Large model testing device for simulating asymmetric small-distance tunnel excavation process

A model test device, tunnel excavation technology, applied in soil material testing, material inspection products, wellbore/well components, etc., to achieve the effects of easy operation, saving test costs, and easy installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation method of the present invention will be further described below in conjunction with accompanying drawing:

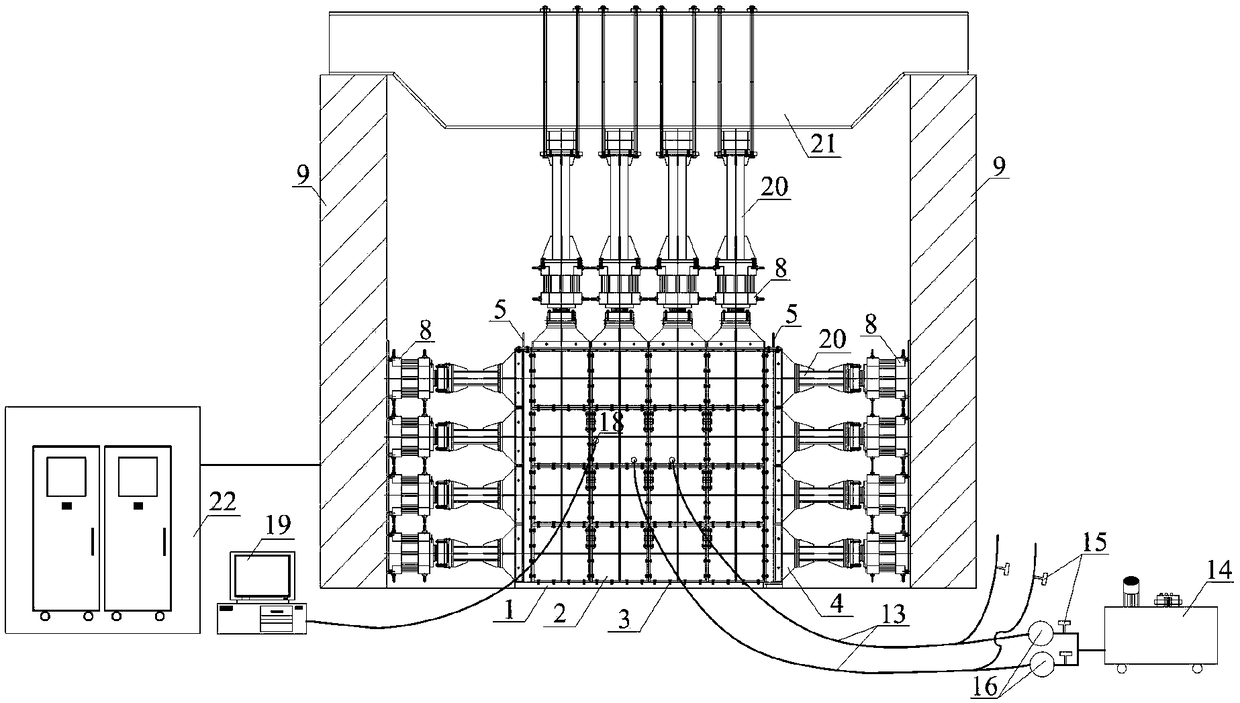

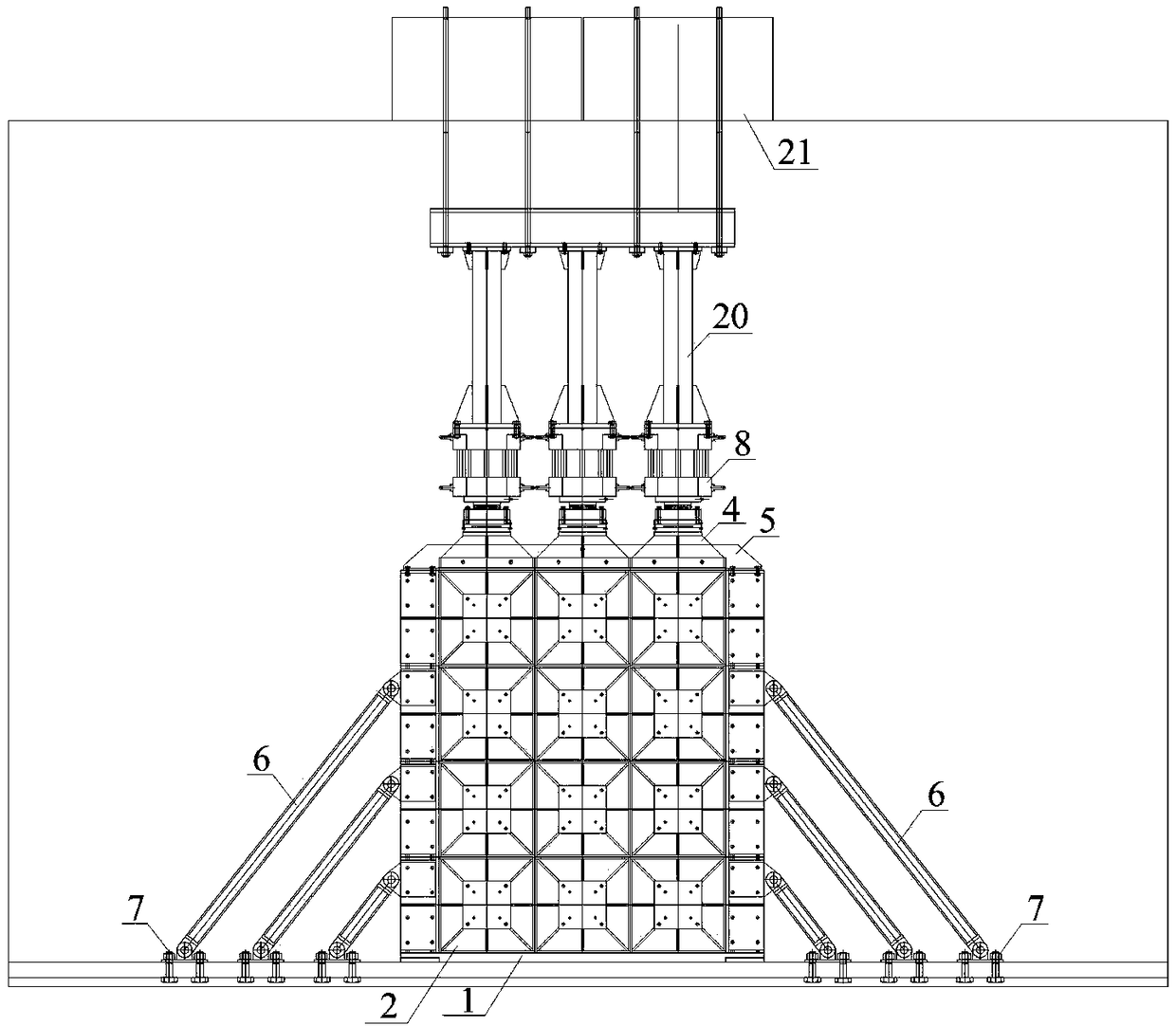

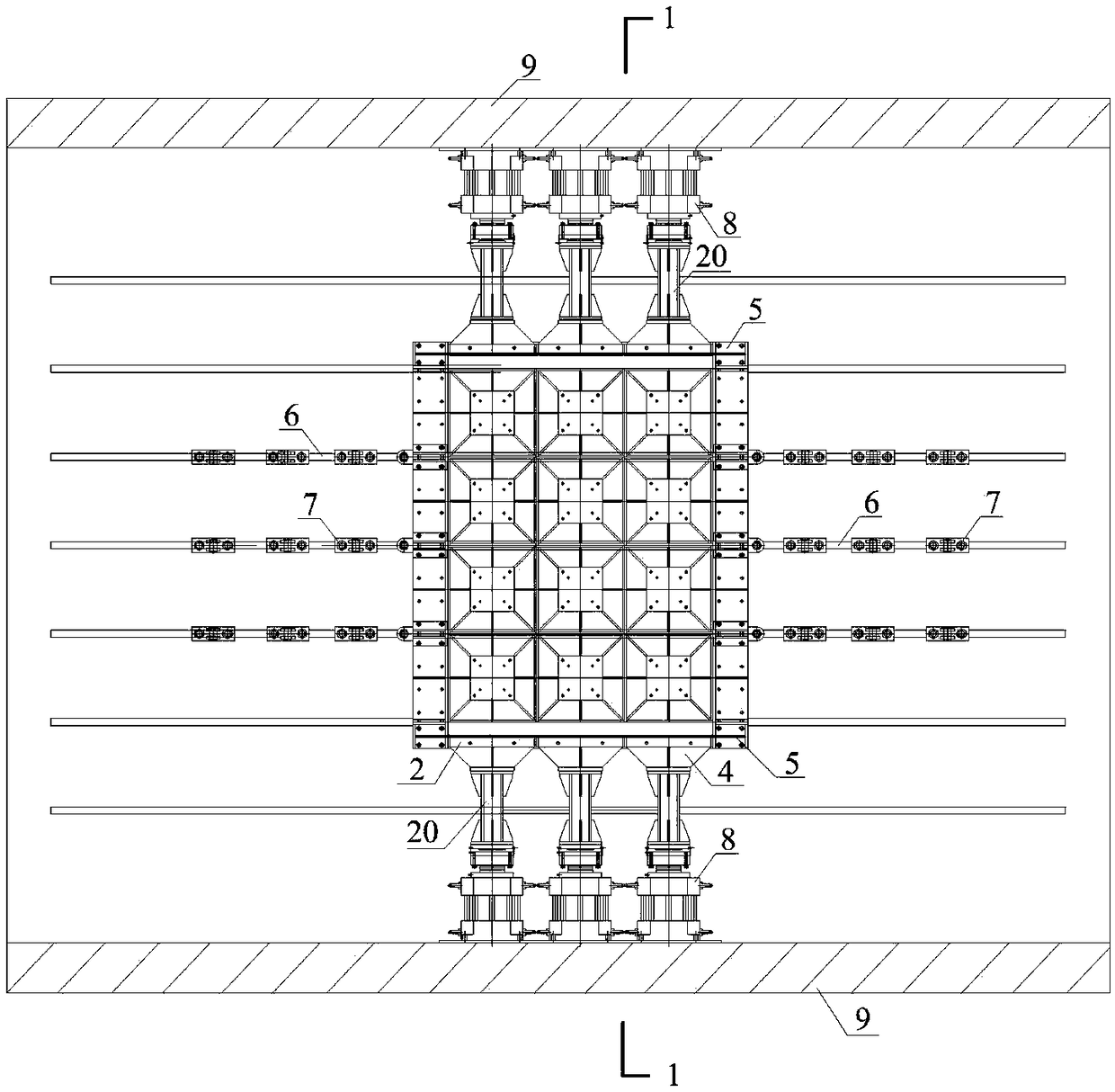

[0028] Such as Figure 1-4 Shown is the core used in the present invention, that is, a large-scale model test device for simulating the excavation process of an asymmetric small-space tunnel, including a model box and a stratum system, a loading and control system, and an asymmetric small-space tunnel structure simulation system, tunnel excavation simulation system, stratum displacement monitoring system, earth pressure monitoring system. The specific operation process is as follows:

[0029] 1. Model box assembly.

[0030] First lay the compression steel plate 1 on the bottom of the model box, then install the first layer of loading plate, the second layer of loading plate, and the third layer of loading plate in sequence according to the number of the loading plate 2, and use M30*80 high-strength bolts 3 to connect each loading plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Carrying capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com