Polishing device with double polishing wheels capable of being easily disassembled and assembled

A technology of polishing device and polishing wheel, which is applied in the field of polishing, can solve problems such as potential safety hazards and inconvenient disassembly, and achieve the effect of high safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

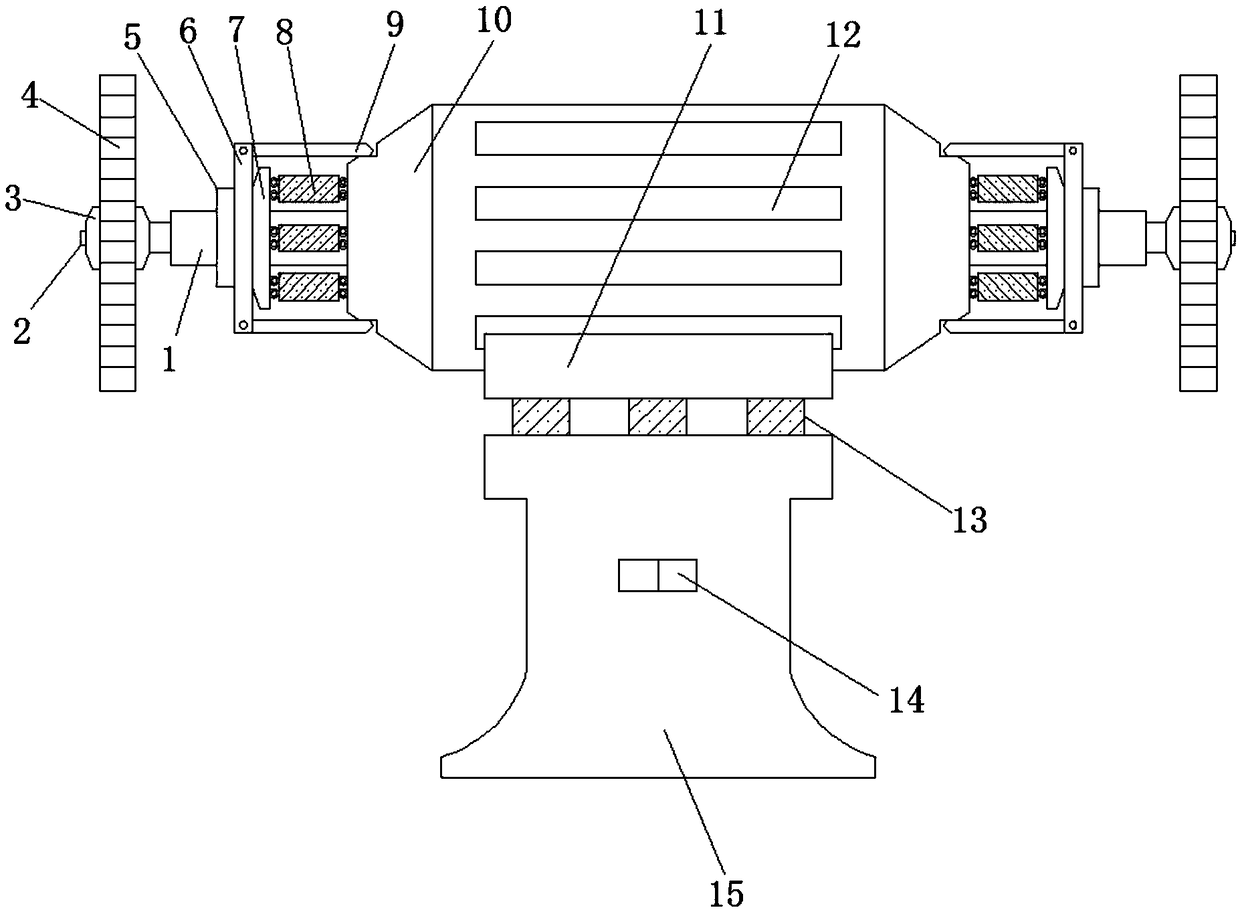

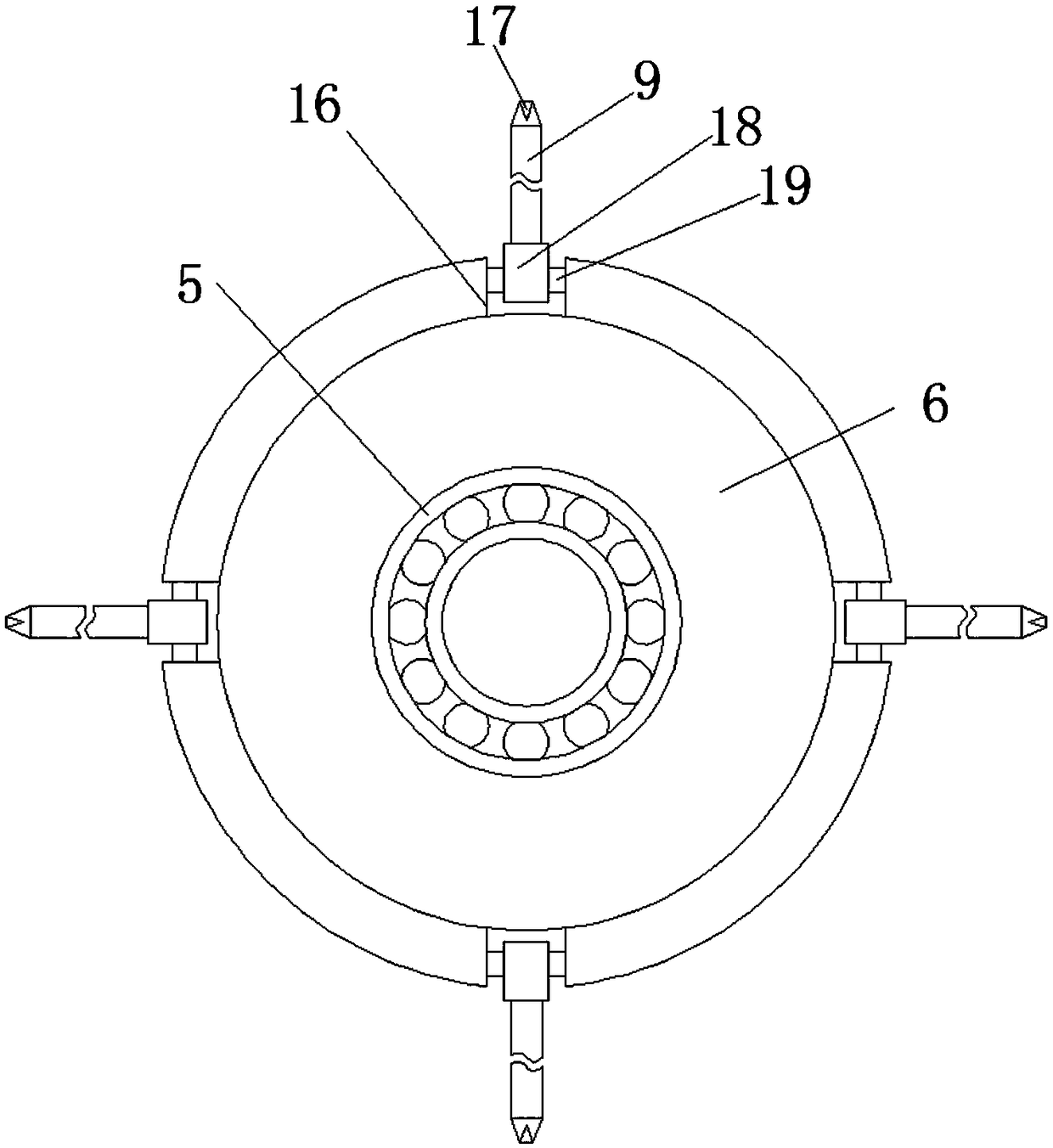

[0020] Embodiment one, with reference to Figure 1-4 , a polishing device that is easy to disassemble and has double polishing wheels, it includes a biaxial motor 12, a support plate 11 is welded below the biaxial motor 12, a base 15 is arranged below the support plate 11, the base 15 and the support plate 11 They are connected by a vertical rod 13, and the front surface of the base 15 is embedded with a rocker switch 14 for controlling the biaxial motor 12. An output shaft 24 is arranged at the center of the two ends of the biaxial motor 12, and the outer walls of the two ends of the biaxial motor 12 are welded. There is a card cover 10, one side of the card cover 10 is connected with a mounting plate 7 through a return spring 8, a bearing plate 5 is embedded in the center of the mounting plate 7, a polishing shaft 1 is sleeved inside the bearing plate 5, and one end of the polishing shaft 1 A polishing wheel 4 is fixed through the positioning plate 3, and the other end of th...

Embodiment 2

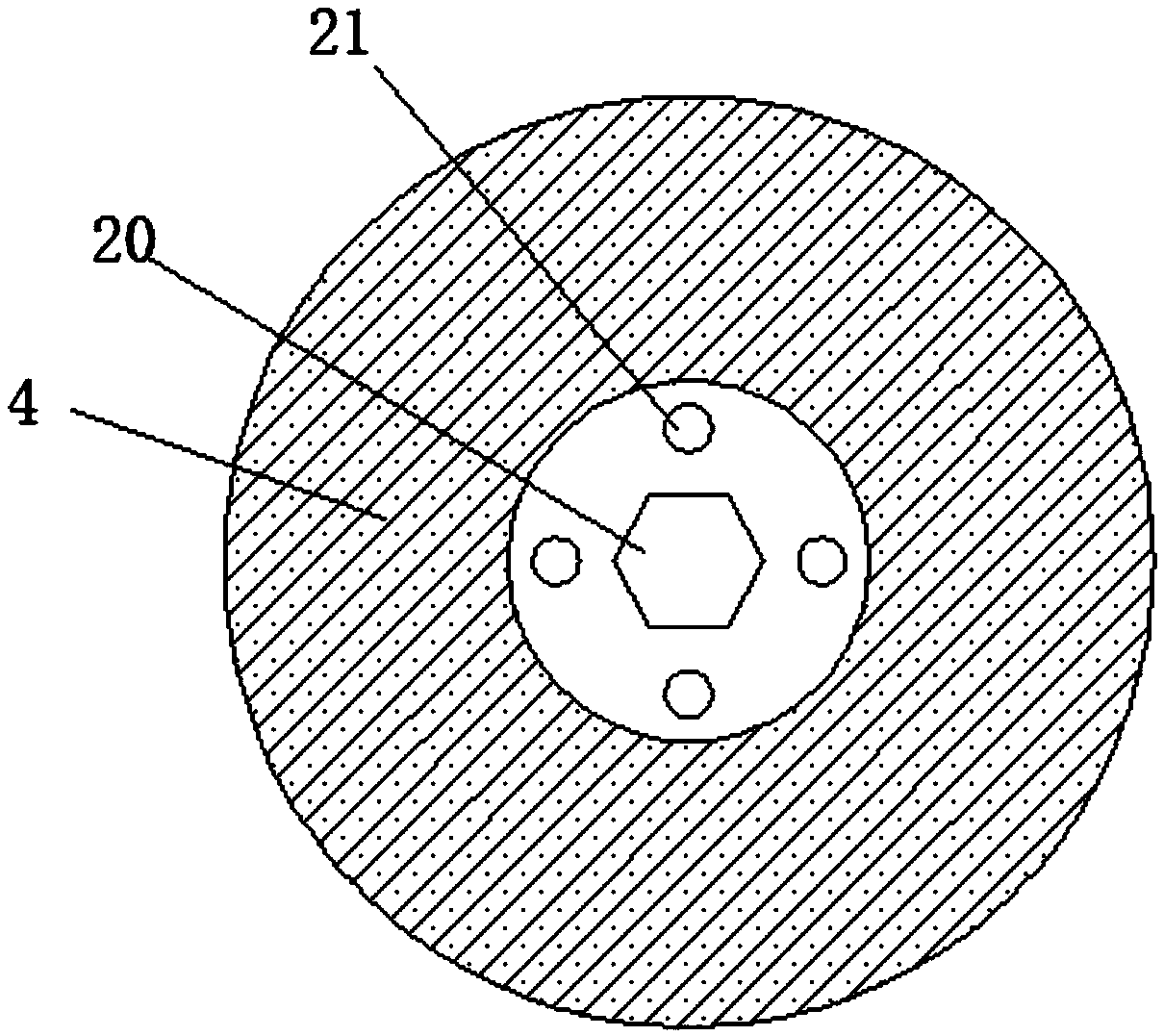

[0021] Embodiment two, refer to figure 1 , image 3 and Figure 4 , the center of the positioning plate 3 is fixed on one end of the polishing shaft 1 through the connecting bolt 2, and the center of the polishing wheel 4 is provided with a clamping hole 20 for passing through the polishing shaft 1, and the clamping hole 20 is a regular hexagonal structure, and the polishing shaft 1 is external The port at one end has a regular hexagonal structure, and the surface of the polishing wheel 4 is located on the outside of the clamping hole 20. Four alignment holes 21 are equidistantly arranged on the outside of the card hole 20. The alignment of the four alignment holes 21 can make the installation of the polishing wheel more accurate and convenient. , and the stability is higher after installation.

Embodiment 3

[0022] Embodiment three, refer to figure 1 and Figure 4 , one end of the output shaft 24 is welded with a clamping shaft 23, and the clamping shaft 23 is a regular triangular prism structure, and one end of the polishing shaft 1 is provided with a socket 22 for inserting the clamping shaft 23, so that the clamping shaft 23 and the polishing shaft 1 can be connected according to needs. It is combined or separated so that the two polishing wheels 4 can work independently.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com