Fixed tool for detecting wind power blade

A technology for fixing tooling and wind turbine blades, applied in the direction of measuring devices, measuring instrument components, instruments, etc., can solve the problems of lack of devices, achieve accurate calibration, expand the detection coverage, and save the effect of manual displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

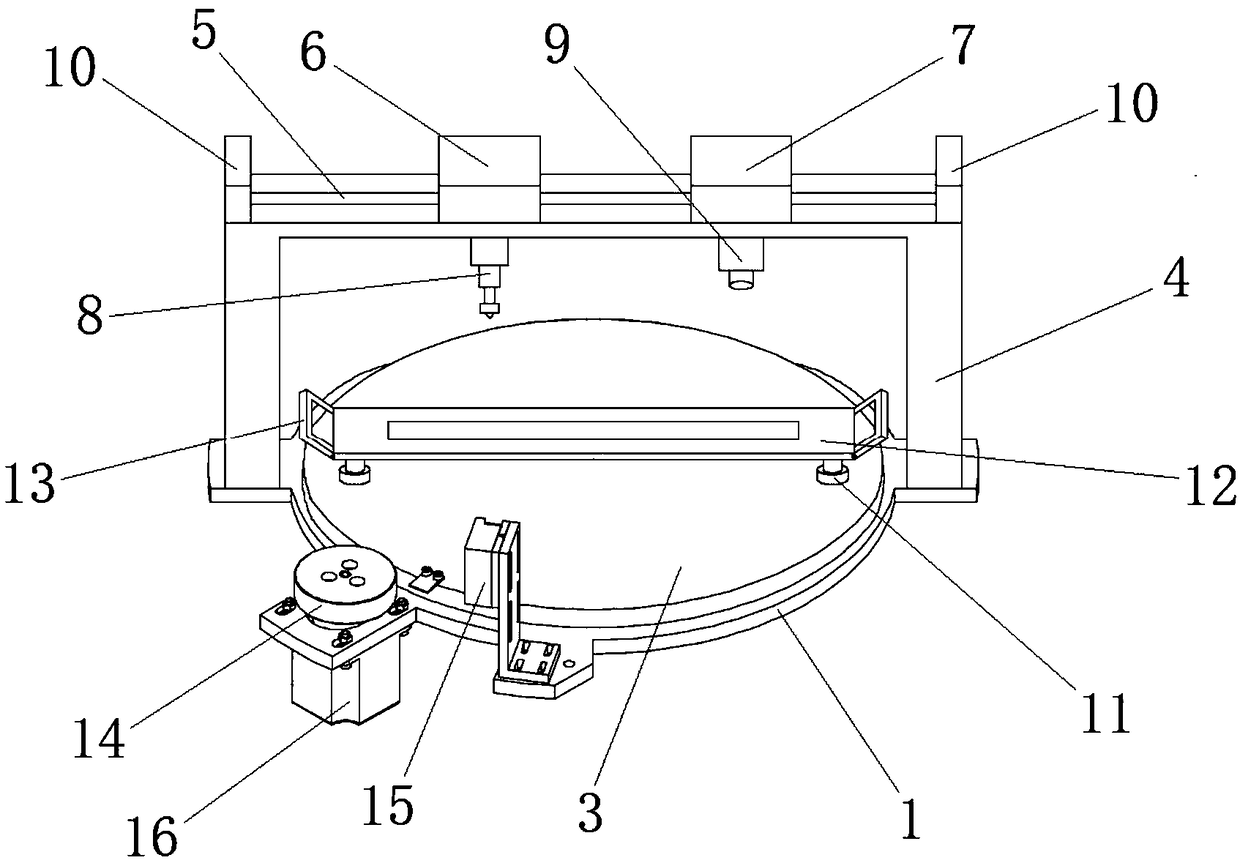

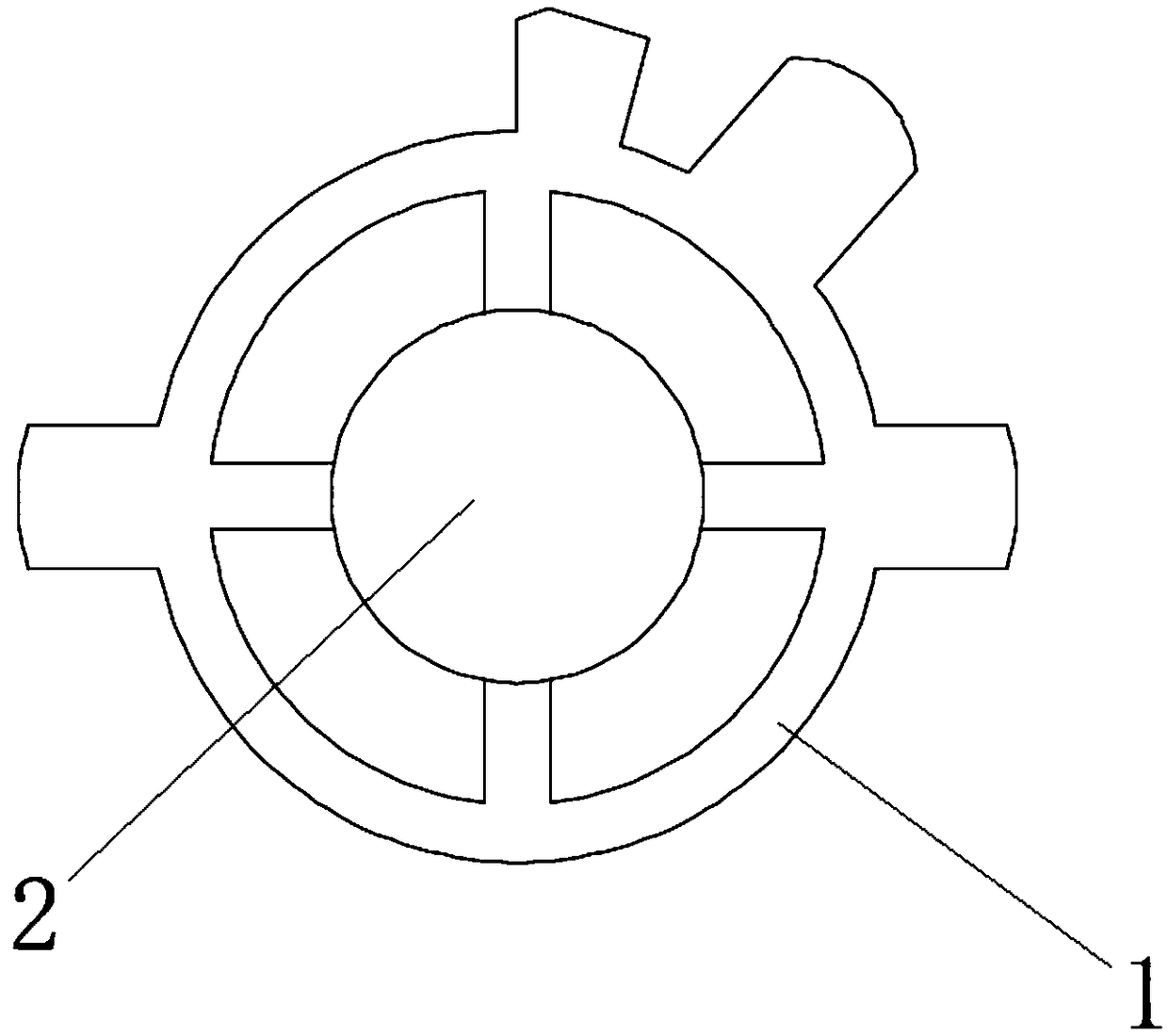

[0024] A fixed tooling for wind turbine blade inspection, such as figure 1 , figure 2 As shown, it includes a fixed plate 1, a central axis 2, a turntable 3, a pillar 4, a slide rail 5, a first slider 6, a second slider 7, a first detector 8, a second detector 9, and a baffle 10. Hydraulic cylinder 11, bracket 12, snap ring 13, gear 14, third detector 15, motor 16, wherein fixed disk 1 is connected with central axis 2, turntable 3 is fixedly connected with said central axis 2, and pillar 4 has 2 The two pillars 4 are respectively vertically fixedly connected to the edge of the fixed plate 1, the two ends of the slide rail 5 are respectively fixedly connected to the tops of the two pillars 4, the first slider 6 and the second slider 7 Located in the slide rails 5 respectively, the first detector 8 is fixedly connected to the bottom end of the first slide block 6, and the second detector 9 is fixedly connected to the bottom end of the second slide block 7. A baffle 10 is fixe...

Embodiment 2

[0027] A fixed tooling for wind turbine blade inspection, such as figure 1 , figure 2 As shown, it includes a fixed plate 1, a central axis 2, a turntable 3, a pillar 4, a slide rail 5, a first slider 6, a second slider 7, a first detector 8, a second detector 9, and a baffle 10. Hydraulic cylinder 11, bracket 12, snap ring 13, gear 14, third detector 15, motor 16, wherein fixed disk 1 is connected with central axis 2, turntable 3 is fixedly connected with said central axis 2, and pillar 4 has 2 The two pillars 4 are respectively vertically fixedly connected to the edge of the fixed plate 1, the two ends of the slide rail 5 are respectively fixedly connected to the tops of the two pillars 4, the first slider 6 and the second slider 7 Located in the slide rails 5 respectively, the first detector 8 is fixedly connected to the bottom end of the first slide block 6, and the second detector 9 is fixedly connected to the bottom end of the second slide block 7. A baffle 10 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com