a tile

A technology for ceramic tiles and water inlet chambers, applied in covering/lining, buildings, floors, etc., can solve problems such as turbid air, large amount of dust, and poor aesthetics of splicing joints, so as to reduce dust amount and beautify installation joints Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

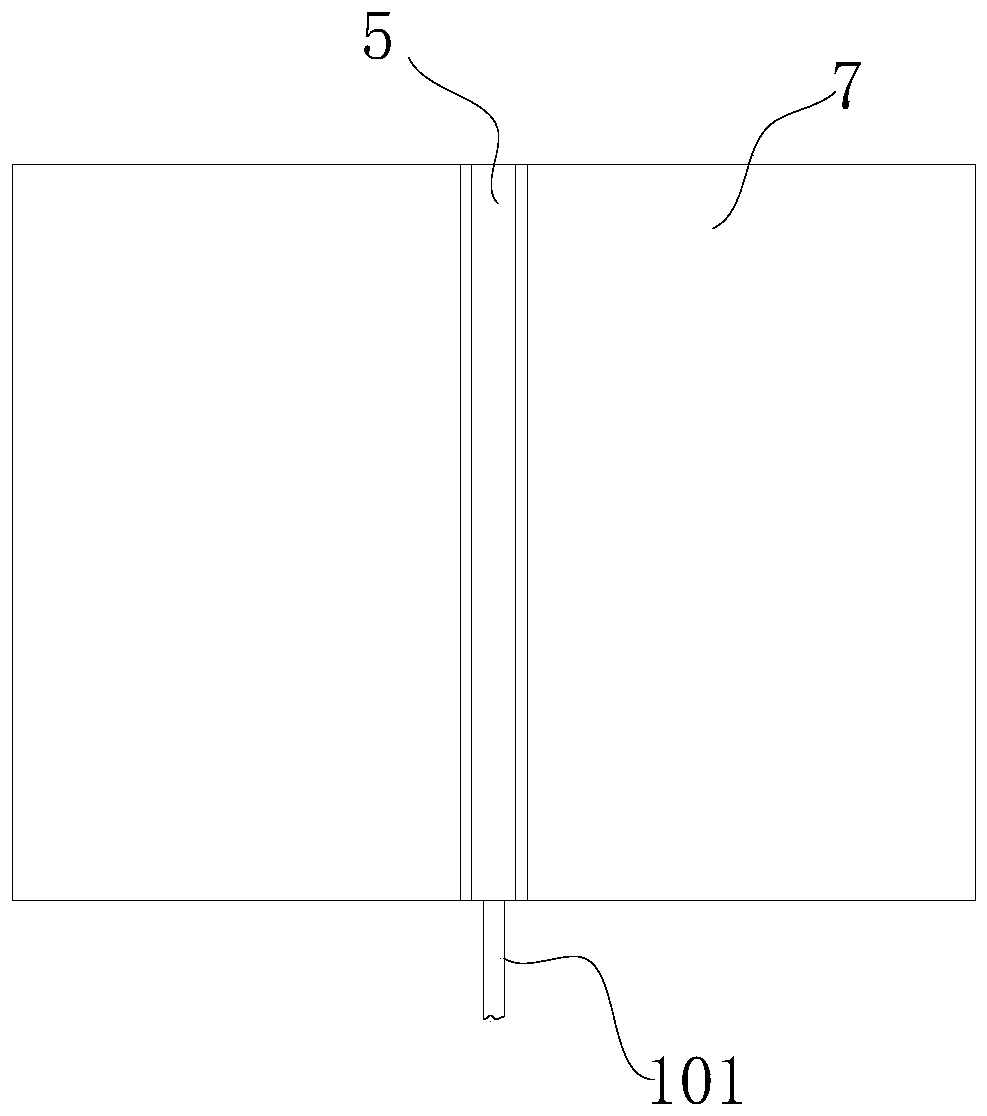

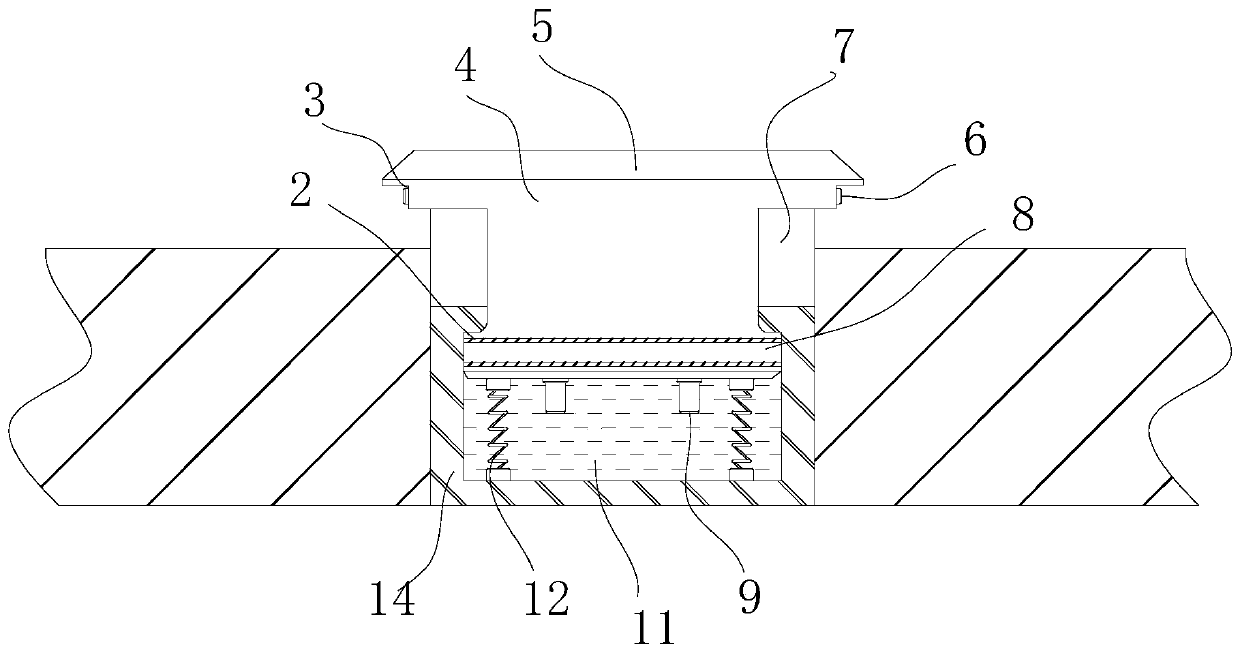

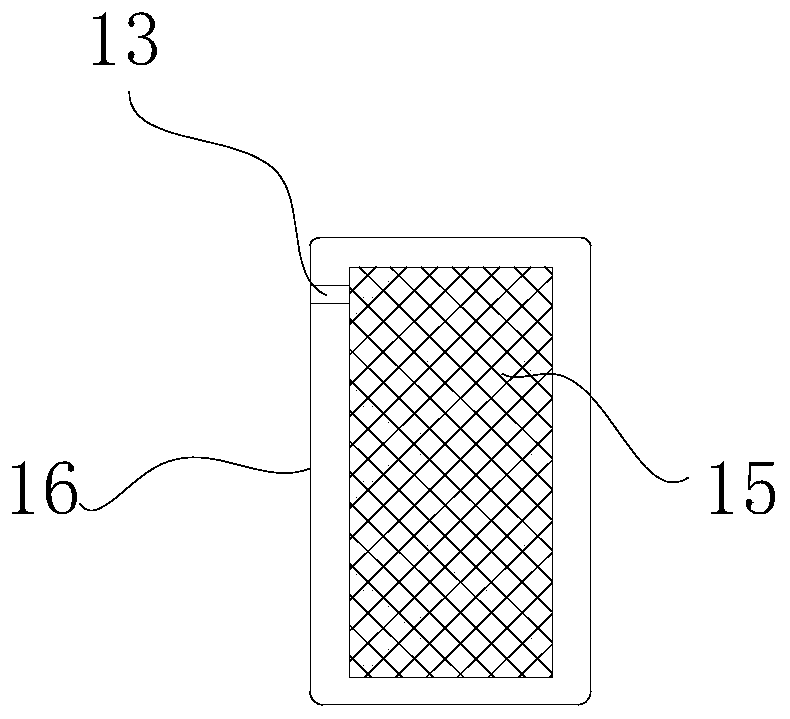

[0019] Such as figure 2 As shown, a ceramic tile includes more than one ceramic tile 7, an installation joint is formed between two adjacent ceramic tiles 7, a base bar 14 is installed in the installation joint, and there is a water inlet cavity 11 in the middle of the base bar 14, and the The upper end surface of the water chamber 11 is open, and a limit rib is respectively arranged on both sides of the upper end opening end. The input end of the base bar 14 is connected to a water inlet pipe 101, and the output end of the water inlet pipe 101 communicates with the water inlet chamber 11, and the water inlet A mounting strip 4 is loaded into the cavity 11, and the top of the mounting strip 4 is provided with a decorative layer 5 extending toward the two ends of the mounting strip, and a concave cavity 3 is provided at the bottom of the outer end of the decorative layer 5; the decorative layer 5 covers the mounting seam all the time, so that it cannot be seen, such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com