Drive axLe rear axLe appLicabLe to heavy trucks

A technology for trucks and rear axles, applied in the directions of axles, wheels, brakes, etc., can solve the problems of large number of parts, heavy weight and high manufacturing cost, and achieve the effects of reducing weight, improving stability and improving connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

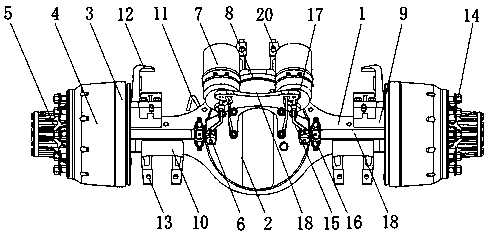

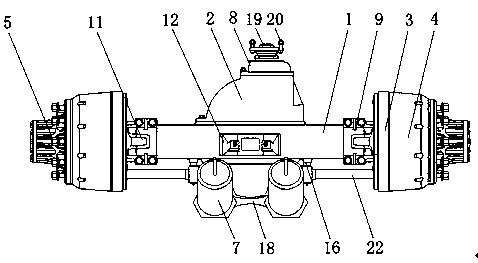

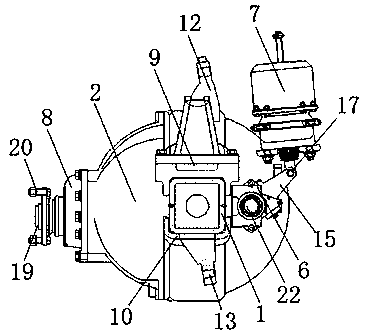

[0016] The present invention will be described in more detail below in conjunction with the accompanying drawings.

[0017] as attached Figure 1-4 As shown, a drive axle rear axle suitable for heavy-duty trucks includes an axle body 1, an axle housing 2, a half shaft 3, a brake assembly 4, a hub 5, a fixed block 6, an air chamber 7 and a reducer assembly 8. It is characterized in that: the two ends of the bridge body 1 are respectively provided with an upper leaf spring seat 9 and a lower leaf spring seat 10, a trachea support 11 is arranged in the middle of the bridge body 1, and a The upper bracket 12 improves the stability of the air pipe on the rear axle of the drive axle through the air pipe support 11, avoids damage to the air pipe, and improves the integrity of the air pipe. The upper support 12 improves the position accuracy of the installation of the rear axle of the drive axle and enhances driving For the stability of the rear axle after installation, the axle hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com