Improved Pipe Wrench

An improved pipe wrench technology, applied in the direction of wrench, manufacturing tools, wrench, etc., can solve the problems of easy collapse of pipe body or pipe wrench, tight arrangement of pipe body, hidden safety hazards, etc., to reduce the risk of accidents Probability, high-efficiency torsion of the pipe body, and the effect of preventing the jaws from falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

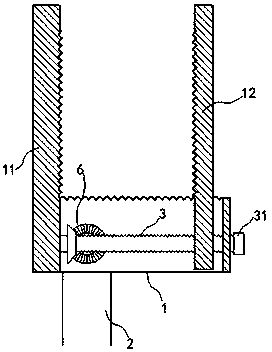

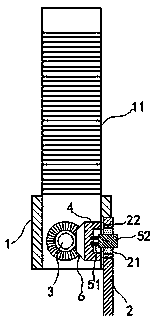

[0022] exist figure 1 , figure 2 In the first shown embodiment, the improved pipe wrench includes a pliers head 1 and a handle 2;

[0023] One side of the pliers head 1 is provided with a fixed pliers mouth 11, and the other side of the pliers head 1 is provided with a movable pliers mouth 12, and the movable pliers mouth 12 is parallel to the fixed pliers mouth 11; Between the mouths 12, an adjusting screw 3 is vertically installed, and the adjusting screw 3 can freely rotate around its own axis; a screw hole matching the adjusting screw 3 is provided on the movable jaw 12, and the adjusting screw 3 passes through the screw hole. The pincer head 1 protrudes from the hole, and a reset knob 31 is provided at the end of the adjusting screw rod 3 protruding from the pincer head 1; the movable jaw 12 can move close to or away from the fixed jaw 11 along the axis of the adjusting screw rod 3;

[0024] A driving gear 4 is also installed on the pliers head 1, and the adjusting scr...

Embodiment 2

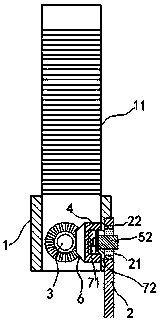

[0032] exist image 3 In the shown second embodiment, different from the first embodiment, the clutch in this embodiment includes a coaxially arranged clutch unit 71, a transmission disc 72, and a sliding column 52; the clutch unit 71 is a push pop-up member , the push pop-up member can be compared to the reciprocating pop-up structure on an automatic ballpoint pen, which is relatively common; it will not be described in detail in this embodiment; the transmission disc 72 is meshed with the drive gear 4, and the transmission disc 72 is fixedly connected with the sliding column 52; The sliding column 52 is coaxial and engaged with the inner ring of the one-way bearing 21; the sliding column 52 can slide along its own axis; as image 3 As shown; when the clutch unit 71 pops up, the transmission disc 72 does not contact the drive gear 4; compared with Embodiment 1, the contact area between the transmission disc 72 and the drive gear 4 is larger, and the transmission stability and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com