High-efficiency PAP composite filter element

A composite filter element and high-efficiency technology, which is applied in the field of water purification, can solve the problems of large space occupation, easy to separate out and pollute the post-stage filter element, and complicated pipelines, and achieve the effect of reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the description of these embodiments is used to help understand the present invention, but does not constitute a limitation to the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not conflict with each other.

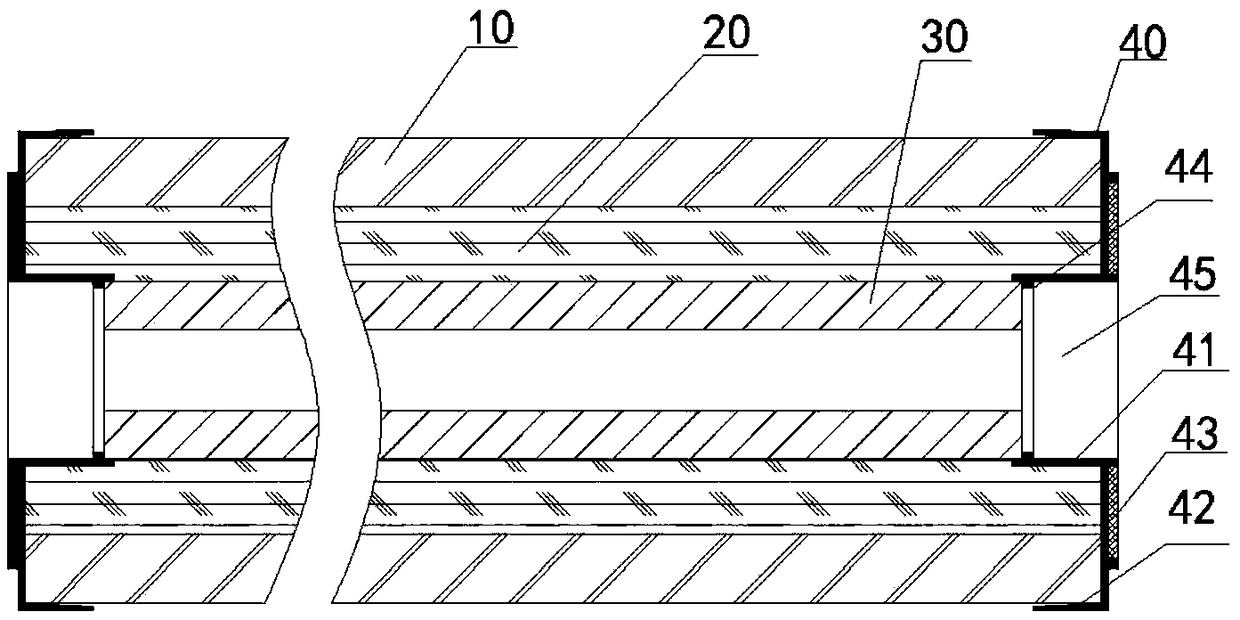

[0016] Such as figure 1 As shown, a high-efficiency PAP composite filter element provided by the present invention includes an outer layer of PP cotton 10, a middle layer of activated carbon 20, and an inner layer of PP cotton 30 rolled into a cylindrical shape. The three layers are in close contact; the outer layer of PP cotton 10 has a filtration accuracy greater than The filtering accuracy of the inner layer of PP cotton 30, the middle layer of activated carbon 20 is formed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| filtration accuracy | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| filtration accuracy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com