A Continuously Penetrating Mechanical Cross Plate Shear Meter with Clutch Gears

A cross-plate, mechanical technology, applied in the field of mechanical cross-plate shear force meter, can solve the problems of no tube shoe protection, continuous penetration, etc., to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

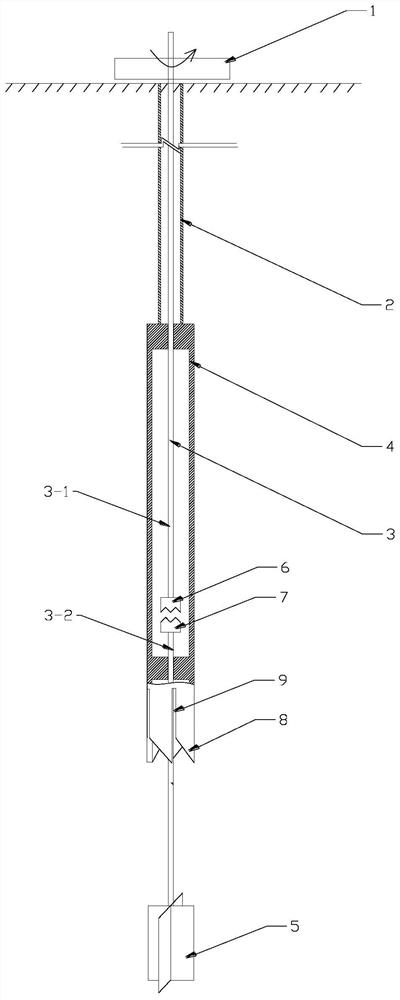

[0040] See attached Figure 1-4 , a mechanical cross-plate shearing instrument with clutch teeth that can be continuously penetrated, including a torque steel ring 1, an outer tube 2, an inner rod 3, a tube shoe 4, and a cross plate 5.

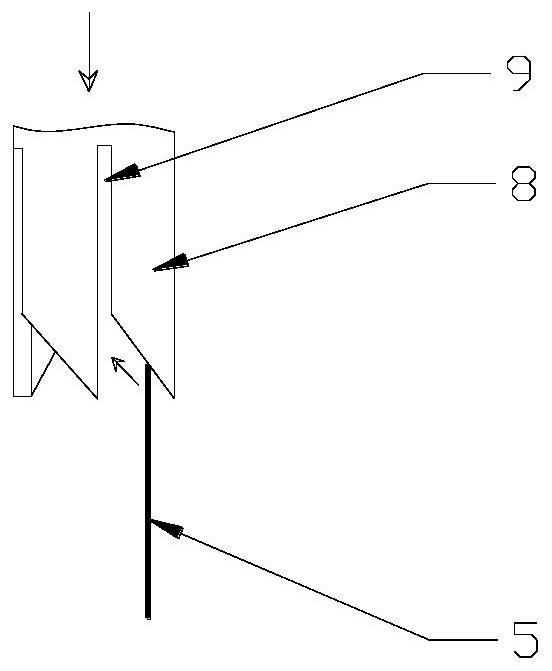

[0041] The bottom end of the outer tube 2 is connected to the boot 4, the inner rod 3 is coaxially arranged in the outer tube 2 and the boot 4, the torque steel ring 1 is set on the top of the inner bar 3, and the upper and lower groups are arranged in the boot 4 Clutch teeth 6 and 7, the inner rod includes an upper rod segment 3-1 and a lower rod segment 3-2, the upper rod segment and the lower rod segment are split, and the bottom end of the upper rod segment 3-1 is fixedly connected to the upper clutch tooth 6 , the top of the lower rod section 3-2 is fixedly connected to the lower clutch tooth 7, and through the cooperation of the upper and lower clutch teeth, the connection and separation between the upper rod section and the lower rod se...

Embodiment 2

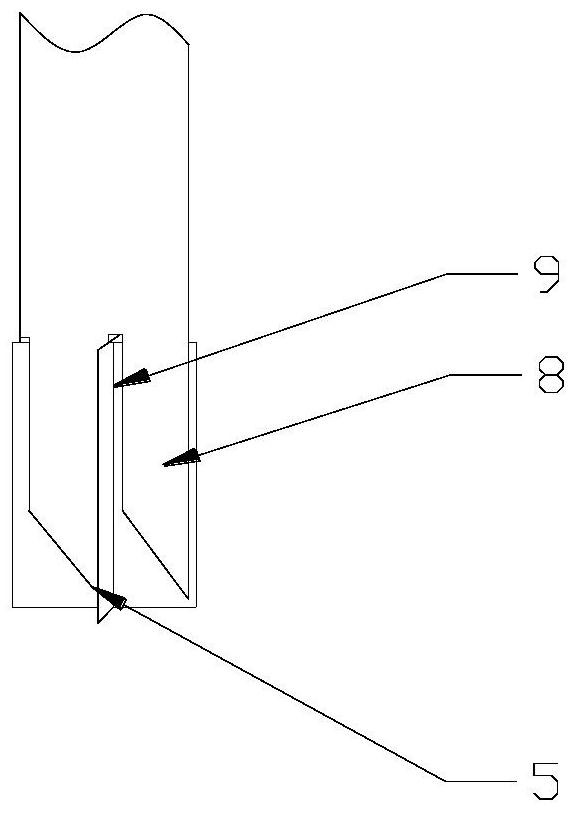

[0058] See attached Figure 5 with 6 The difference between this embodiment and Embodiment 1 is that the wall thickness of the inclined guiding boss 8 is relatively large, and the outer diameter of the cross plate 5 is smaller than the outer diameter of the circular area surrounded by the inclined guiding boss 8 , that is, after the cross plate enters the elongated hole between the guiding inclined bosses, the outer edge of the cross plate 5 is within the outer wall of the guiding inclined boss 8, so that the cross plate can completely enter the tube shoe, thereby more effectively protecting the cross plate plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com