Full-automatic while drilling gas content quick determination device

A technology for rapid determination of gas content, applied in sampling devices, analytical materials, instruments, etc., can solve the problems of large gas loss and long coal sample leakage time, and achieve the effect of reducing intervention, shortening measurement time, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

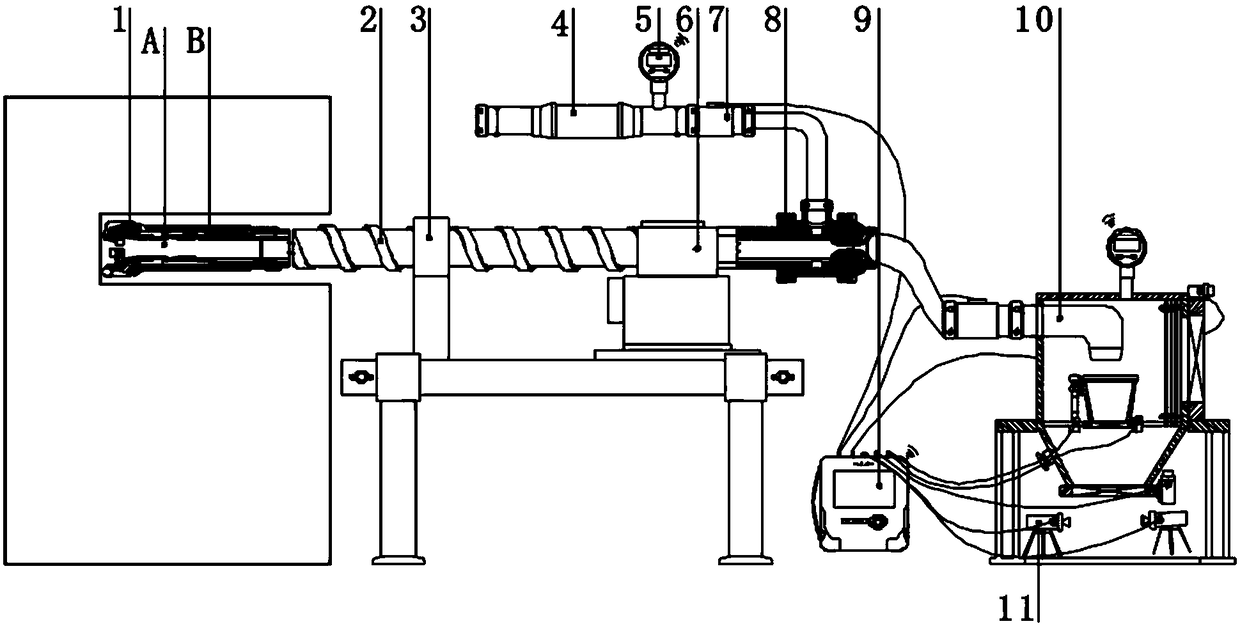

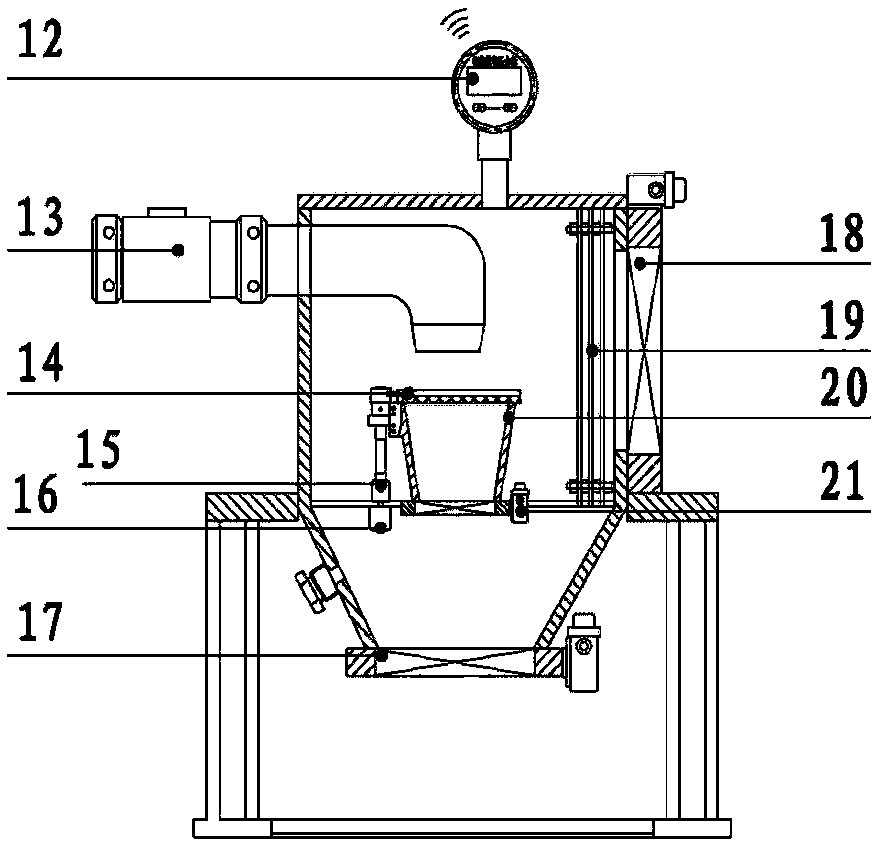

[0020] Such as figure 1 The full-automatic gas content rapid determination device while drilling shown includes sampling device, measuring device and connecting pipes; each component is described in detail below:

[0021] The sampling device includes a double-arm drill rod 2 fixed on the frame by a holder 3, a sampling drill bit 1 arranged at the front end of the double-arm drill rod 2 and a drill tail 8 arranged at the tail of the double-arm drill rod 2 The double-arm drill rod 2 is driven by the drilling rig 6, the double-arm drill rod 2 is provided with a main channel A, and the wall of the double-arm drill rod 2 is provided with an annular space B communicating with the main channel A, and the drill tail 8 is provided with an air pressure stabilizing device. The air pressure stabilizing device includes a pressure stabilizing pipeline connected to the drill tail 8, a pressure gauge A5 is provided on the pressure stabilizing pipeline, and an opening adjustable ball valve is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com