Braiding method of aviation cable protection sleeve

A cable protection and protective sleeve technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of high price, high cost, and increased quality of carrier-based aircraft, reducing weight, reducing use, and anti-wave shielding. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

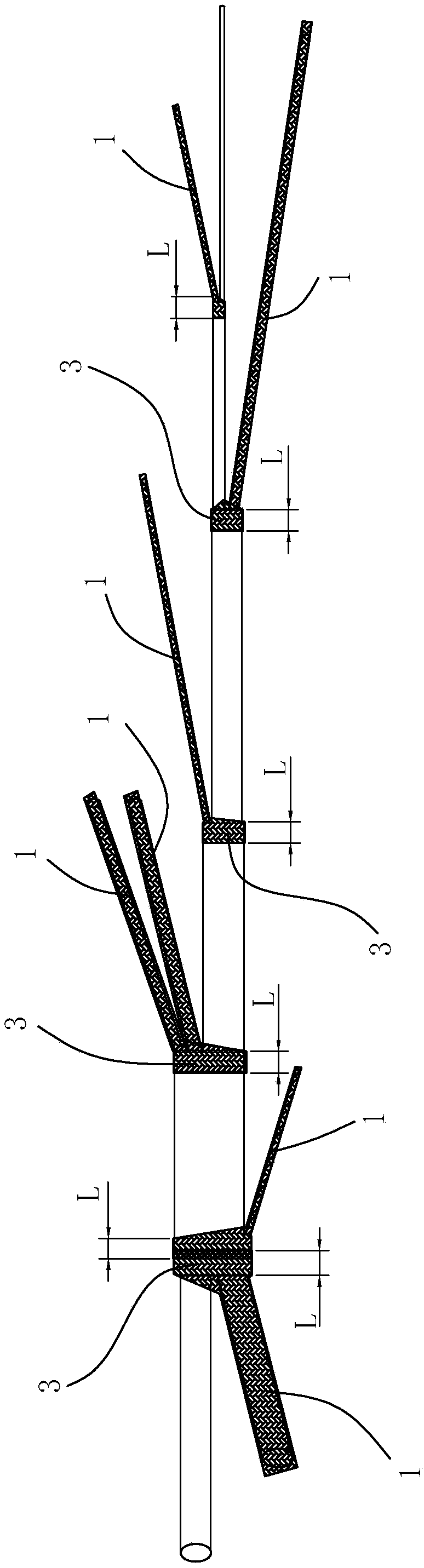

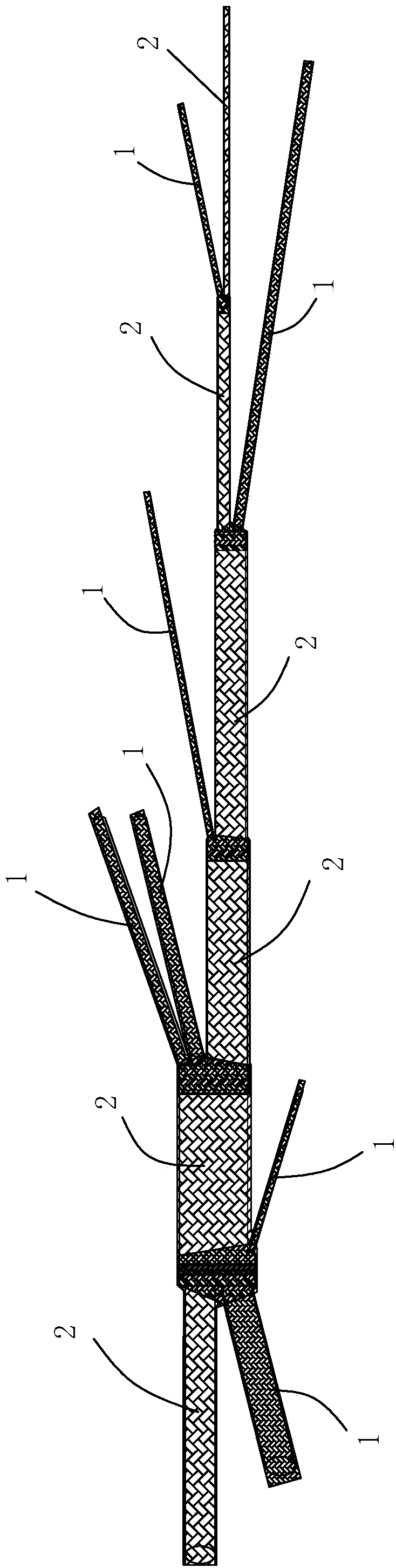

[0020] Such as Figure 1 to Figure 3 As shown, the weaving method of a kind of aviation cable protective sheath of the present embodiment comprises the following steps:

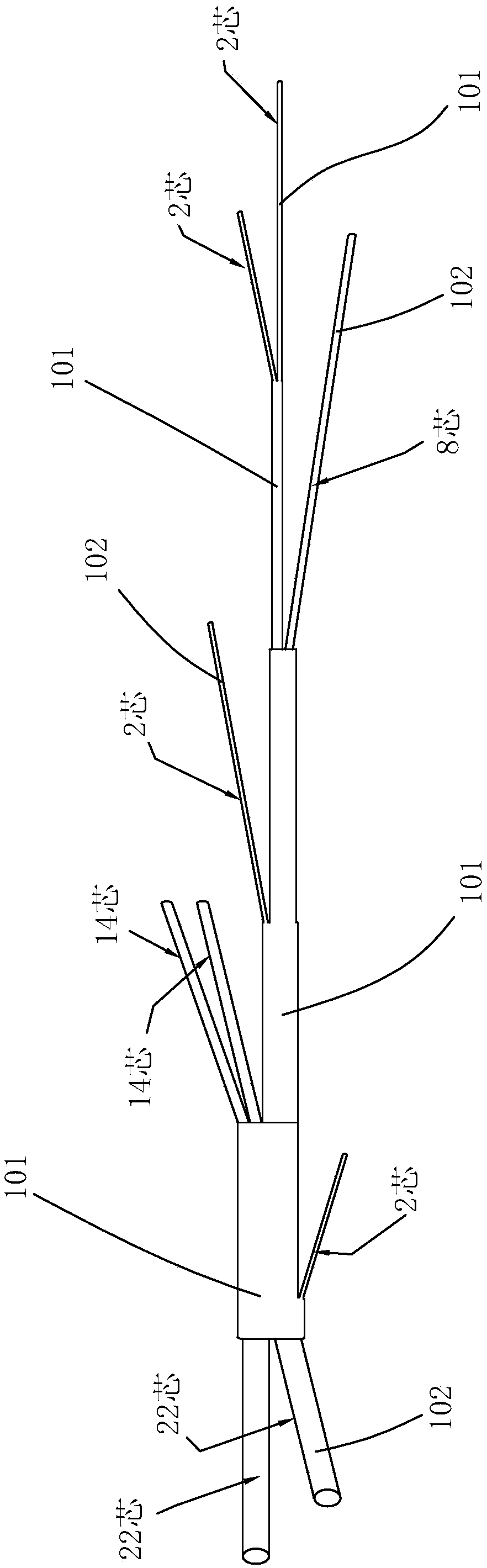

[0021] Step 1, wiring: according to the requirements of the design drawings, select the wires of the corresponding type and length, and arrange the multiple wires into the main line 101 and a number of branch sections 102 according to the requirements of the design drawings, and organize them neatly; because in the carrier aircraft The location of the general control room, the executive components, and the location of the wiring have been determined during the design, so it is only necessary to wire the wiring according to the requirements of the design drawings (attached figure 1 In , each branch section has corresponding execution parts, and the number of wires contained in each br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com