Prefabricated inspection well die and technology thereof for manufacturing inspection well

A technology for inspection wells and molds, applied in molds, manufacturing tools, strengthening molding, etc., can solve problems such as uneven product quality, low production efficiency, unreasonable inspection well molds or unreasonable processes, and achieve good product quality and production efficiency. High, fast combined effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

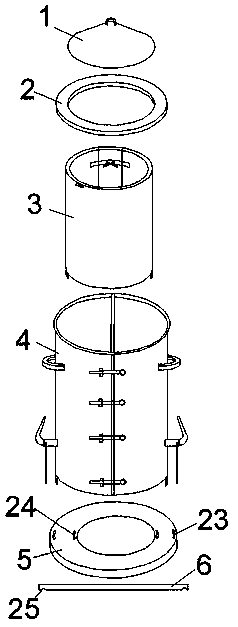

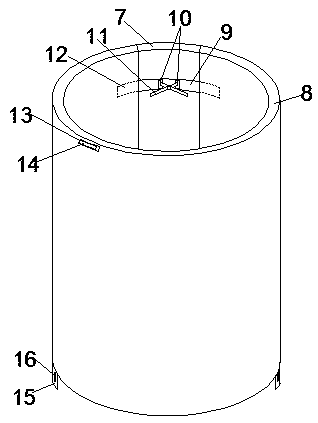

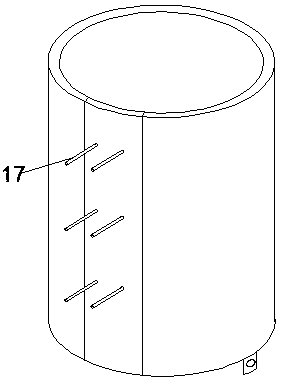

[0033] Example 1 A prefabricated inspection well mold, see figure 1 , including an outer mold 4, an inner mold 3, a bottom tray 5, an inner mold cover 1 and a well ring mold 2. During installation, the outer mold is set outside the inner mold, and an annular cavity is formed between the outer mold and the inner mold. The inner mold cover is conical, and its bottom surface is in contact with the top of the inner mold, and the bottom tray is installed under the inner mold and the outer mold. The outer mold includes two vertically symmetrical semi-cylindrical outer mold units, the corresponding vertical sides of the two outer mold units are hinged by hinges, and the corresponding vertical sides of the other side are provided with a plurality of latches along the edge Type clamp 20, unclamping or locking the bolt type clamp can quickly disassemble or combine the outer mold. There are two symmetrically arranged outer mold feet 22 extending downward from the bottom of the outer mol...

Embodiment 2

[0038] Embodiment 2 A process for making an inspection well, comprising the following steps:

[0039] S1. Clean the prefabricated inspection well mold and apply a release agent on the outer surface of the inner mold and the inner surface of the outer mold;

[0040] S2. After assembling the mold, put the reinforcement skeleton into the annular cavity and fit the skeleton with the groove of the steel rod on the inner mold;

[0041] S3. Send concrete into the annular cavity through the distributor until the feeding height is 2-4cm higher than the height of the inner mold;

[0042] S4. Hoist and transfer the mold containing concrete to the plate vibrator, after vibrating for 5 minutes, cover the well ring mold, compact it, and let it stand for 5-10 minutes;

[0043] S5. Remove the well ring mold and the inner mold cover, open the latch type clamp and the hasp, pull out the short rod, and after taking off the outer mold, hold the support rod tightly to separate the arc-shaped plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com