PLasterboard cracking resistance mechanism

A gypsum board and hanging board technology, which is applied to building components, building structures, buildings, etc., can solve the problems of owners' economic consumption and easy cracking, and achieve the effects of good work performance, enhanced support effect, and simple design structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

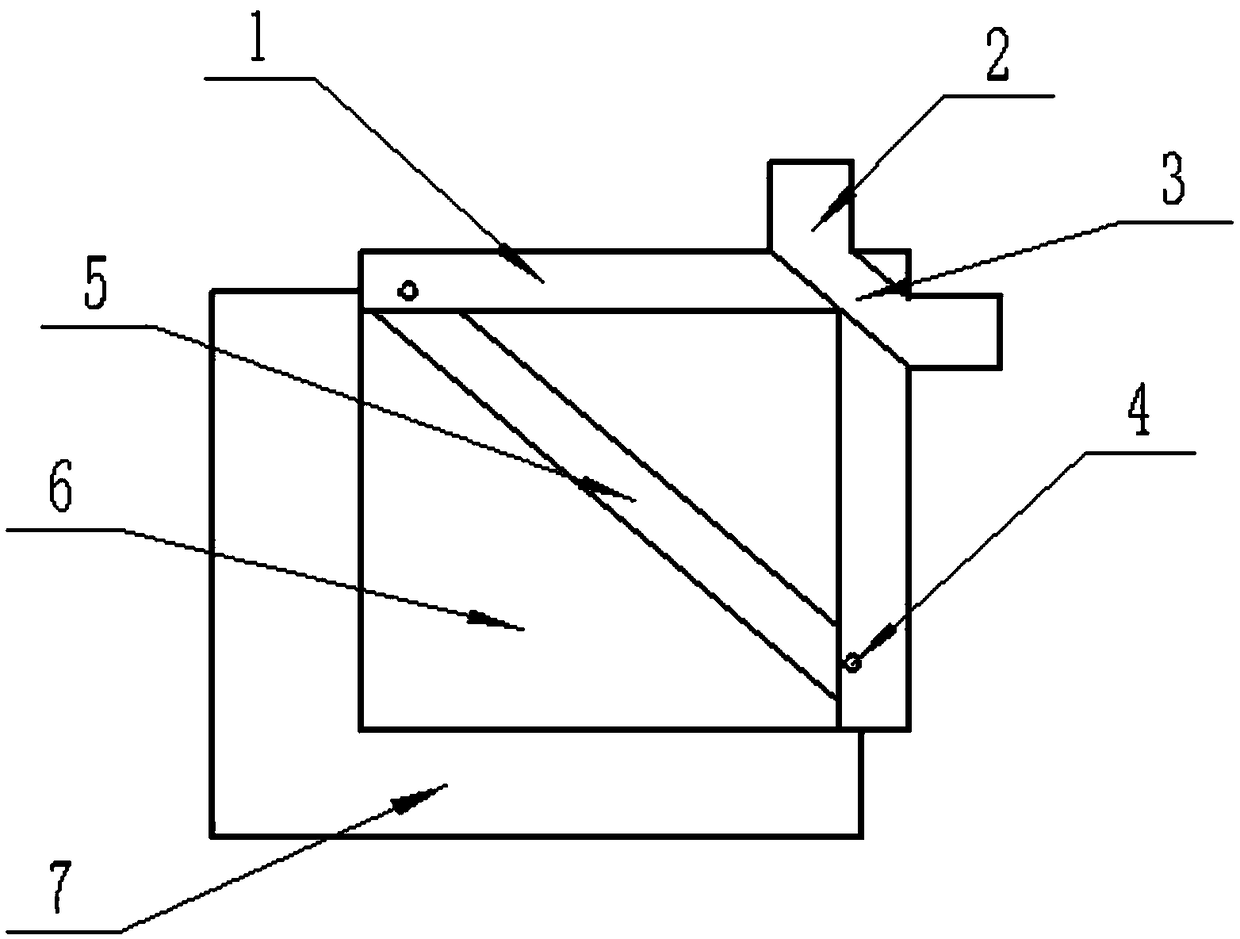

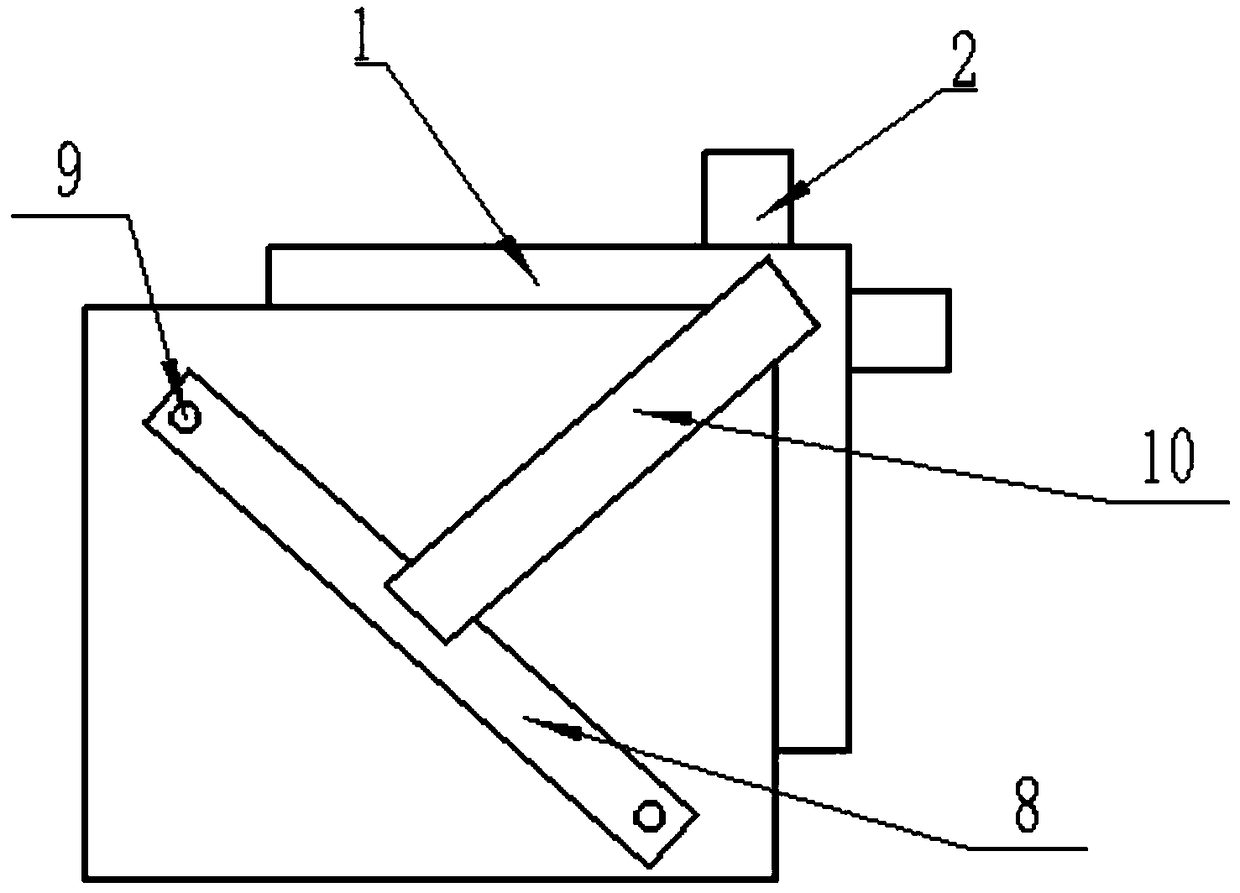

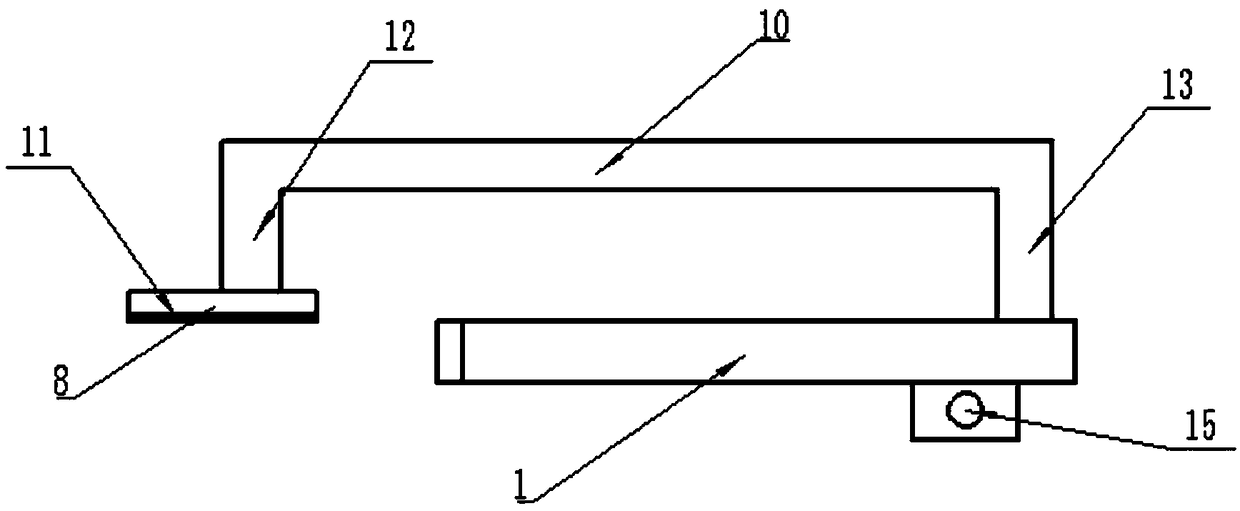

[0016] see Figure 1-4 , a plasterboard cracking prevention mechanism, including a connecting device and a hanging board device; the connecting device is provided with an L-shaped edge guard 1, a clamping groove 14, a plasterboard 7, a common square plate 6, a supporting steel plate 5, a first screw Holes 4, wall blocks 2, connecting blocks 3 and bolt holes 15; the L-shaped edge guard 1 is arranged on the right side of the connection device, and the L-shaped edge guard 1 is placed at the corner of the wall for connecting the plasterboard 7. The clamping groove 14 is arranged on the two side plates of the L-shaped edge guard 1, and the clamping groove 14 is used to clamp the two side edges of the gypsum board 7 at the corner of the suspended ceiling; the notch width of the clamping groove 14 is greater than the thickness of the gypsum board 7, it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com