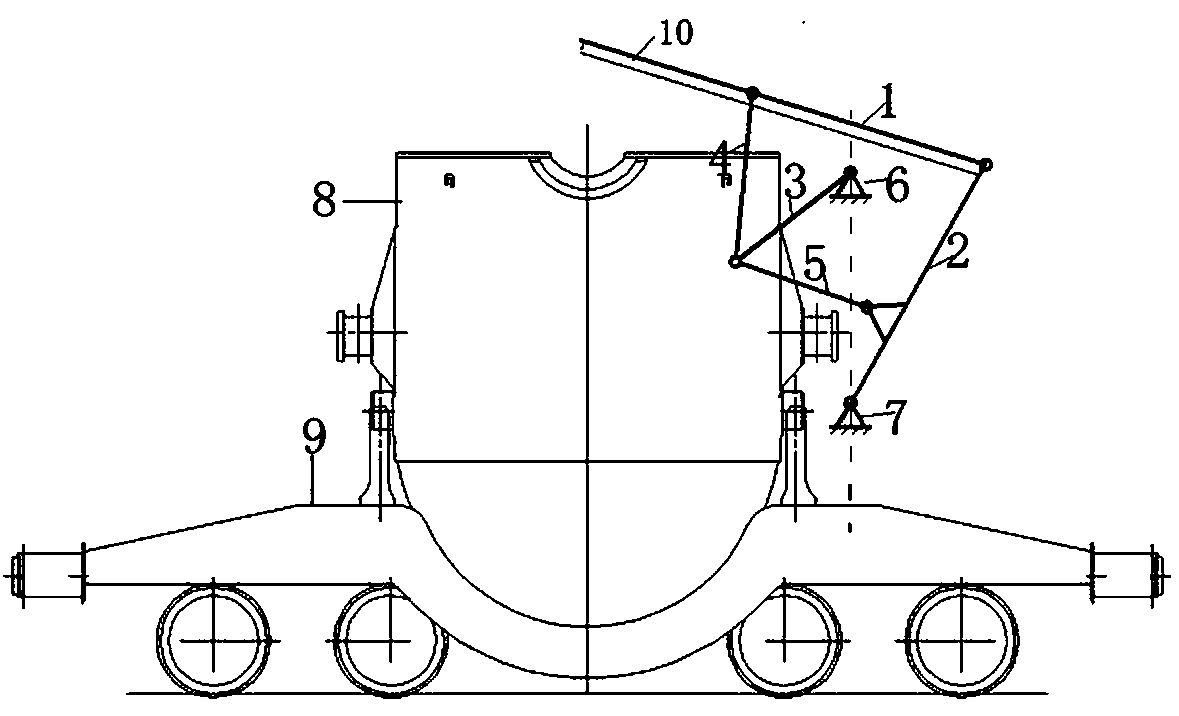

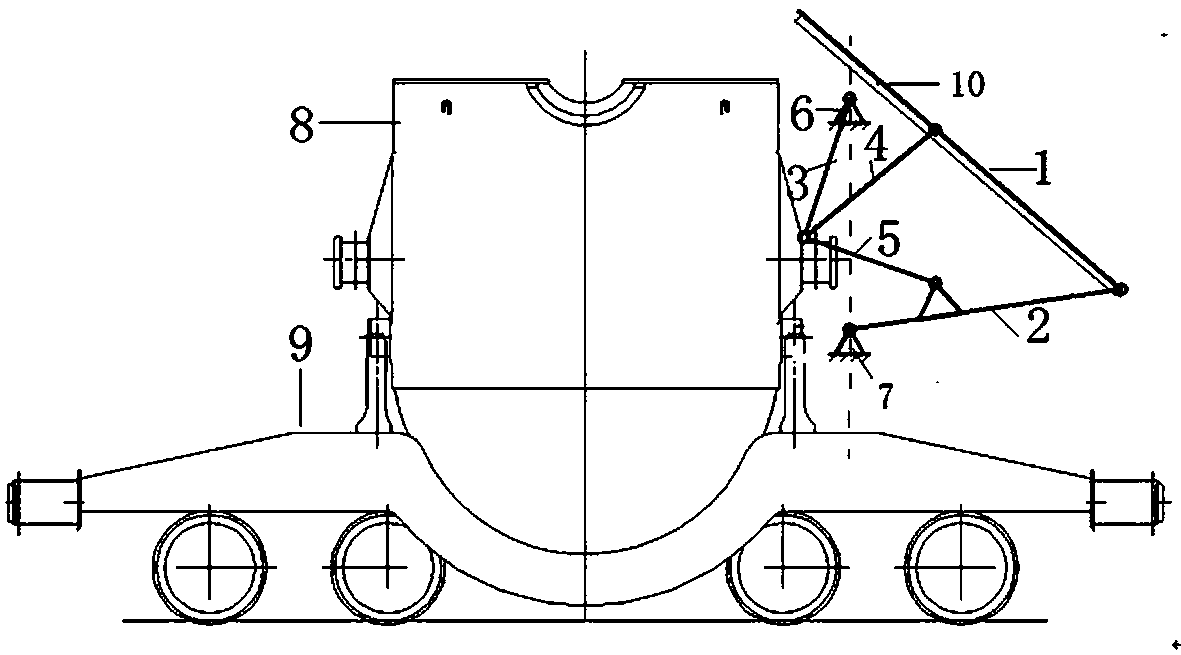

[0018] figure 1 As shown, the insulation cover is closed on the molten iron tank. Hot metal tank 8 is located on the hot metal car 9. Both sides of the heat preservation cover 10 are respectively fixedly connected with a set of six-bar linkage, and the six-bar linkage structure is supported by the upper fixed hinge point 6 and the lower fixed hinge point 7 positioned next to the upper molten iron tank 8 of the molten iron car 9 . The six-link structure is composed of a cover connecting rod 1, an upper driving rod 3, a lower driving rod 2, an upper driven rod 3 and a lower driven rod 5. One end of the lower active rod 2 is hinged with the lower fixed hinge point 7, and the other end is hinged with the cover connecting rod 1 by the hinge at the edge end of the heat preservation cover 10. One end of the upper driving rod 3 is hinged with the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com