A glass panel integrated processing device and processing method thereof

A glass panel and processing device technology, which is applied to stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of poor quality, easy shaking or sliding, and dust in the processing of glass panels, and achieves accurate processing position, The effect of improving processing quality and high processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

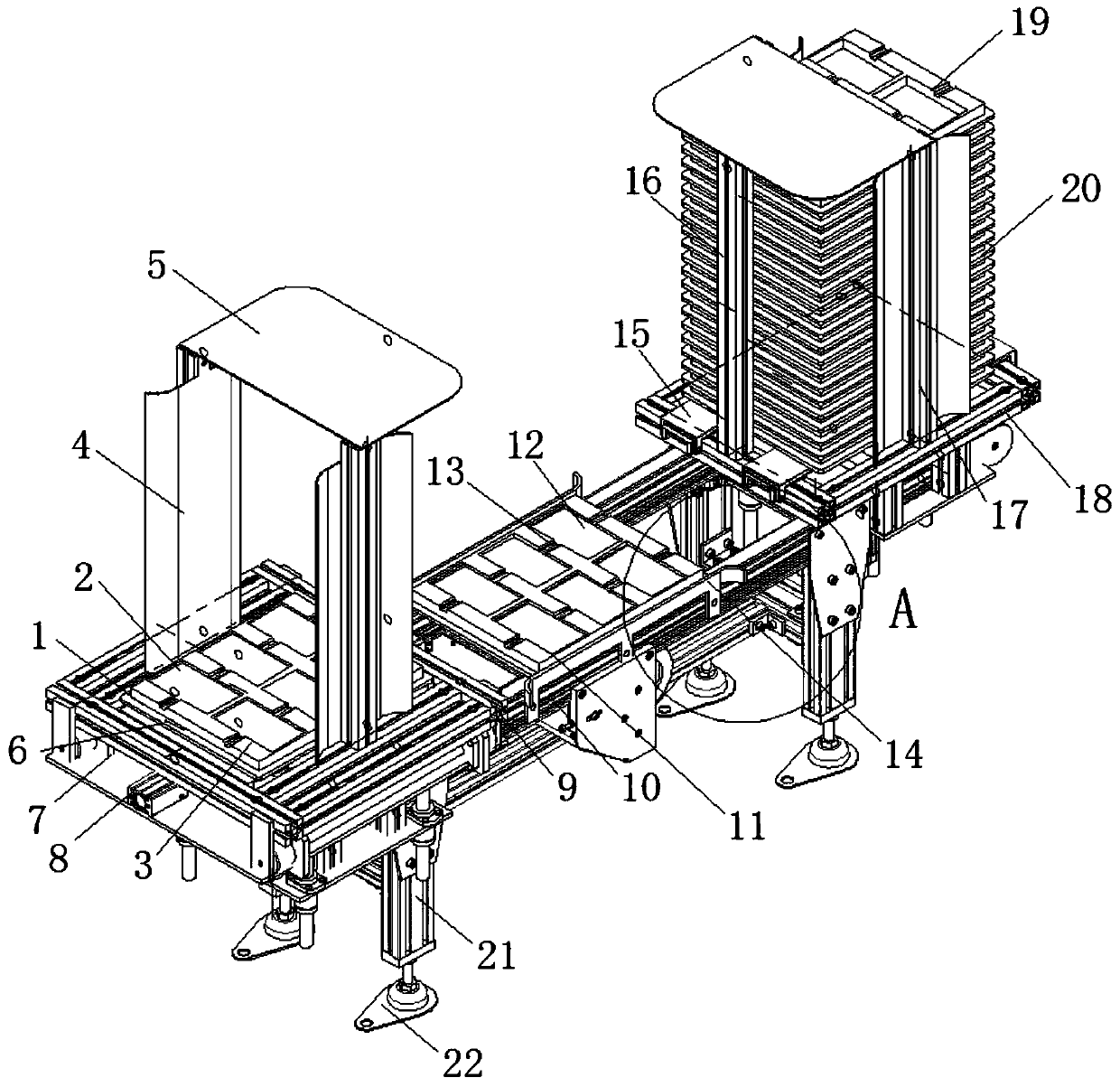

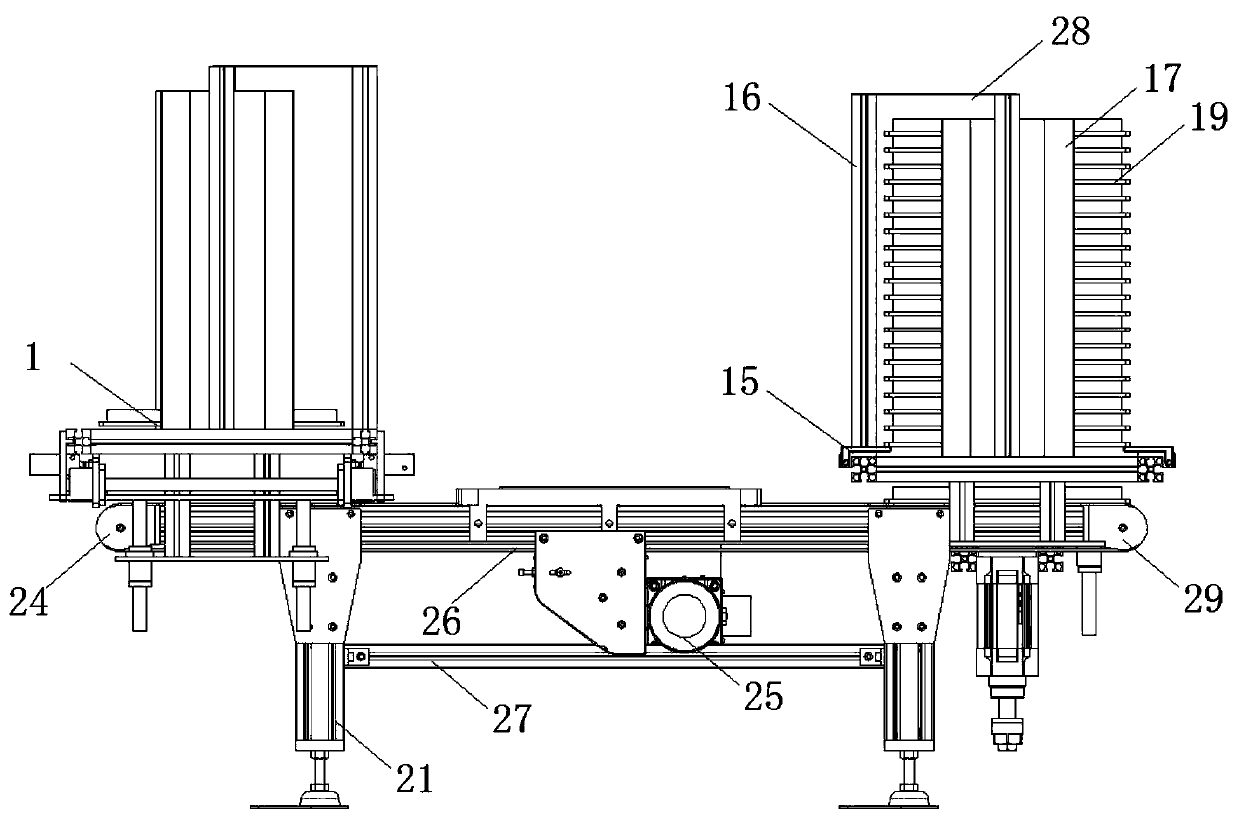

[0032] see Figure 1-6 As shown, a glass panel integrated processing device includes a cutting area 1, an engraving area 11 and a loading area 19. The cutting area 1 is provided with several loading slots 2 at equal intervals, and the two ends of the several loading slots 2 are provided with convenient Cutting sheet 3 for glass panel cutting;

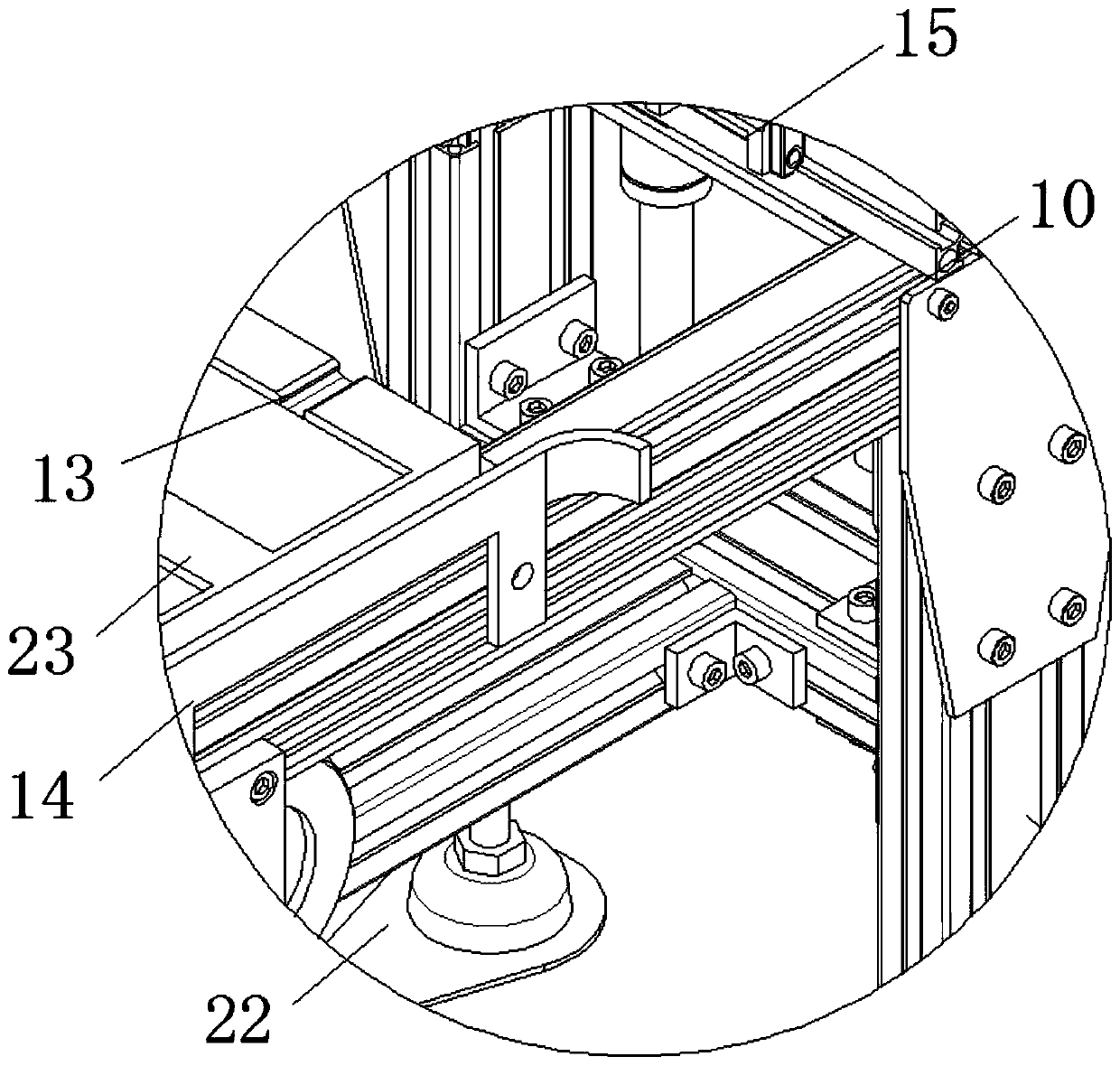

[0033] Wherein, vertical baffles 4 are longitudinally arranged at both ends of the cutting area 1, and horizontal baffles 5 are vertically welded above the two longitudinal baffles 4, filter plates 6 are arranged at the bottom of the cutting area 1, and both ends of the cutting area 1 Both are provided with a first slide frame 9, and a first slide rail 10 is provided through the interior of the two first slide frames 9, and a dust bucket 7 is provided under the filter plate 6, and a dust bucket 7 is provided under the cutting area 1, which is connected with the first slide frame 9. Matched first motor 24, one end of the first motor 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com