Real silk wool composite filament and preparation method thereof

A composite silk and wool technology, applied in silk fiber production, yarn, textiles and papermaking, etc., can solve the problems of strand straightening, broken end, silk wrinkle, etc., achieve the effect of firm bonding and reduce spinning cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

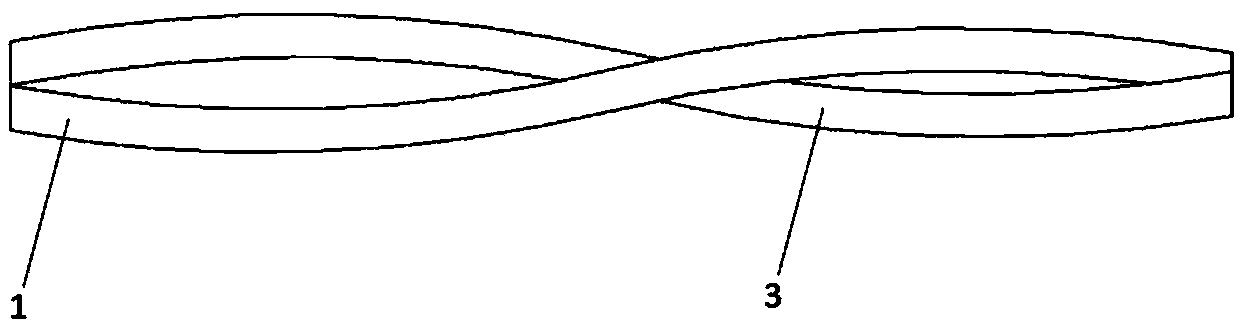

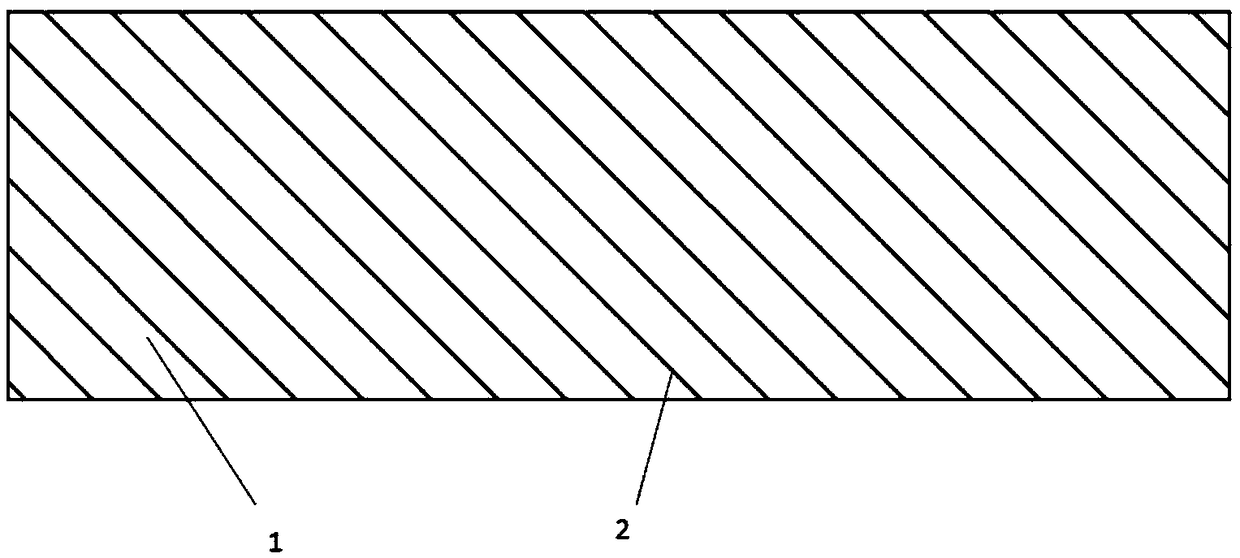

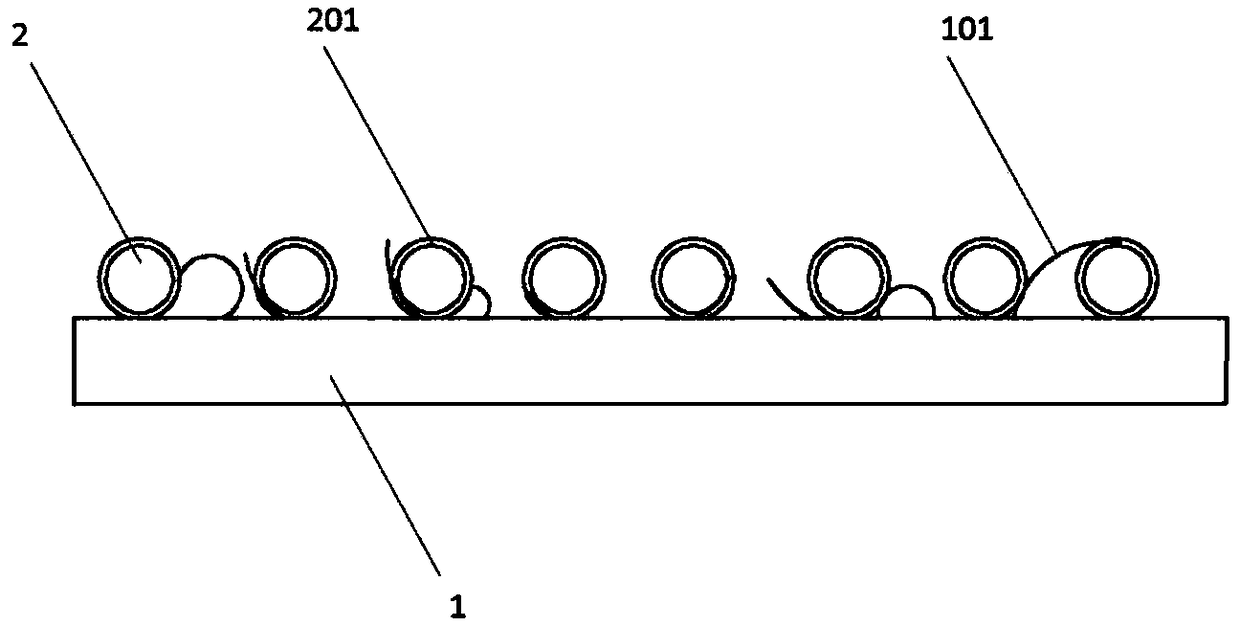

[0029] A silk wool composite silk such as figure 2 As shown, it includes: wool yarn 1 with the center core arranged in a straight line or approximately straight line. 8 or 16 or 18 or 32 or other number of cocoon threads 2 are bonded and wrapped on the outer wall of the wool yarn 1 . The amount of the cocoon silk 2 depends on the necessary amount for wrapping the cocoon silk 2 on the outer wall of the wool yarn 1 . The threads of the cocoon threads 2 have the same direction and are parallel to each other, and the content of the cocoon threads 2 in the composite thread is 30%. After research, the applicant found that the silk-wool composite yarn prepared with this structure needs to strictly control the content of cocoon silk 2 in the range of 25%-40%, otherwise the comprehensive performance of the composite yarn will easily decrease. In addition, compared with the existing structure, the composite yarn with this structure has a tighter distribution of the cocoon filaments o...

Embodiment 2

[0038] Based on the silk-wool composite yarn described in Example 1, the qualified raw material cocoon in step S1 is: the unwinding rate is greater than 70%, the number of hangings per 10,000 meters is less than 2.5 times, and the cocoon width uniformity rate is greater than 75%. Using the raw material cocoons of this standard can obtain high-quality silk-wool composite yarns, reduce the problem of cocoon thread breakage during the preparation process, and stabilize the thickness of silk-wool composite yarns.

Embodiment 3

[0040] Based on the silk-wool composite yarn described in Example 1, when the threading operation described in step S3 is performed, the operating temperature is controlled to be 94°C. When carrying out the arranging operation described in step S3, the operating temperature is controlled to be 42°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap