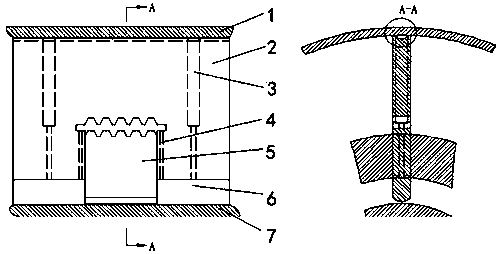

Primary-secondary vane structure of hydraulic motor

A vane structure and hydraulic motor technology, applied in the field of hydraulic components, can solve the problems of fatigue damage, wear, affecting the service life of the vane motor, etc., and achieve the effect of improving the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

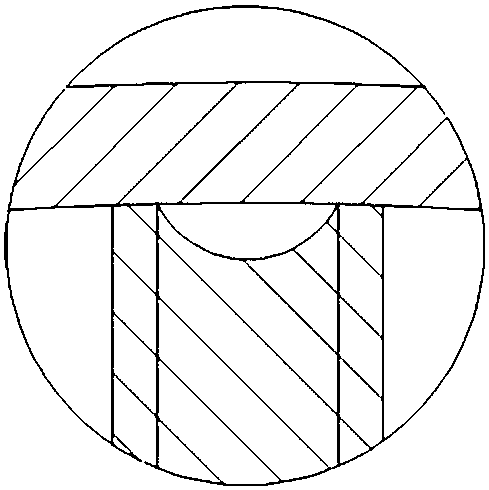

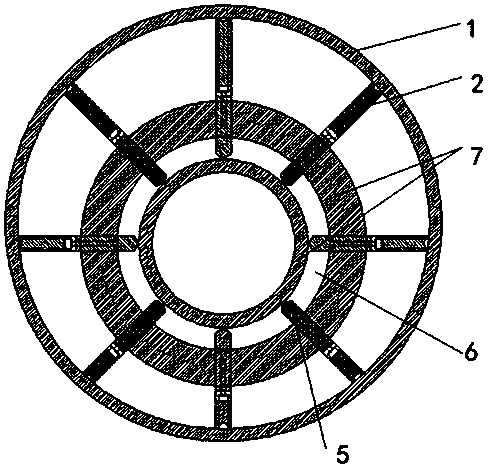

[0015] A blade structure for a hydraulic motor according to the present invention is shown in the figure. The sub-blade 5 is inserted into the lower middle position of the mother blade 2, and then the sub-blade and the mother blade are installed between the stator 1 and the rotor 7, wherein the mother blade 2 There is an oil channel 6 between the root of the rotor and the rotor 7, and the installation position of the mother blade 2 and the daughter blade 5 is a tooth-shaped structure, which increases the oil film area between the mother blade 2 and the daughter blade 5, and plays a better supporting role. There are two symmetrical long oil holes 3 in the blade 2, allowing the oil in the oil passage 6 to enter the arc-shaped groove on the top of the mother blade 2 from the long oil holes 3, so as to realize the up and down movement of the mother blade 2. The pressure is balanced. The long oil hole 3 includes two sections of thickness. When the hydraulic oil enters the thicker se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com