A foam glass vertical locked roof system and a construction method thereof

A standing seam and roof system technology, applied to roofs, roof coverings, roofs using flat/curved panels, etc., can solve problems such as damage, prevent slack, disperse wind load transmission, ensure performance and The effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

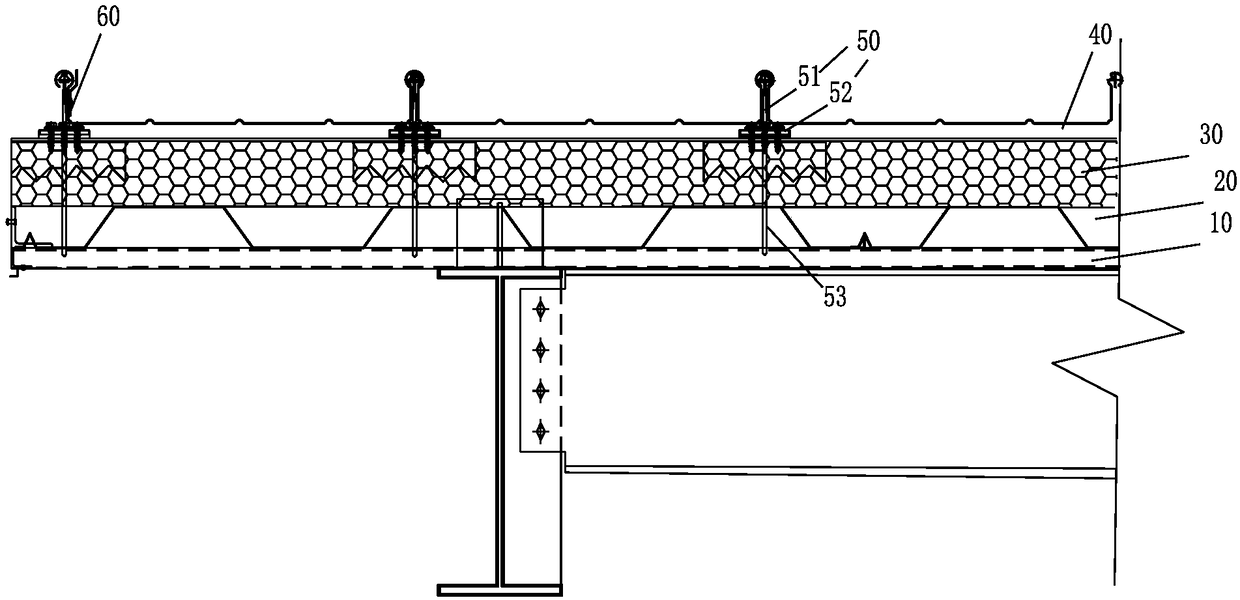

[0031] Combine below figure 1 The structural composition of the cellular glass standing seam roof system of the present invention is described in detail.

[0032] Please refer to figure 1 , a foam glass standing seam roofing system, which includes a profiled steel plate 20, a foam glass plate 30, a metal plate 50 and a standing seam roof panel 40 arranged sequentially from the roof structure base 10 to the surface layer; wherein, the profiled steel plate 20 includes crest sections and trough sections arranged at intervals, the trough section of the profiled steel plate 20 is fixedly connected to the roof structure base 10 through connectors; the foam glass plate 30 is fixed above the crest section of the profiled steel plate 20 by an adhesive; the vertical lock The side roof panel 40 is fixed on the foam glass plate 30 by a plurality of metal discs 50 arranged at intervals, and the teeth discs 51 of the metal discs are embedded in the foam glass plate 30 to realize the occlus...

Embodiment 2

[0044] Please continue to refer figure 1 , the present invention also provides the construction method of cellular glass standing seam roofing system, and this construction method comprises:

[0045] Step 1. Set the profiled steel plate 20, foam glass plate 30, metal plate 50 and standing seam roof panel 40 on the roof structure base 10 in sequence, and the profiled steel plate 20 is fixedly connected to the trough of the roof structure base 10 through connectors The foam glass plate 30 is fixed on the top of the profiled steel plate 20 by an adhesive; the standing seam roof panel 40 is fixed on the foam glass plate 30 by a plurality of metal discs 50 arranged at intervals, and the tooth discs 51 of the metal disc are embedded in the foam glass plate 30 In order to realize the occlusal connection of the two, the fastening screw 53 longitudinally passes through the support 51, the tooth plate 52, the foam glass plate 30 and the profiled steel plate 20 and drives into the base l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com