A Method for Installing Rapid Prototype on Automobile Clay Model

A clay model, fast technology, applied to teaching models, fixtures, instruments, etc., can solve the problems of inaccurate disassembly and positioning, cumbersome installation and removal procedures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0059] Example 1, the installation of a quick sample of the front cover grille of a 1:1 sludge model of a medium-sized car:

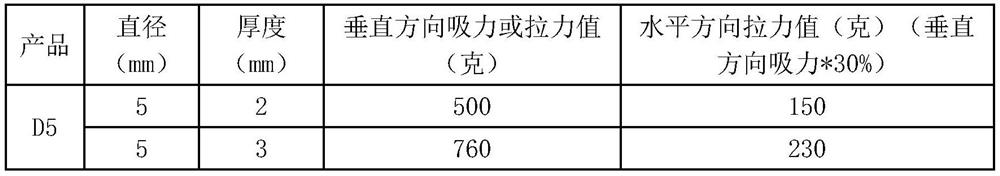

[0060] Weigh it with an electronic scale. The weight of the front grille quick sample is 2200g. According to the weight of the 2200g front grille quick sample, referring to the horizontal tension value in Table 1, it is estimated that 4 pieces of 16mm diameter and thickness are required. For the 3mm target magnet group.

example 2

[0061] Example 2, quick sample installation of the outer panel of the front wall of a heavy engineering vehicle 1:1 sludge model:

[0062] Weigh it with an electronic scale. The weight of the quick sample of the outer side panel of the dash is 1016 grams. According to the weight of the quick sample of the 1016 grams of the outer side panel of the dash, it is estimated that 2 pieces of 10mm in diameter and 10 mm in thickness are required with reference to the horizontal tensile force value in Table 1. For the 3mm target magnet group.

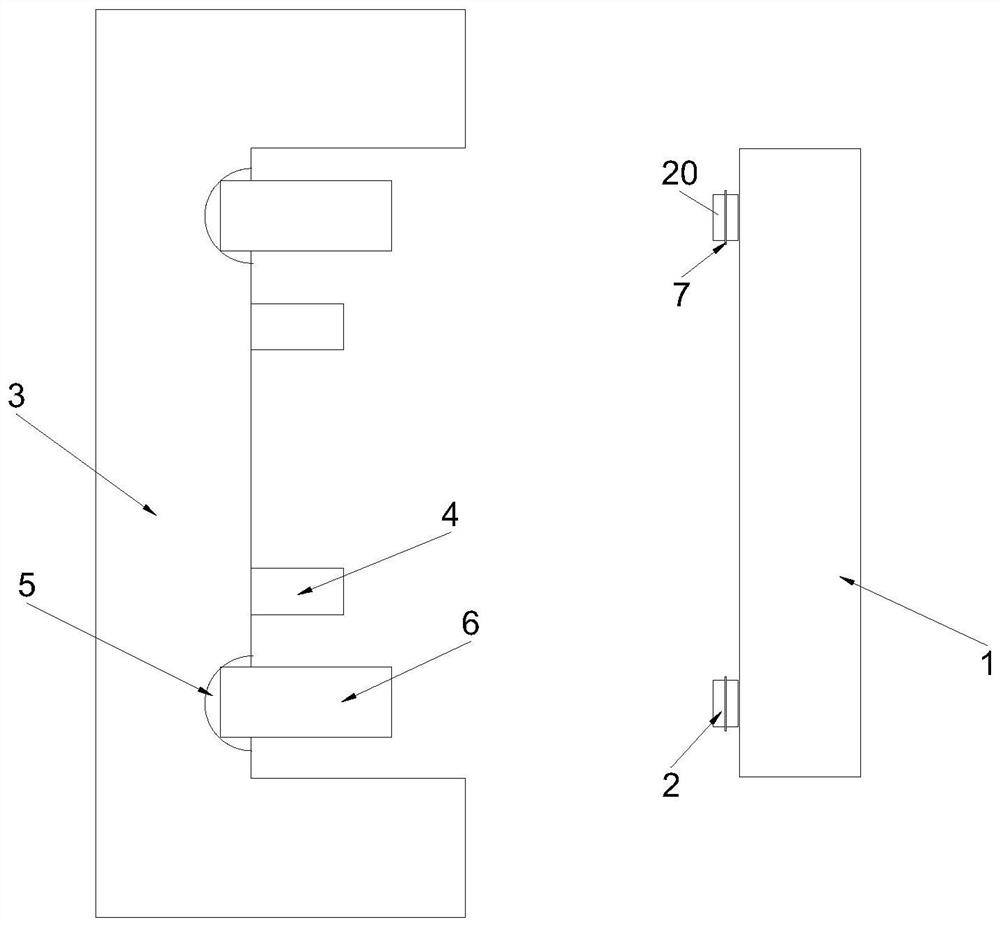

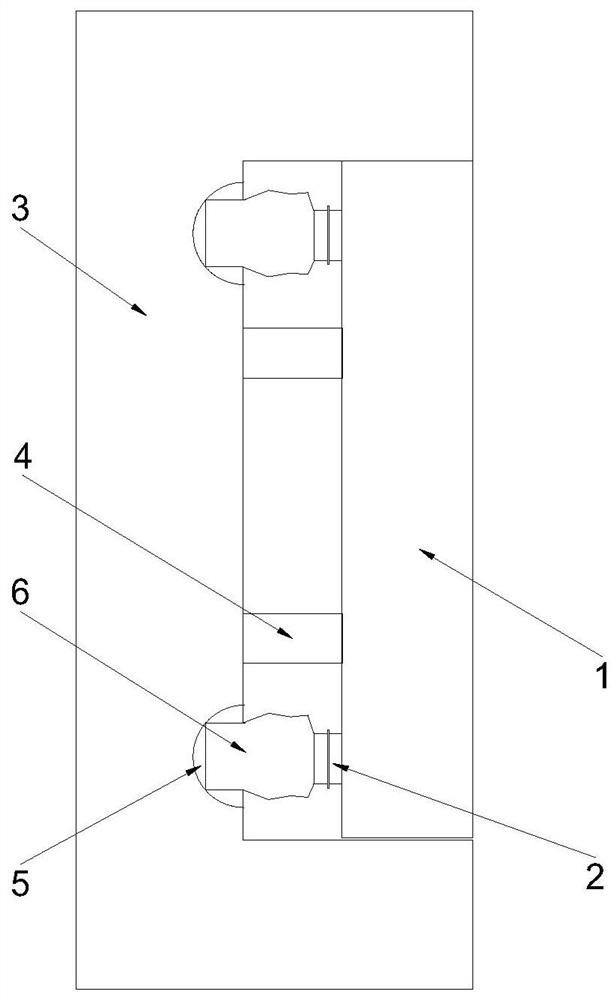

[0063] S4: Fix a magnet 20 in the target magnet group 2 on the quick sample 1, and determine the corresponding position of the magnet 20 on the clay model 3;

[0064] Select a position suitable for fixing the magnet 20 according to the shape of the back of the quick sample 1, and mark it, and then fix the magnet 20 at the marked position by super glue.

[0065] The corresponding position of the magnet 20 on the clay model 3 is determined accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com