Lime pretreatment storage tank

A pretreatment, lime technology, applied in clay preparation devices, chemical instruments and methods, cement mixing devices, etc., can solve the problems of lime deterioration calcium oxide, not more than one day, lime deterioration, etc., to increase the internal temperature, not easy to accumulate into Block, not easy to spoil the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in detail, but it should be understood that protection scope of the present invention is not limited by specific embodiment.

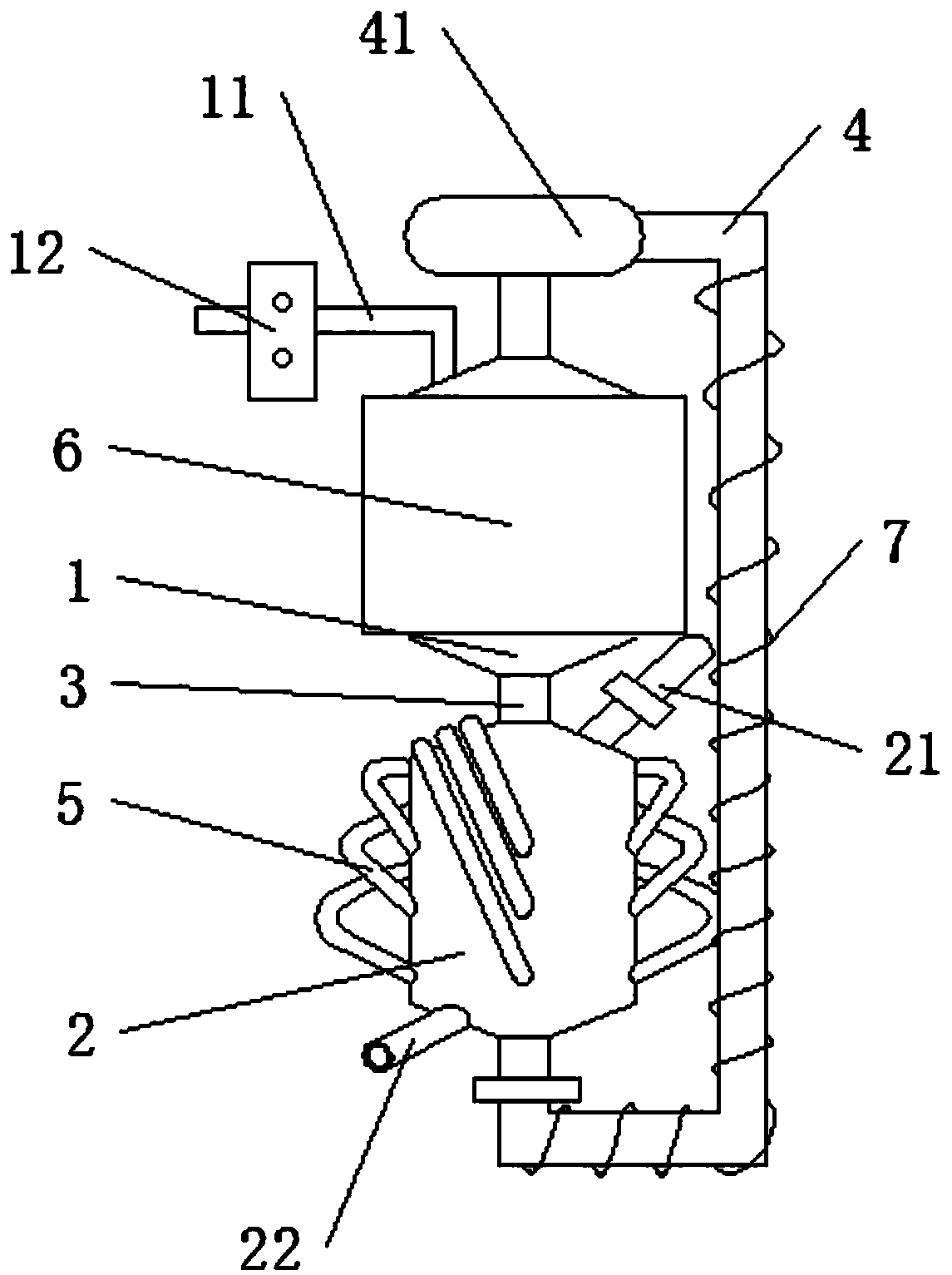

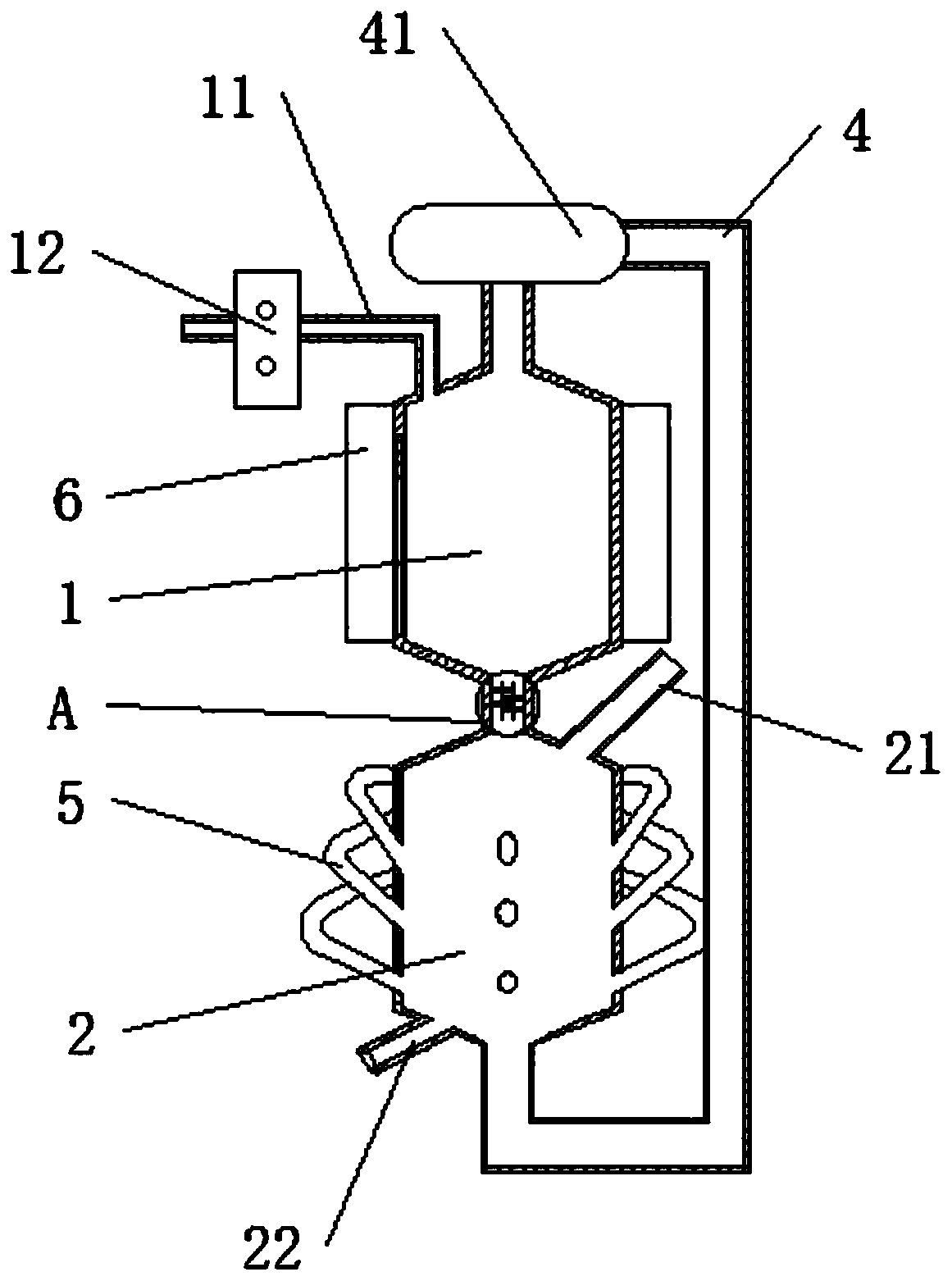

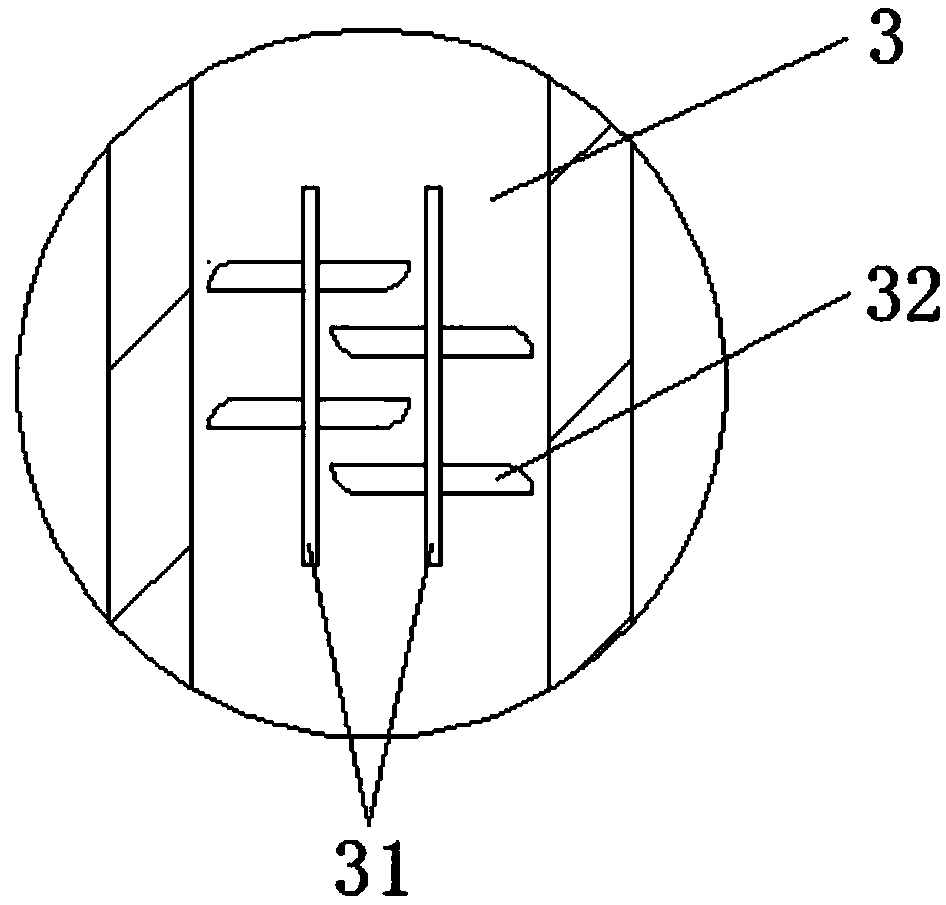

[0021] Embodiments of the present invention are as follows: Figure 1~3 As shown, a lime pretreatment storage tank includes a first tank body 1 and a second tank body 2 arranged up and down, the first tank body 1 and the second tank body 2 are connected by a first pipeline 3, and the first pipeline 3 is provided with a stirring mechanism for breaking up block lime, and the second tank body 2 is also communicated with the first tank body 1 through the second pipeline 4, and the second pipeline 4 is provided with the lime that can put the lime in the second tank body 2 The vacuum pump 41 pumped into the first tank body 1, the side wall of the second tank body 2 is provided with a blowing duct 5 capable of blowing inert gas, the first tank body...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap