Electric hair dryer

The technology of a hair dryer and a hair dryer, which is applied to clothing, hairdressing equipment, hair drying devices, etc., can solve the problems such as the inability to further increase the wind speed, the inability to install large fan blades, and the laborious use, so as to improve the drying efficiency, speed, and efficiency. Fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

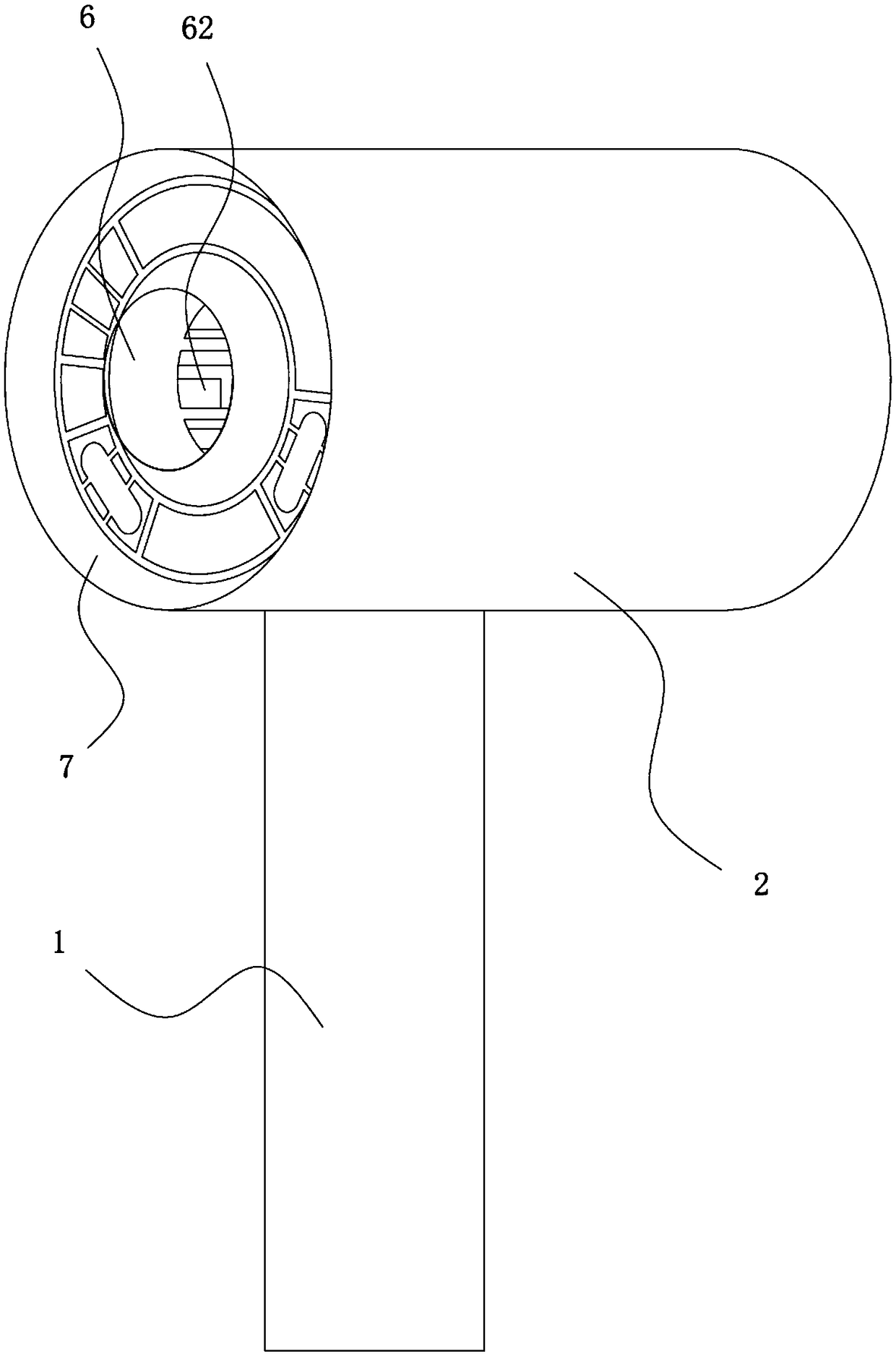

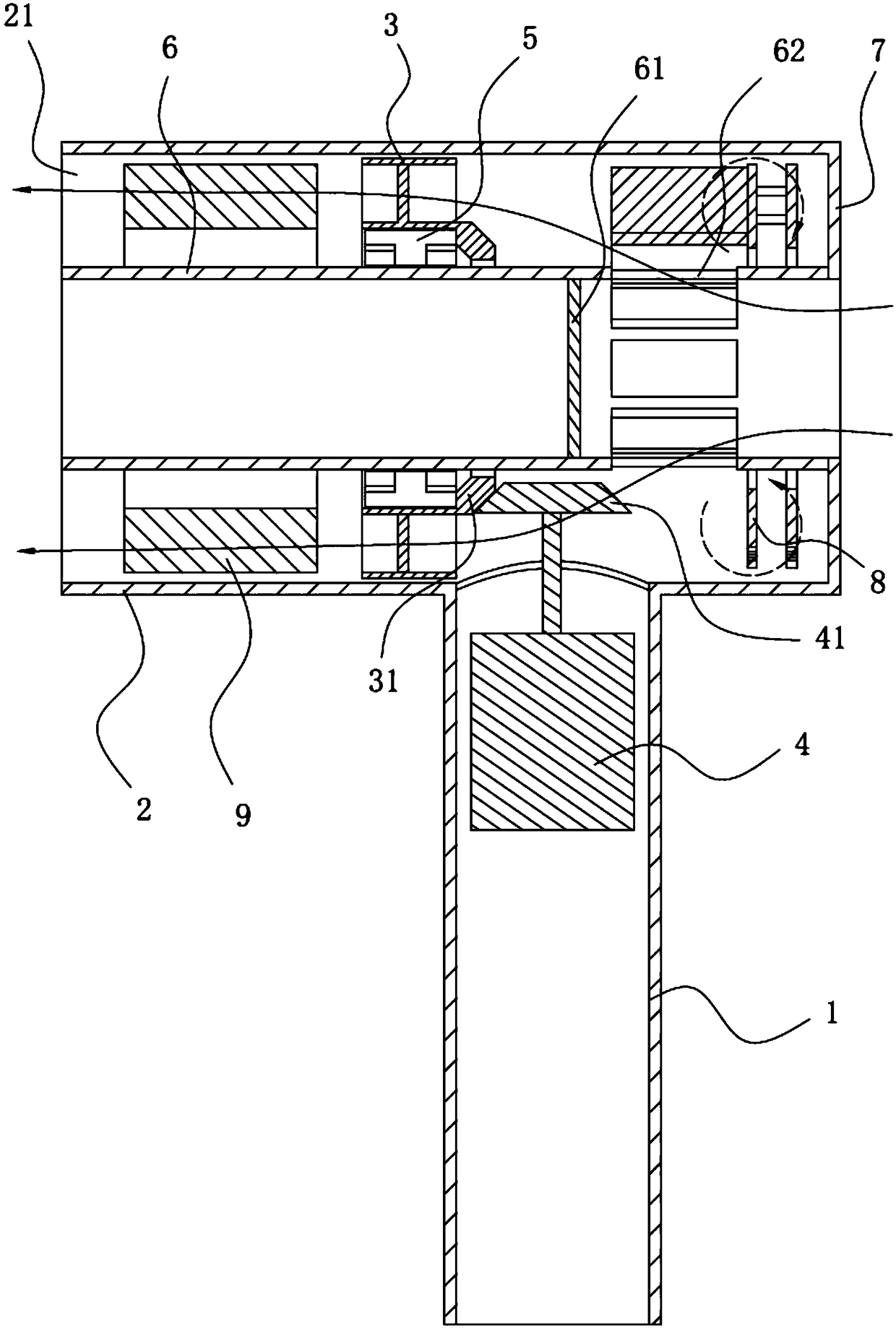

[0026] This embodiment discloses an electric hair dryer. like figure 1 As shown, the hair dryer includes a handle 1 and a blower 2 which are connected internally, and an inner cavity pipe 6 is sleeved on the inner side of the blower 2, and the end of the air inlet side of the blower 2 and the air inlet section of the inner cavity pipe 6 are An annular tailgate 7 is connected between the ends. An air inlet 62 is provided on the side wall of the inner tube 6 close to the air inlet, and the air flow passes through the air inlet of the inner tube 6 and the air inlet 62 successively and then enters the hair dryer.

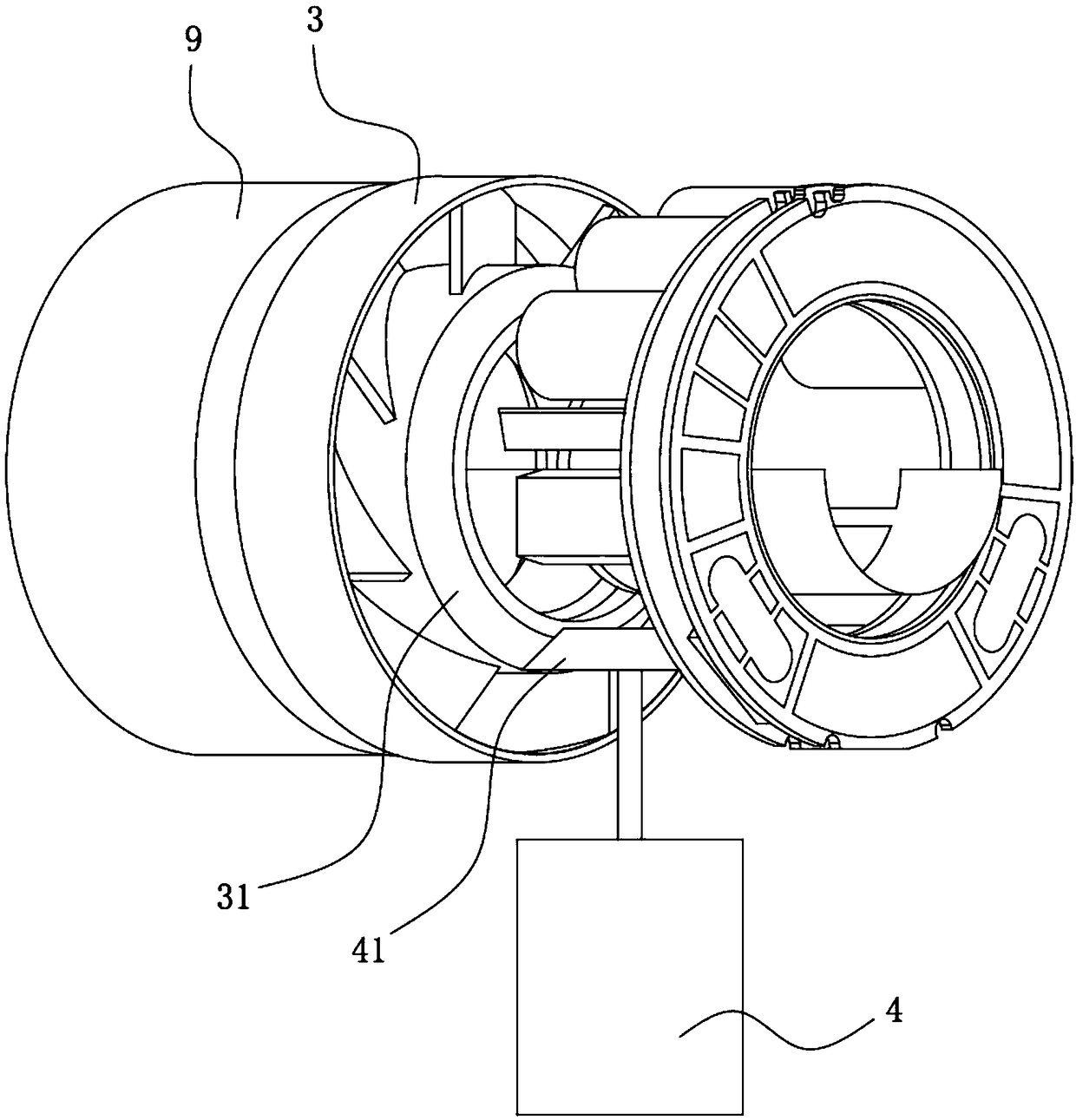

[0027] like figure 2 and image 3 As shown, fan blades 3 and heating wires 9 are sequentially arranged in the fan cylinder 2 along the blowing direction, the fan blades 3 are ring-shaped fan blades with bearings 5 pierced in the middle, and the inner cavity tube 6 is pierced in the middle of the bearings 5; the handle 1 is provided with a motor 4 . The output en...

Embodiment 2

[0036] This embodiment discloses an electric hair dryer, the structure of which is basically the same as that of Embodiment 1. The difference is that: if Figure 5 As shown, a worm 45 is provided at the output end of the motor 4, and a worm wheel 35 meshing with the worm 45 is provided on the fan blade 3, and the axis of the worm is perpendicular to or forms a certain angle with the axis of the worm wheel. The motor 4 drives the worm 45 to rotate around the vertical axis, and the worm 45 drives the worm wheel 35 to rotate around the horizontal axis, so as to achieve the same motion effect of driving the fan blade 3 as in the first embodiment.

[0037] The tooth of worm gear 35 can be arranged on the outer wall of fan blade 3 (as Figure 5 a) or on the side wall (such as Figure 5 As shown in b), it does not affect the engagement with the worm, and only needs to change the installation position of the worm 45 accordingly.

Embodiment 3

[0039] This embodiment discloses an electric hair dryer, the structure of which is basically the same as that of Embodiment 1. The difference is that: the direction conversion part includes a motor universal joint and a fan blade universal joint connected by an inclined cross connector, the motor universal joint is arranged at the output end of the motor, and the fan blade universal joint is arranged at the fan blade on the axis of rotation.

[0040] The output end of the motor rotates around the vertical line, and then drives the motor universal joint to rotate in the same direction; the motor universal joint drives the fan blade universal joint to rotate around the horizontal line or an axis close to the horizontal direction through the cross connector, and then drives the fan blade around the horizontal line Or an axis close to the horizontal direction can be rotated, so as to achieve the same motion effect of driving the fan blade to rotate as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com