High-density winding punching plate

A high-density, winding technology, applied in the shape/style/structure of winding conductors, electric components, magnetic circuit shape/style/structure, etc. Guarantees normal use and prevents damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

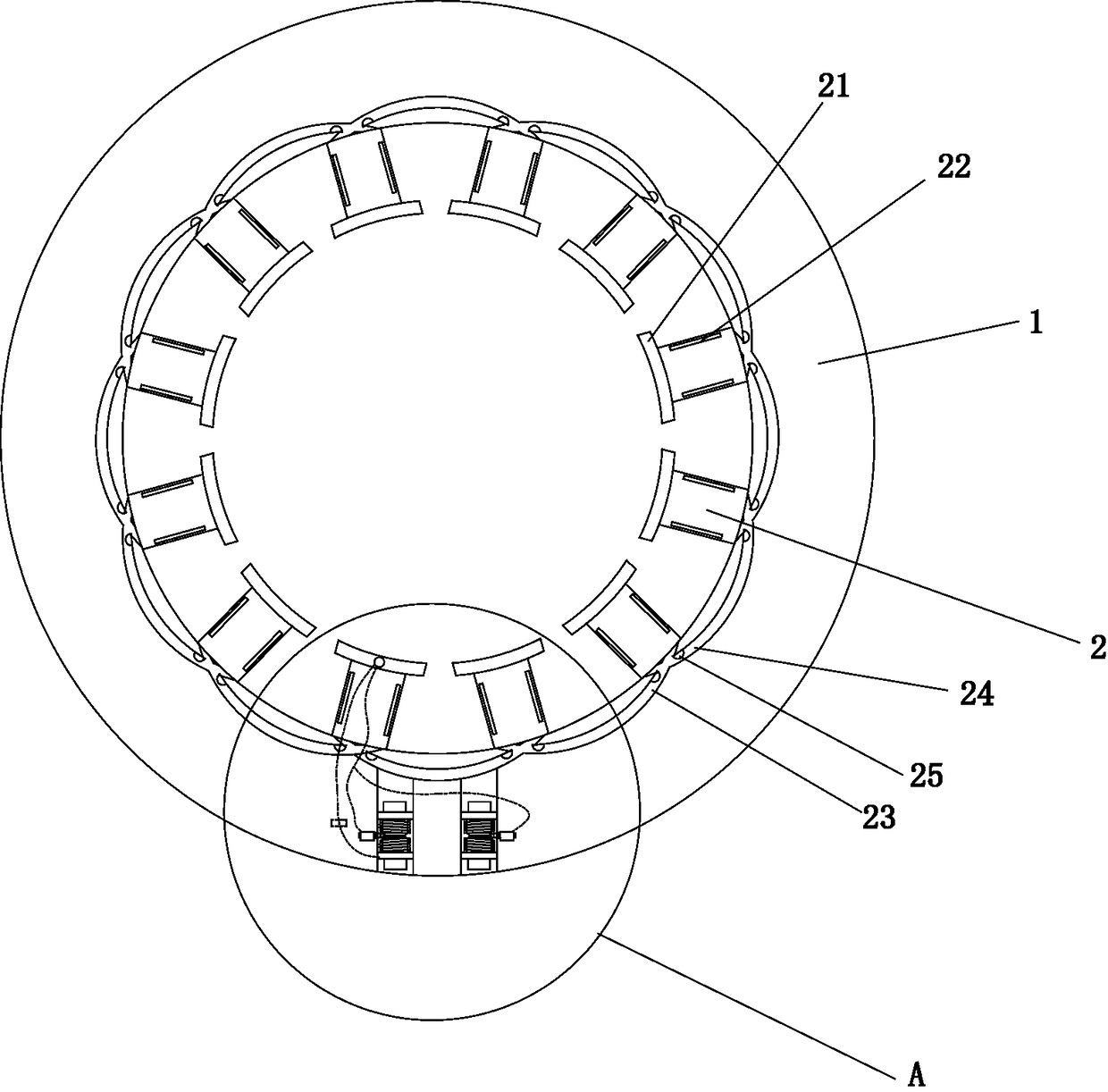

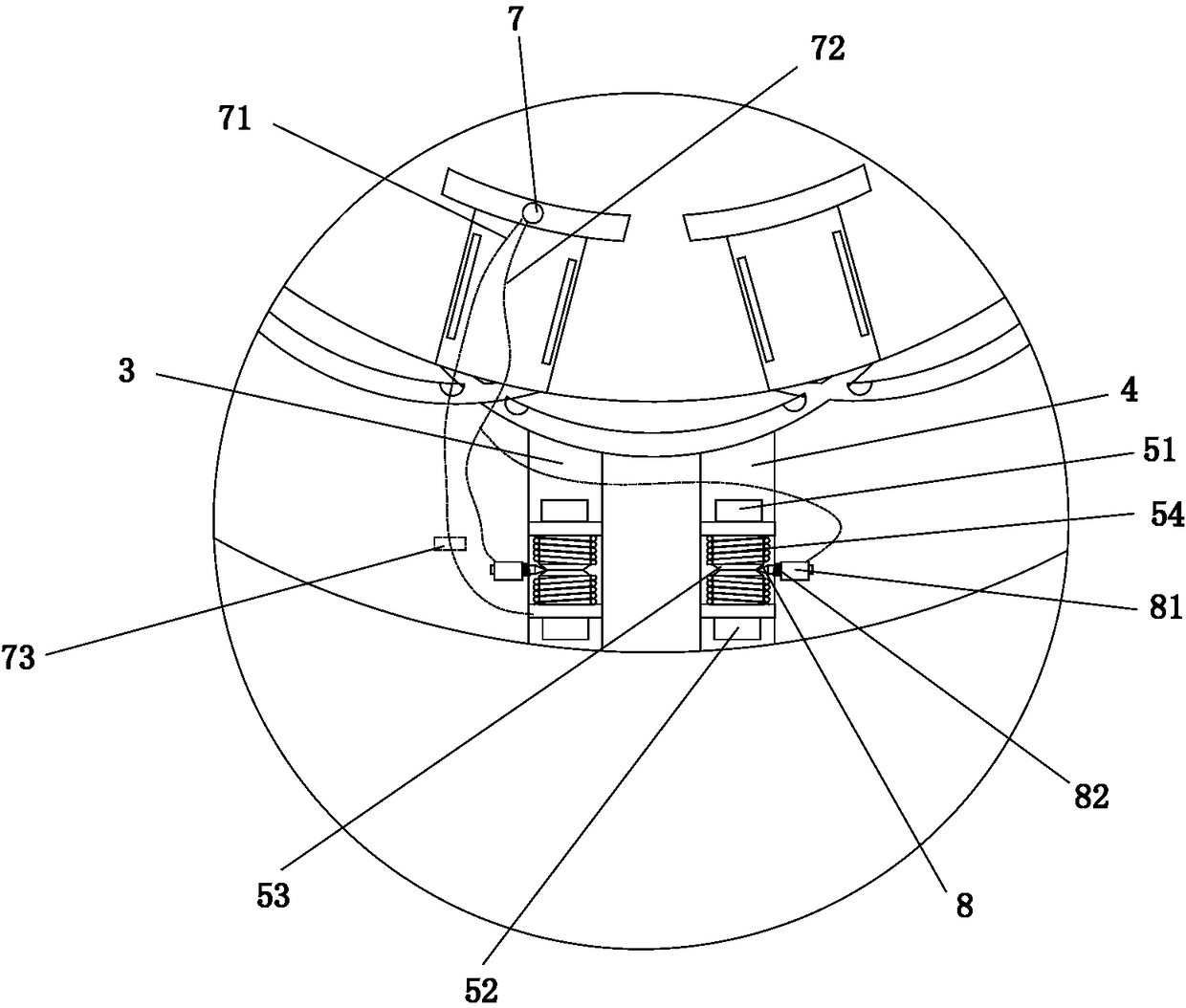

[0017] Embodiment 1: as Figure 1 to Figure 2 As shown, the high-density winding punch includes a yoke 1, and the yoke 1 includes an inner circle, and a number of teeth 2 are arranged on a uniform circumference of the inner circle, and there are between adjacent teeth 2 Arc transition. The top of the tooth portion 2 is provided with a blocking block 21 , and the tooth portion 2 is provided with cooling holes 22 . The surfaces of the yoke portion 1 and the tooth portion 2 are coated with insulating varnish. The yoke 1 is provided with winding entry slots 23 and winding exit slots 24 corresponding to the teeth 2 , and the winding entry slots 23 and winding exit slots 24 are respectively provided with anti-off pieces 25 . The yoke 1 is also provided with a winding wire inlet hole 3 and a winding wire outlet hole 4, and the winding wire inlet hole 3 and the winding wire outlet hole 4 are provided with a front connection end 51 and a rear connection end 52 for connecting the wind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com