Screwdriver component

A screwdriver and component technology, applied in screwdrivers, wrenches, wrenches, etc., can solve problems such as inability to use well, ordinary flat-blade screwdrivers without supporting equipment, and screwdrivers that are difficult to meet daily work needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

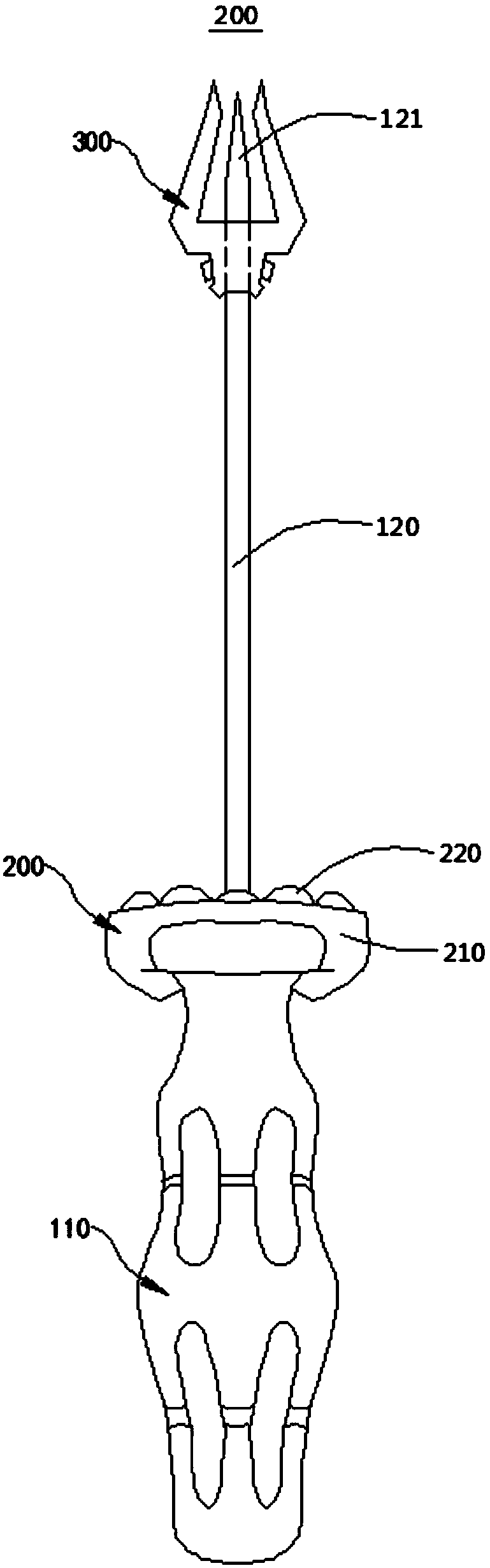

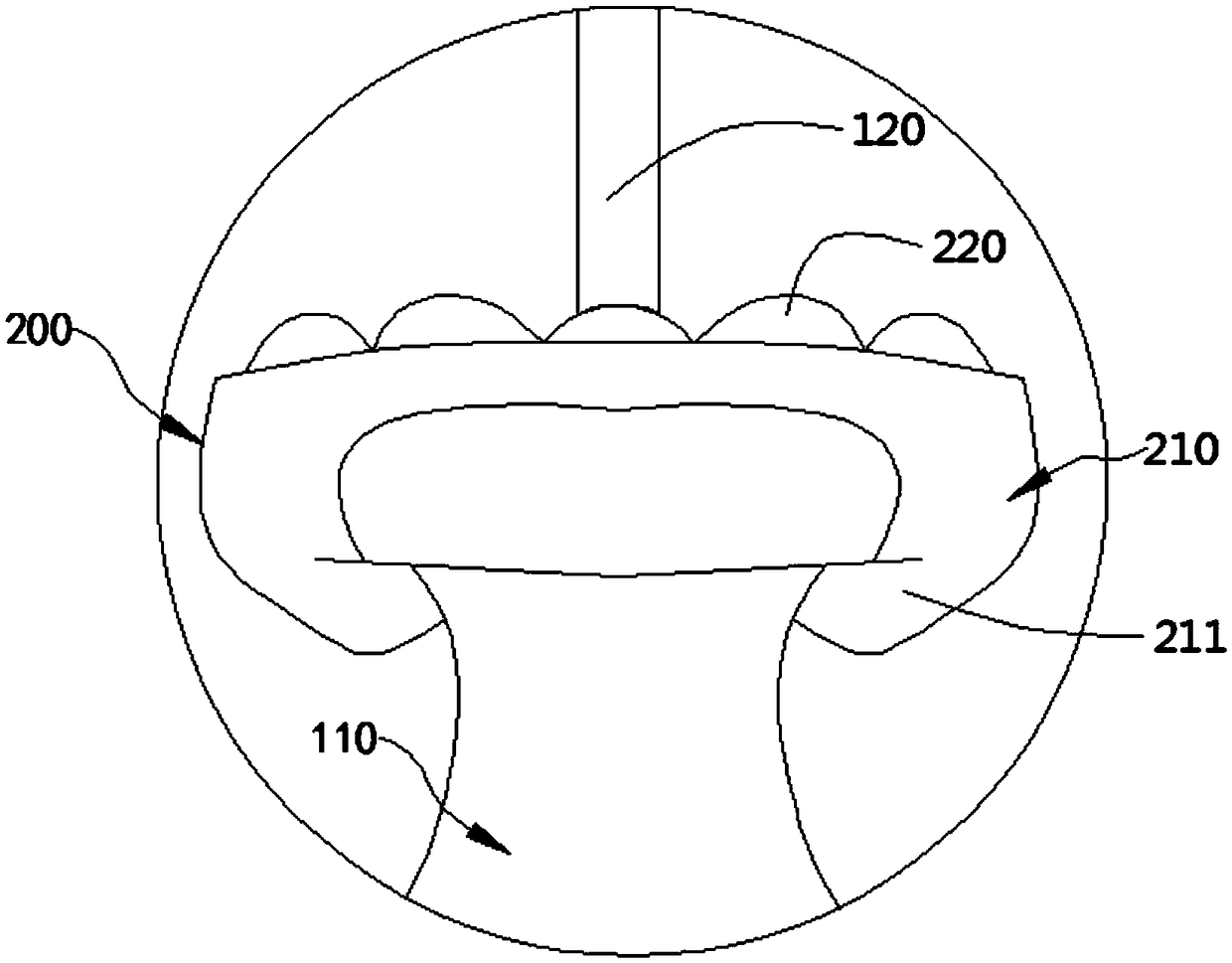

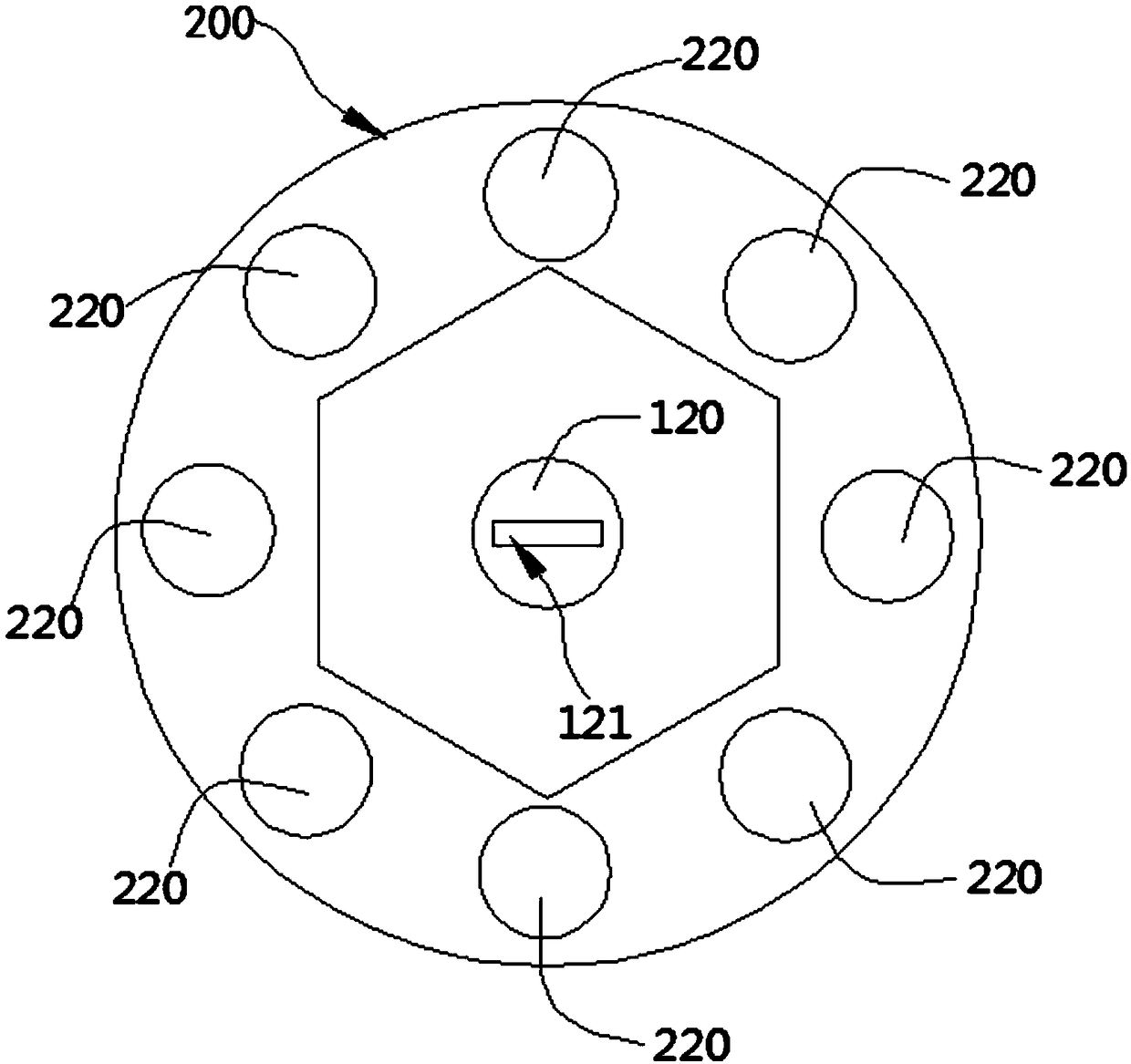

[0048] Please refer to figure 1 , figure 1 It is a schematic structural diagram of a screwdriver assembly 10 provided by an embodiment of the present invention. from figure 1 A screwdriver assembly 10 can be seen in the figure, which includes a body 100 , a lamp base 200 and a bayonet part 300 .

[0049] The body 100, the body 100 includes a knife handle 110 and a knife body 120, and the end of the knife body 120 away from the knife handle 110 has a knife edge 121;

[0050] Lamp cap 200, the lamp cap 200 is set on the body 100, and the lamp cap 200 is configured to emit light and photograph the direction of the knife edge 121;

[0051] The bayonet part 300 , the bayonet part 300 is disposed on the blade body 120 close to the knife edge 121 , and the bayonet part 300 is configured to increase the extension area of the knife edge 121 .

[0052] The common flat-blade screwdriver in existing use does not have supporting equipment, and function is too single. In the process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com