Heat-removal battery module structure with high energy ratio

A battery module, high-energy technology, applied in battery pack parts, secondary batteries, structural parts, etc., can solve problems such as normal operation of unfavorable single cells, large internal temperature rise, long-term safety and reliability effects, etc. problems, to achieve the effect of convenient and fast wiring, high space utilization, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

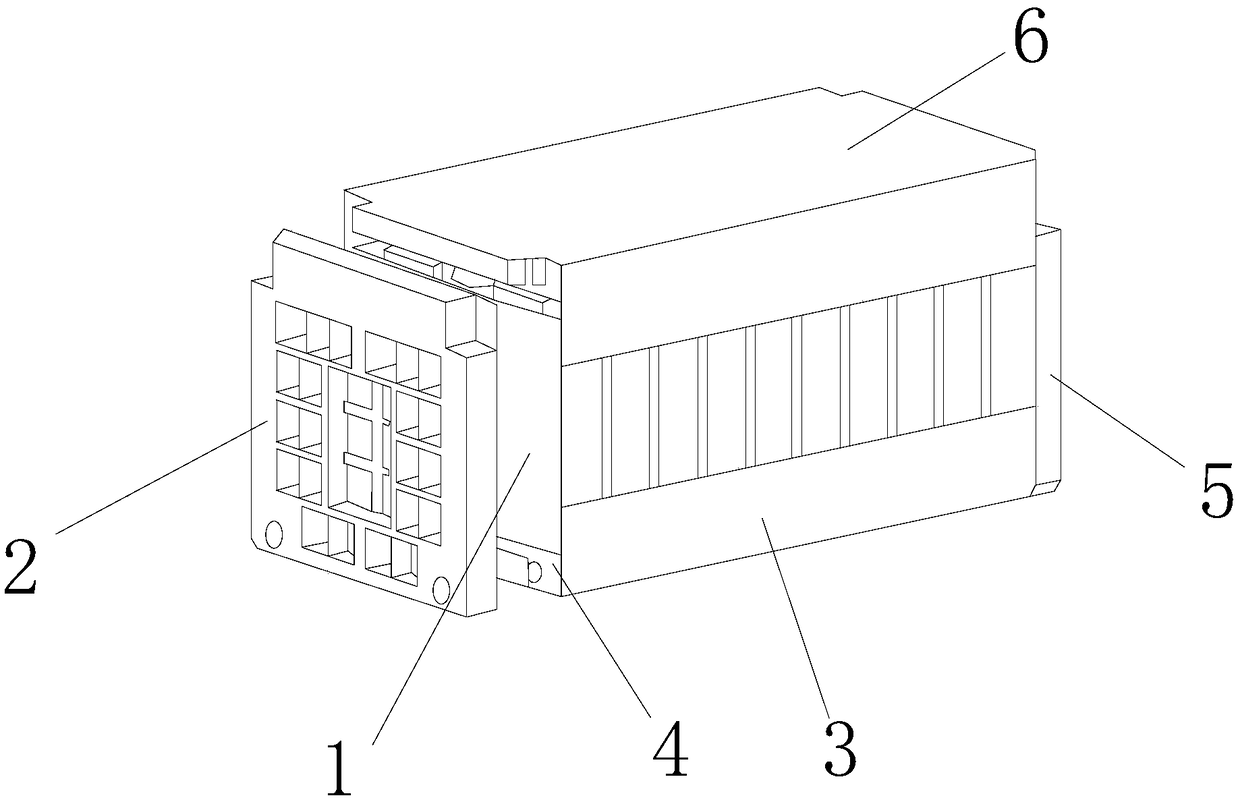

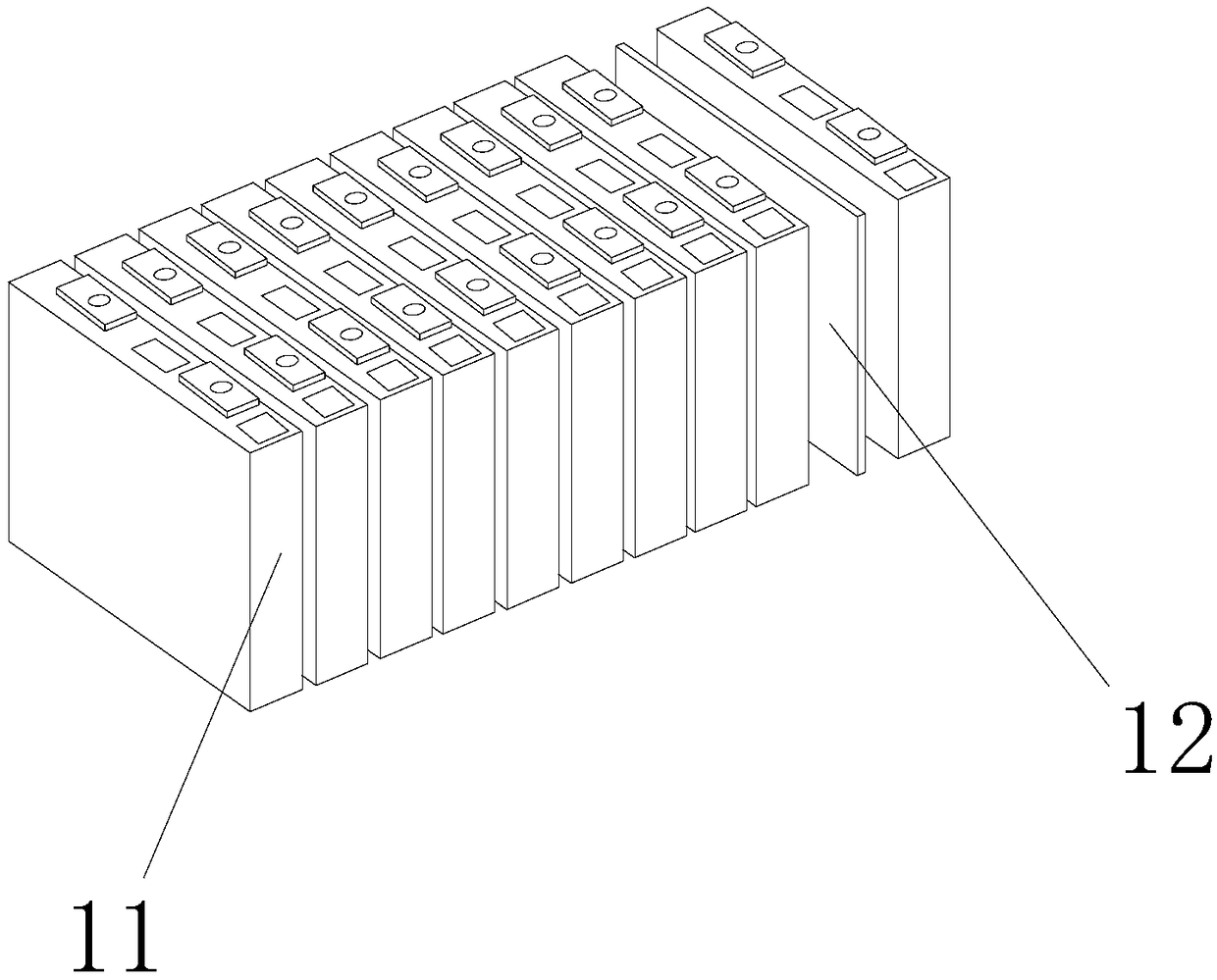

[0020] Such as Figure 1-2 As shown, a battery module structure with high heat dissipation and high energy ratio includes a battery core group 1, and the battery core group includes a plurality of single cells 11, and epoxy plates 12 are arranged between the single cells 11.

[0021] A left ventilation baffle 2 is provided on the left side of the battery core pack 1 , and a right ventilation baffle 5 is provided on the right side. The left ventilating baffle 2 is a baffle made of high-strength plastic material, and the baffle is respectively connected with the upper positioning bracket and the lower heat conducting plate by bonding. The left ventilating baffle is provided with several through Designed ventilation windows. The right ventilation baffle 5 is a baffle made of high-strength plastic material, the baffles are respectively connected with the upper positioning bracket and the lower heat conducting plate by bonding, and a number of penetrating holes are arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com