Manufacturing method of prestressed plate components manufactured by adopting cross-laminated timbers

A technology of plywood and production method, which is applied to building components, floor slabs, bridge parts, etc., can solve the problems of limited application of prestress and loss of prestress, and achieve the effects of small cross-section, light weight and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

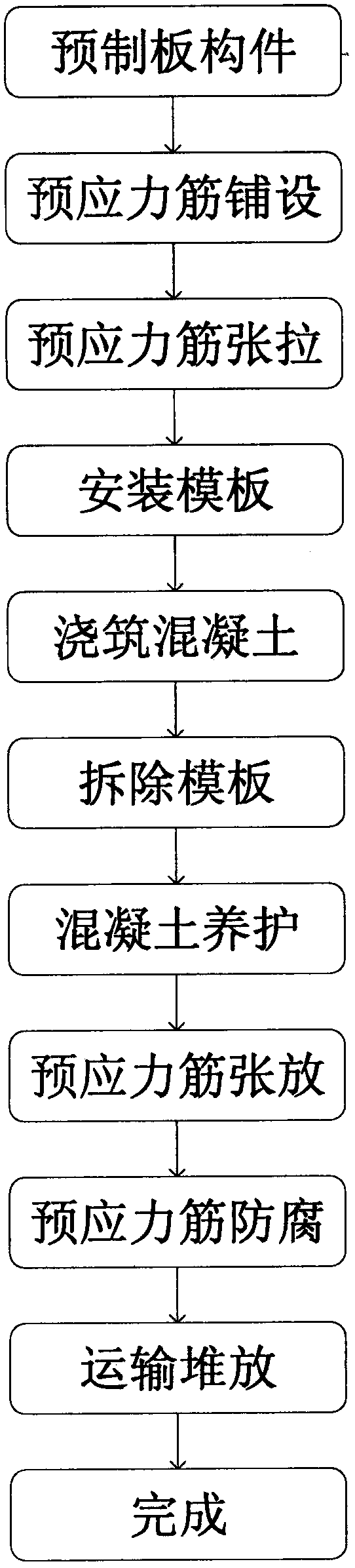

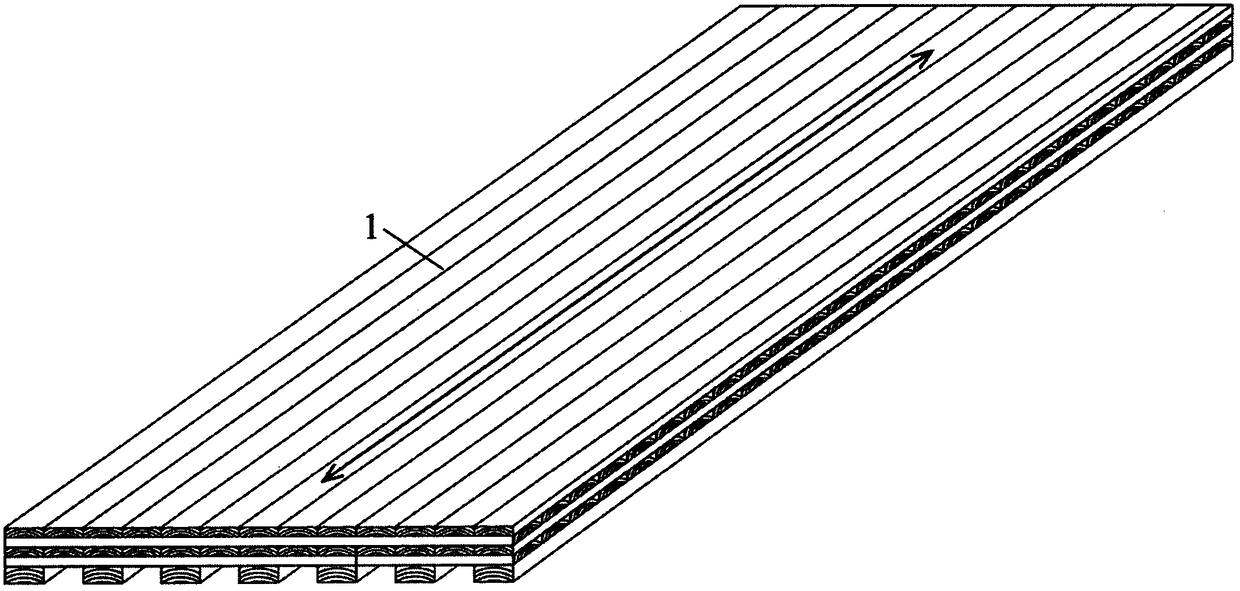

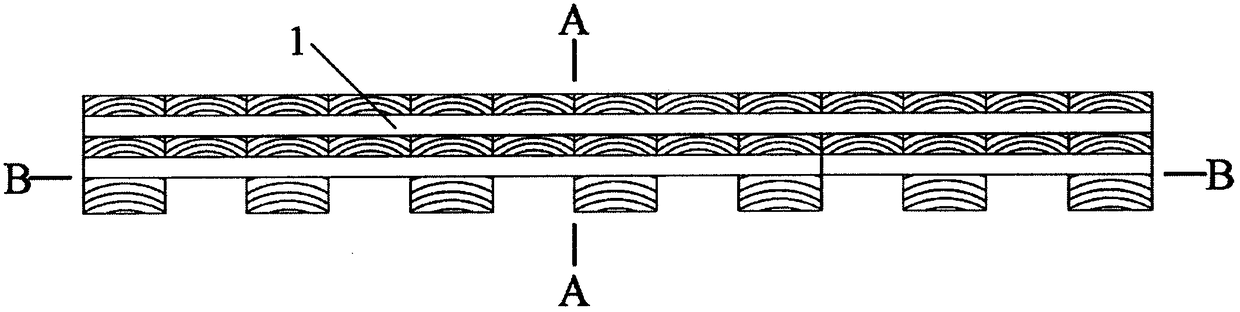

[0038] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Such as figure 1 As shown, a method for making prestressed slab components made of cross-glued wood is characterized in that the prestressed tendons 3 are located in the geometric space formed after one side of the outermost layer of the prefabricated cross-glued wood 1 is drawn out, After the tensioning of the prestressed tendons 3 is completed, the end formwork is installed at the end of the geometric space formed after one side of the outermost layer of the prefabricated cross-glued wood panel 1 is drawn out, and then the concrete 2 is poured and vibrated and leveled. When the concrete 2 When the strength is greater than or equal to 2.5MPa, the end formwork is removed, the concrete 2 is cured until the strength is not less than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com