Improved carrying cart

An improved material cart technology, which is applied to trolleys, motor vehicles, multi-axis trolleys, etc., can solve the problems of heavy workload and achieve the effect of improving the efficiency of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

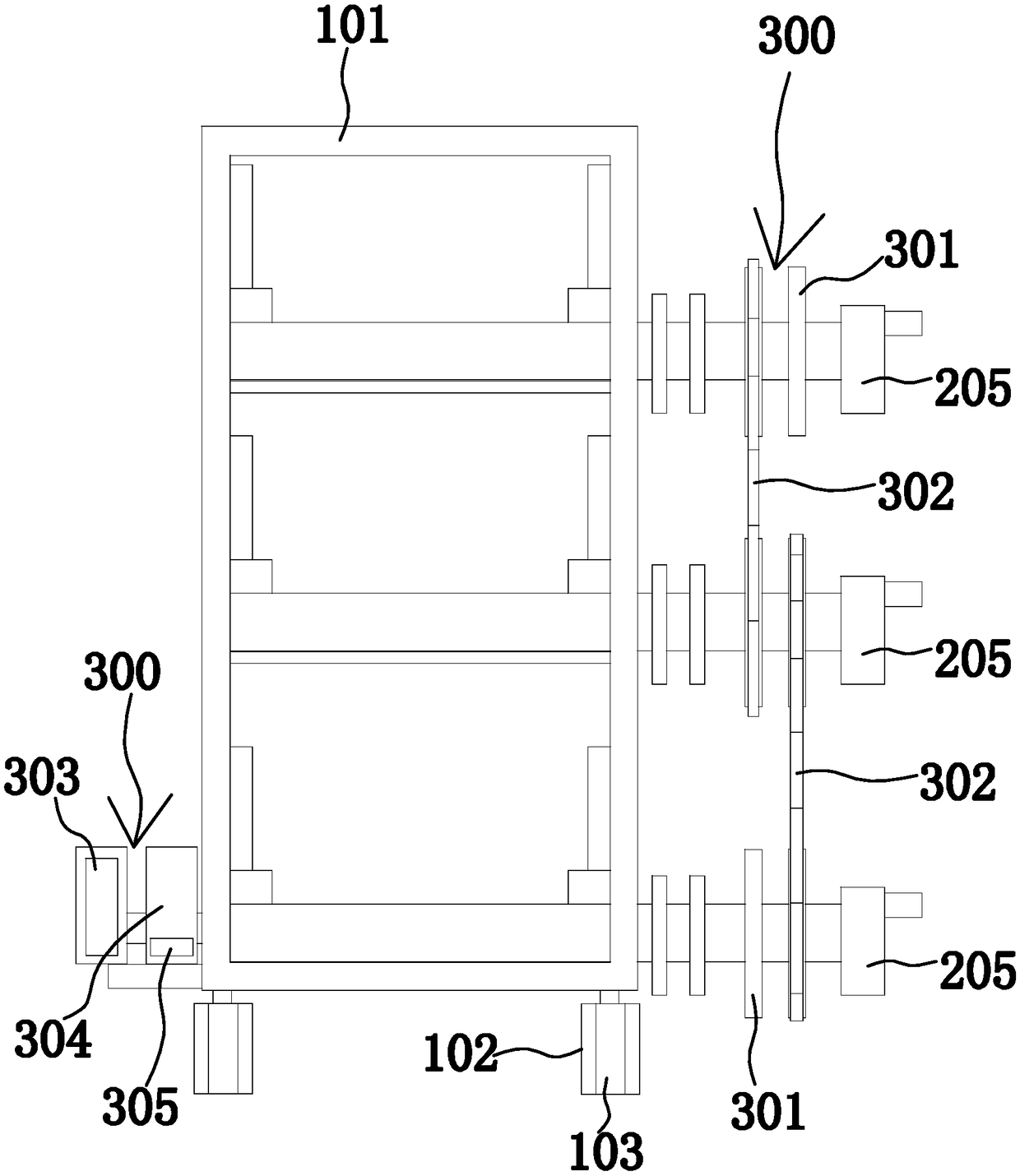

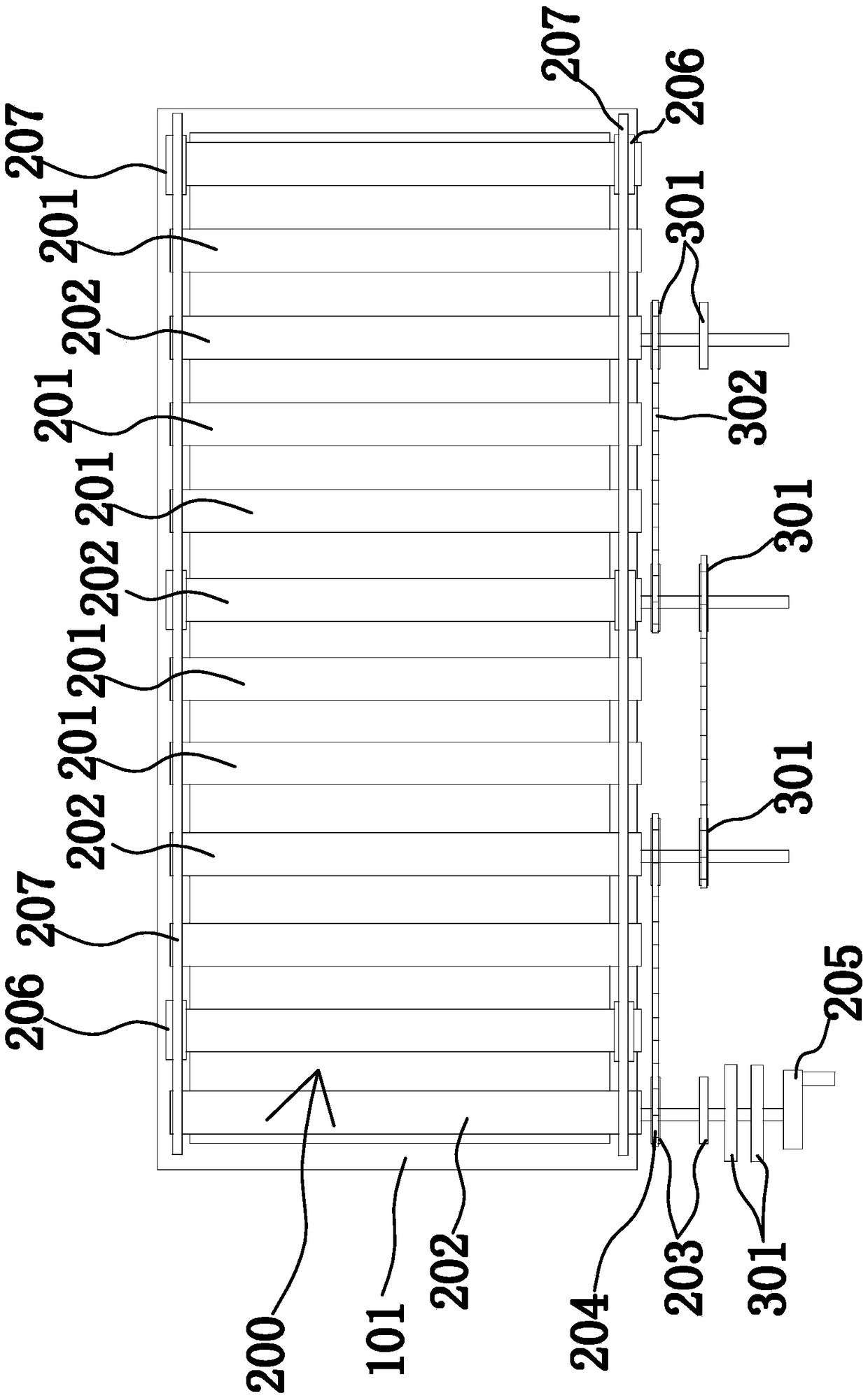

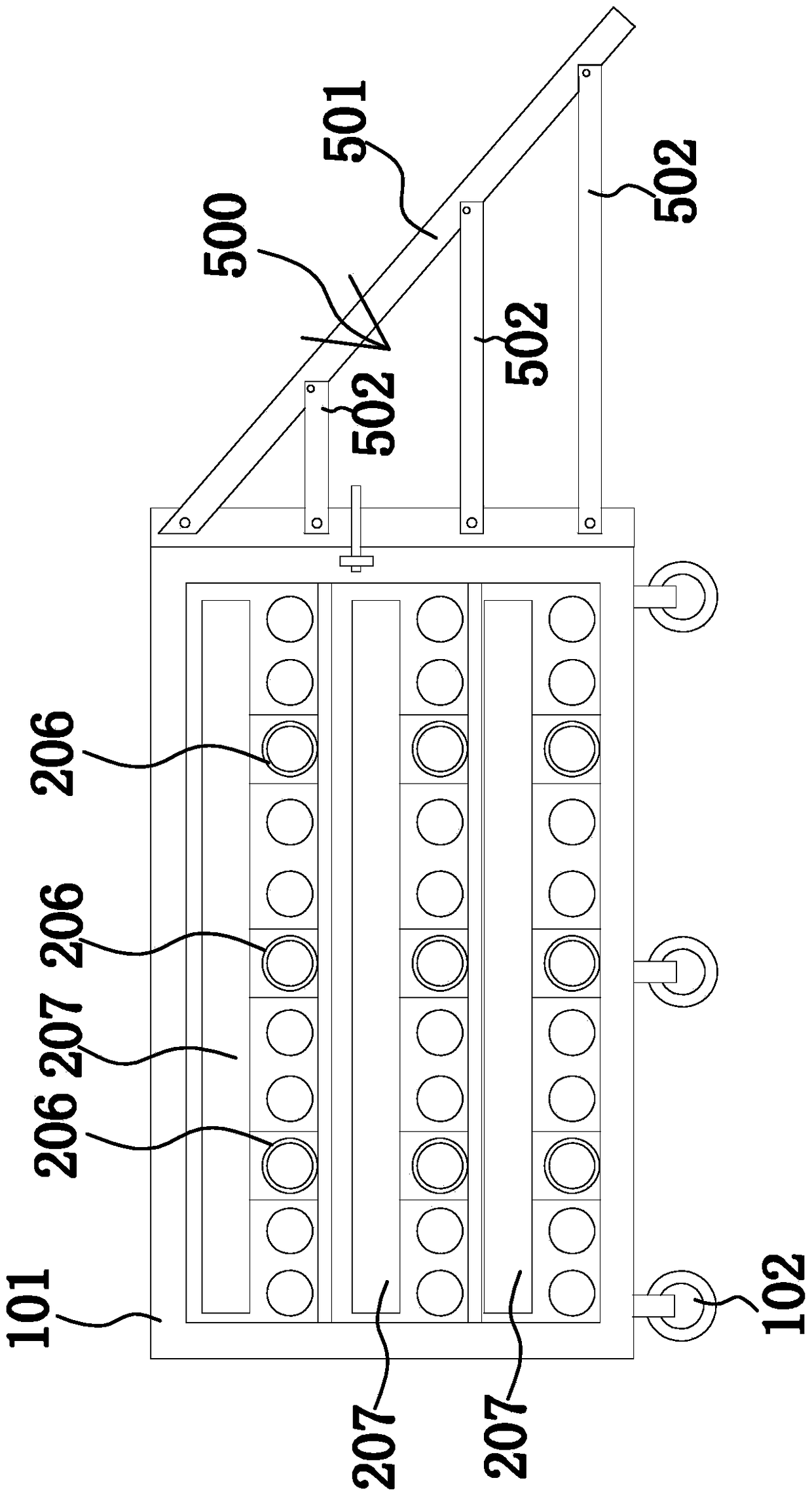

[0018] Such as Figures 1 to 5 As shown, the improved material handling vehicle includes a carrier frame 101, and a plurality of carrier wheels 102 are provided on the bottom side of the carrier frame 101. The manual roller conveying structure 200, the manual roller conveying structure 200 includes a number of driving rollers 201 with two ends respectively arranged on the lateral sides of each layer on the carrier frame 101, and a number of driving rollers are arranged at intervals in all the driving rollers 201 202, two first driving sprockets 203 are coaxially provided on the same end of the axial direction on all driving rollers 202, and a pair of corresponding first driving sprockets 203 on each adjacent two dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com