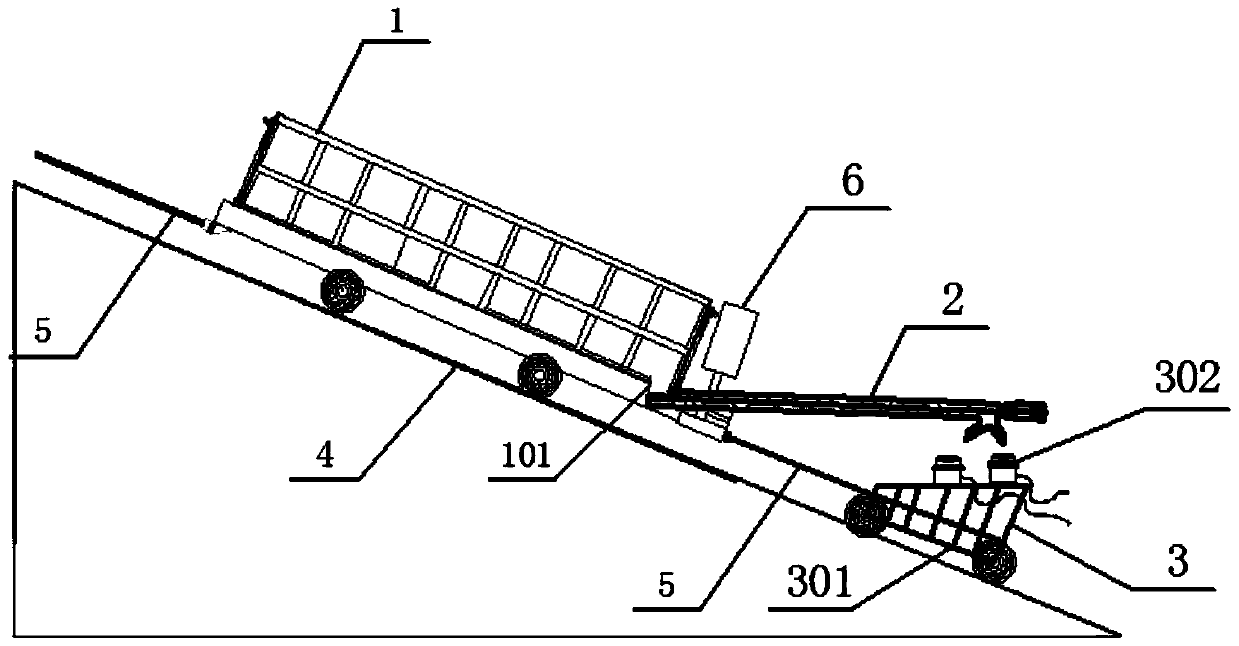

Full-automatic sprayed concrete conveying and unloading equipment and concrete conveying and unloading method

A fully automatic technology of sprayed concrete, applied in mining equipment, earth square drilling, shaft equipment, etc., can solve problems such as damage to the floor of inclined shafts, labor and time-consuming operations, waste of sprayed coagulation, etc., and achieve the goal of improving efficiency and saving construction Time and labor saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

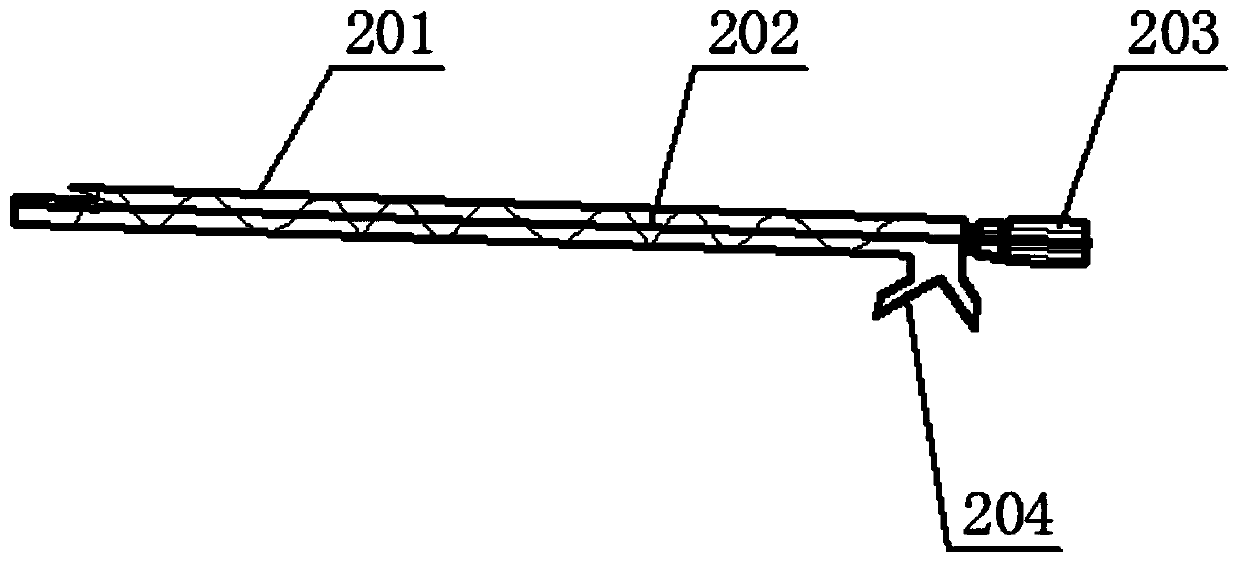

[0044]According to an embodiment of the present invention, preferably, the concrete conveying device 2 includes: an arc-shaped conveying trough 201 with an upper opening, a screw conveyor 202 and a power assembly 203; the conveying trough 201 is used for The two concrete sprayers 302 convey concrete, and the feeding end of the conveying trough 201 is provided with a blanking port 204; the screw conveyor 202 is installed in the conveying trough 201 for spraying concrete from the The discharge port of the hopper 1 is transported to the feed ports of the two concrete injectors 302; connect. The concrete in the hopper 1 enters the arc-shaped conveying trough 201 through the discharge port 101, and the power assembly 203 is started to drive the screw conveyor 202 to rotate, and the concrete in the conveying trough 201 is transported to the discharge port 204 , and can be dropped into the two concrete sprayers 302 from the discharge port 204 .

[0045] The arc-shaped conveying tro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com