Fast-plug tail cable testing connector

A technology for testing connectors and pigtail cables, applied in the direction of testing/measuring connectors, connections, conductive connections, etc., can solve the problems of abnormal antenna indicators, complex antenna structure, rework and scrap, etc., to achieve convenient operation, good replaceability, electrical The effect of accurate performance test values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

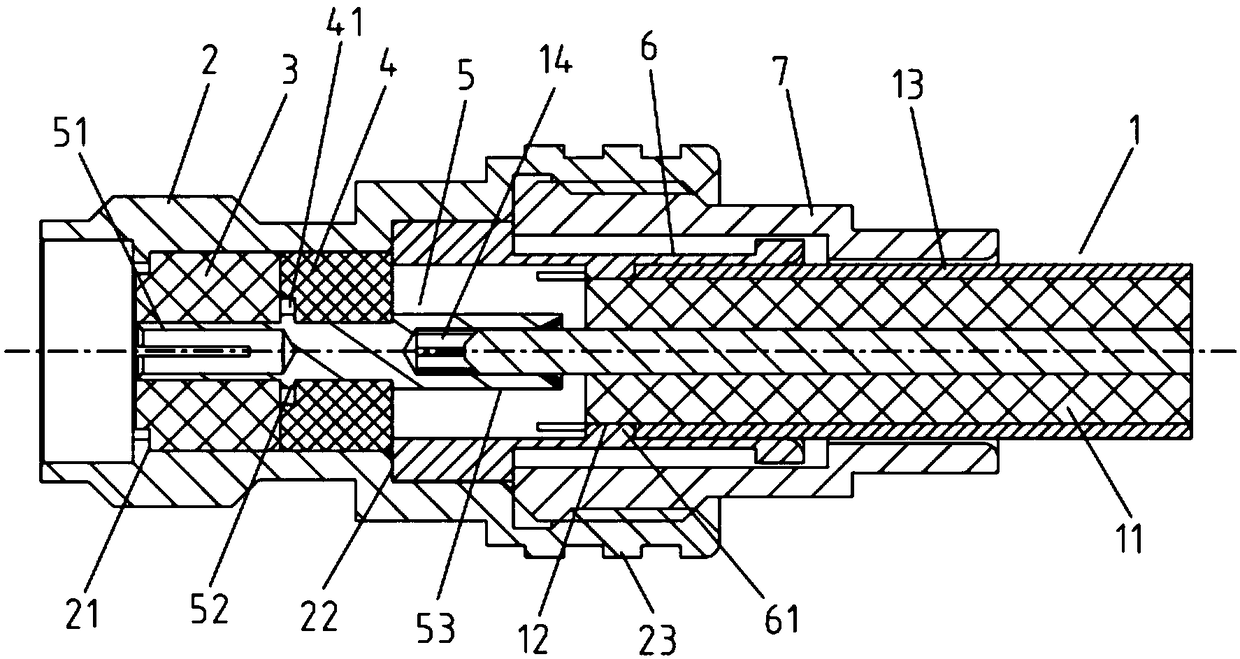

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

[0021] In this embodiment, the end connected to the test system is the front, and the end connected to the cable is the rear.

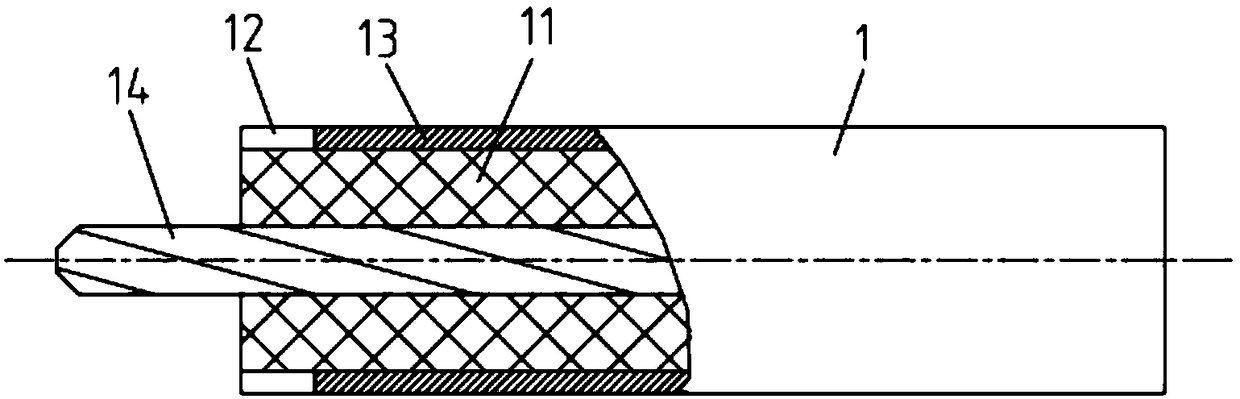

[0022] like figure 1 As shown, after the step of the cable 1 is peeled off, an air dielectric ring 12 is formed at the step of the insulating layer 11 .

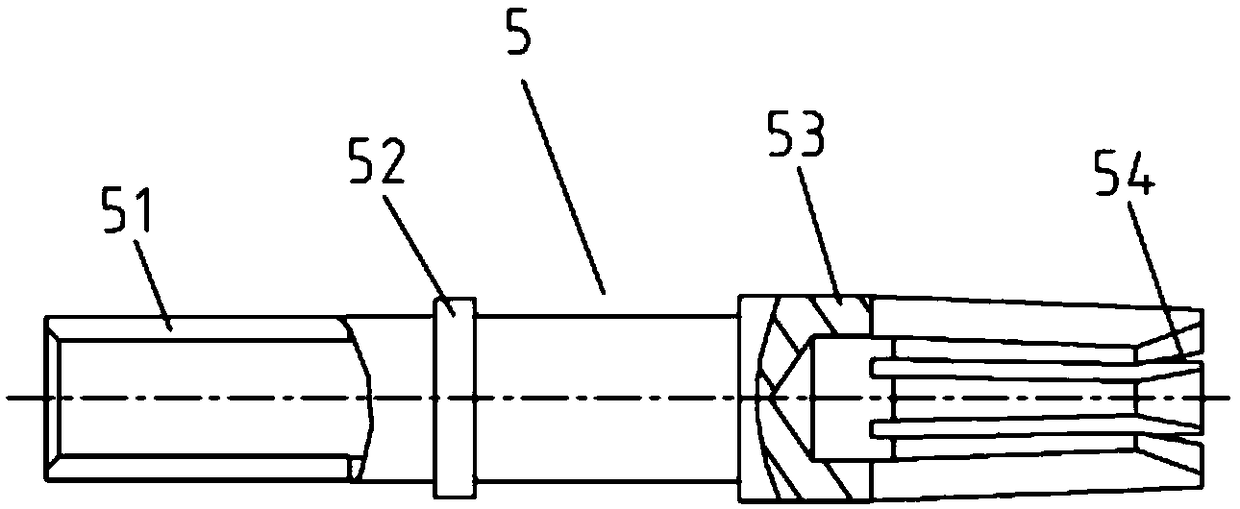

[0023] like figure 2 As shown, the present invention includes a main housing 2 , a front medium 3 , a rear medium 4 , an inner conductor 5 , a clamp 6 and a locking housing 7 . The inner hole of the main housing 2 is a stepped hole structure, and the front medium 3, the rear medium 4, the inner conductor 5 and the wire clip 6 are arranged in the inner hole of the main housing 2 in sequence from front to back, and the front side of the front medium 3 is against the main housing. On the first step 21 of the inner hole of the body 2, the rear medium 4 is fixedly set in the middle of the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com