Discharging system for mechanical equipment

A mechanical equipment and material cutting technology, which is applied in the direction of unloading devices, clay preparation devices, chemical instruments and methods, etc., can solve problems such as easy solidification in the feeding port, inconvenient material dredging, and affecting the normal operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

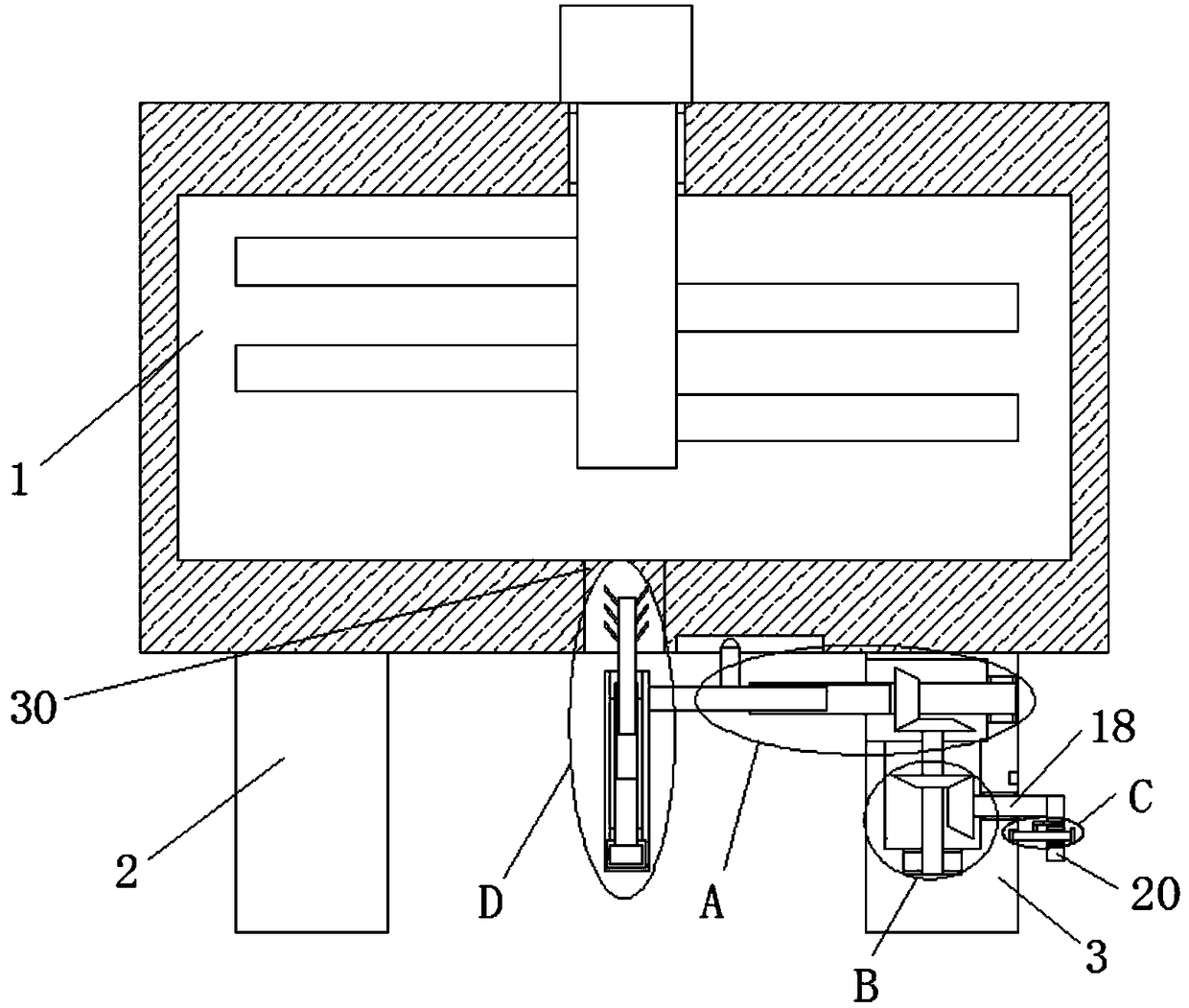

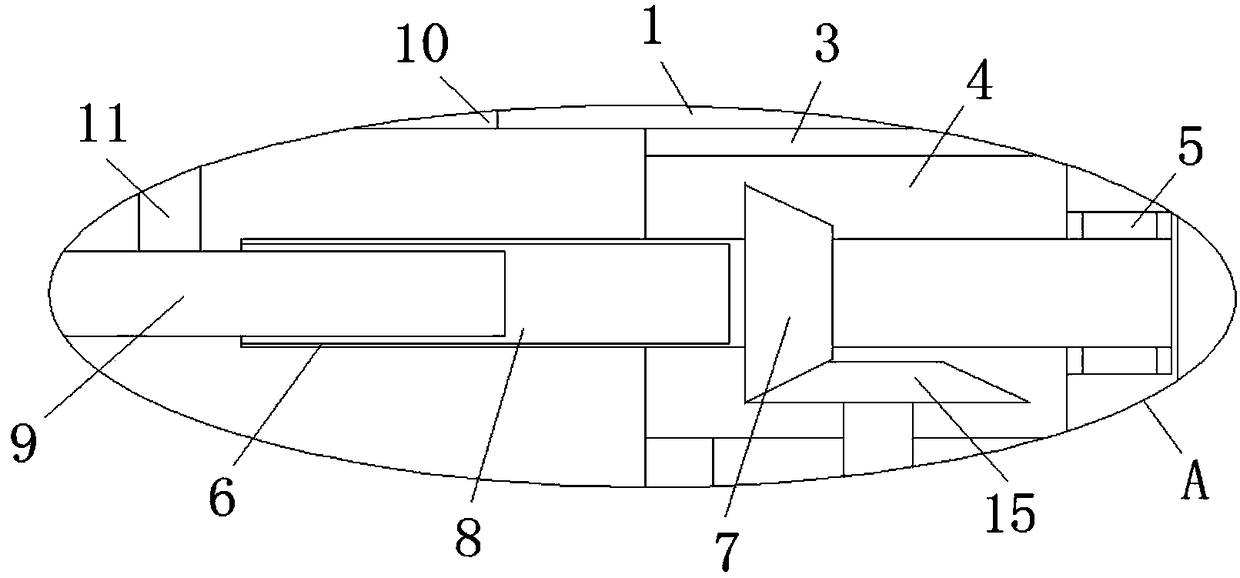

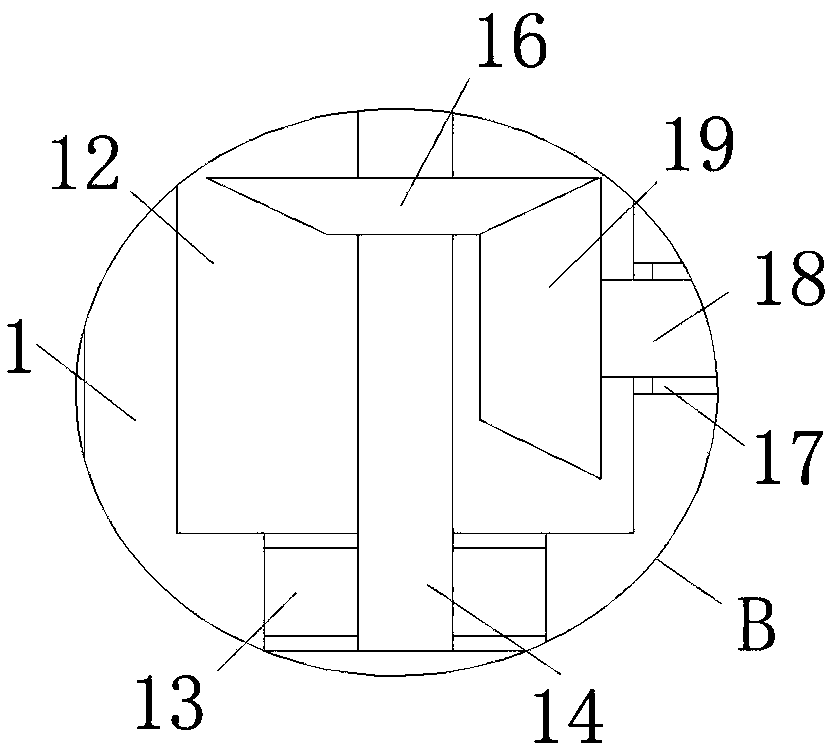

[0026] refer to Figure 1-5In this embodiment, a cutting system for mechanical equipment is proposed, including a mixer 1, a first support column 2 and a second support column 3 are fixedly installed at the bottom of the mixer 1, and the second support column 3 is close to the first support One side of the column 2 is provided with a limiting groove 4, and a first rotating groove 5 is provided on the inner wall of one side of the limiting groove 4, and the same rotating column 6 is installed in the first rotating groove 5 and the limiting groove 4 for rotation. The outer fixed sleeve of the column 6 is provided with a first bevel gear 7, and the end of the rotating column 6 close to the first support column 2 is provided with a first threaded groove 8, and the first threaded groove 8 is internally threaded with a first screw rod 9 , the bottom of the mixer 1 is provided with a first chute 10, the top of the first screw 9 is fixedly installed with a first slider 11, and the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com