Apparatus for resetting spiral armored steel wires

A technology of armored and outer steel wires, applied in the field of steel wire armored cables, which can solve the problems of steel wire surface coating damage, troublesome operation, and uneven arrangement of steel wires, etc., to achieve reduced corrosion resistance, uniform arrangement, and reduced loss of tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

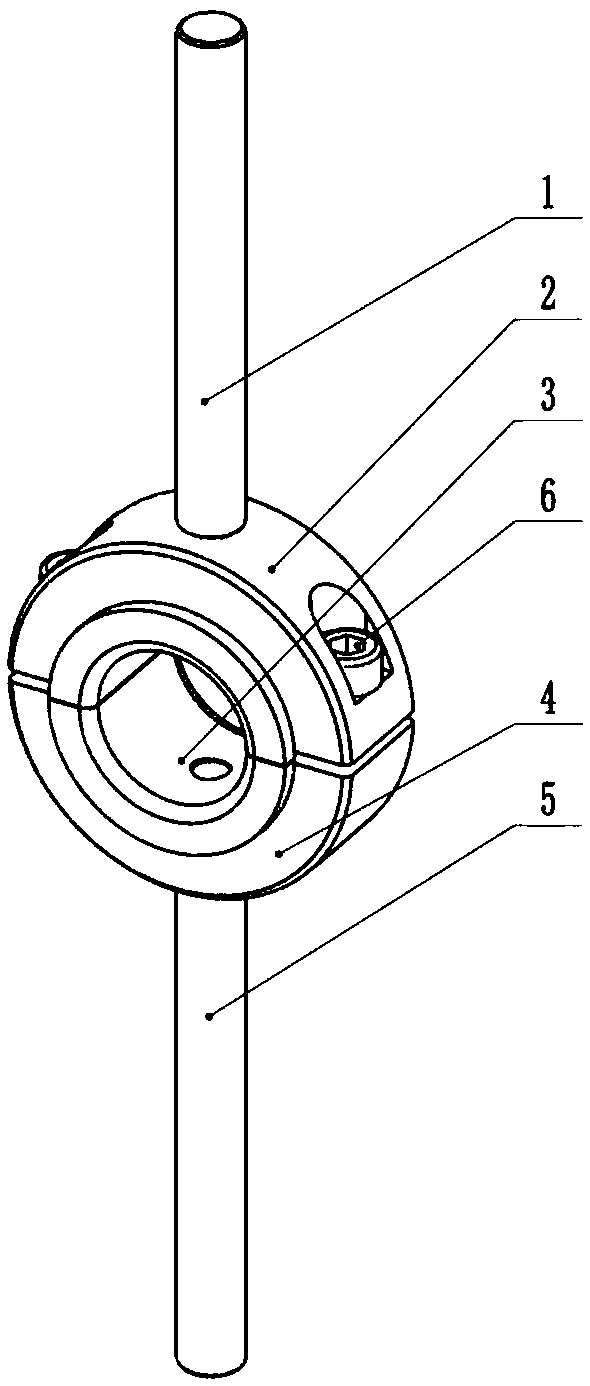

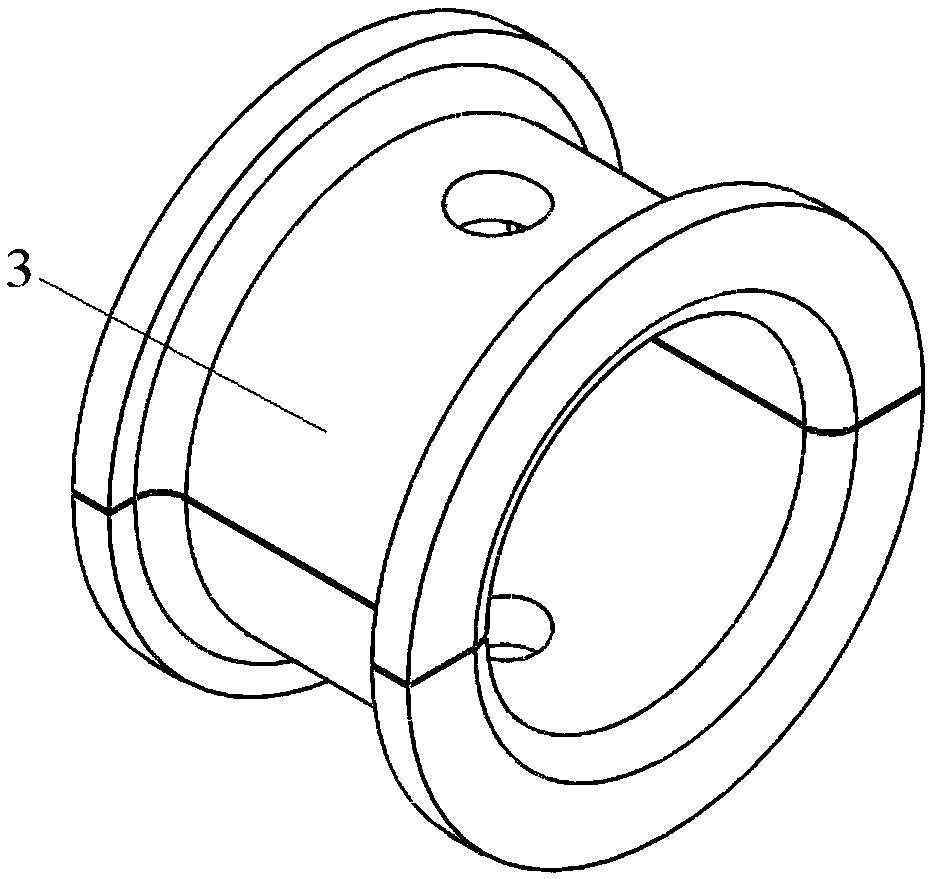

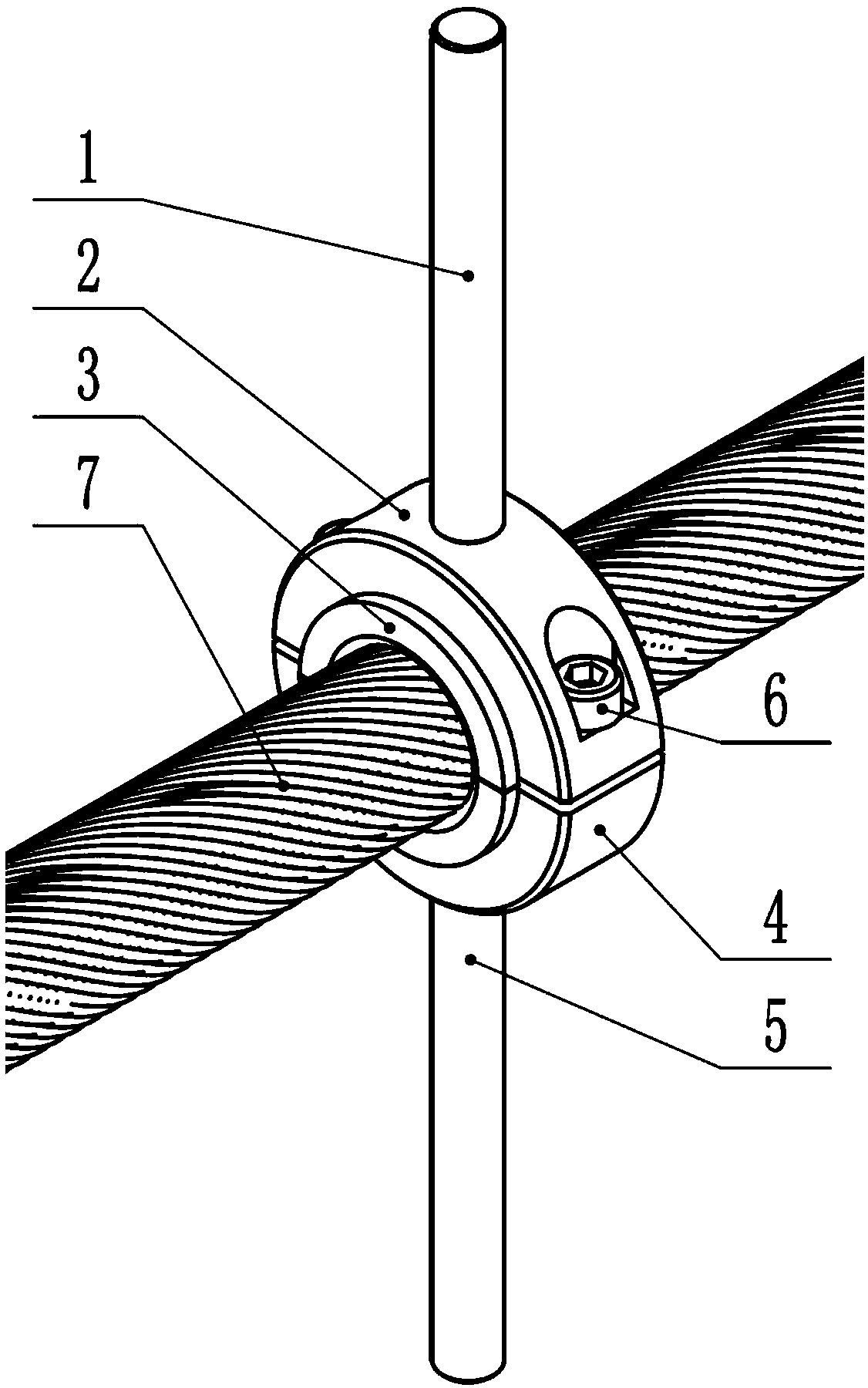

[0023] Such as figure 1 , 2 , 3, the present invention proposes a device for resetting the spiral armored steel wire, which can easily and efficiently restore the scattered armored steel wire to its original state without damaging the surface coating of the steel wire. Such as figure 1 As shown, the device includes: a first fixed half-ring 2 , a second fixed half-ring 4 , a fixing device 6 and two reset half-rings 3 .

[0024] The first fixed half ring 2 and the second fixed half ring 4 form a fixed ring structure with a circular cross section, and the two reset half rings 3 form a reset ring with a circular cross section, and the reset ring is sleeved on the fixed ring In the structure, a double ring structure with a cross section of double ring is formed; wherein, the first fixed half ring 2 and the second fixed half ring 4 are consolidated together by the fixing device 6 .

[0025] As one of the improvements of the above-mentioned technical solution, the reset ring is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com