Lanthanum-cerium co-doped titanium oxide material and preparation method based on mixed rare earth carbonate

A mixed rare earth and carbonate technology, applied in chemical instruments and methods, catalyst activation/preparation, nanotechnology for materials and surface science, etc. In order to achieve the effect of easy adjustment of doping ratio, low price, and reduced difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

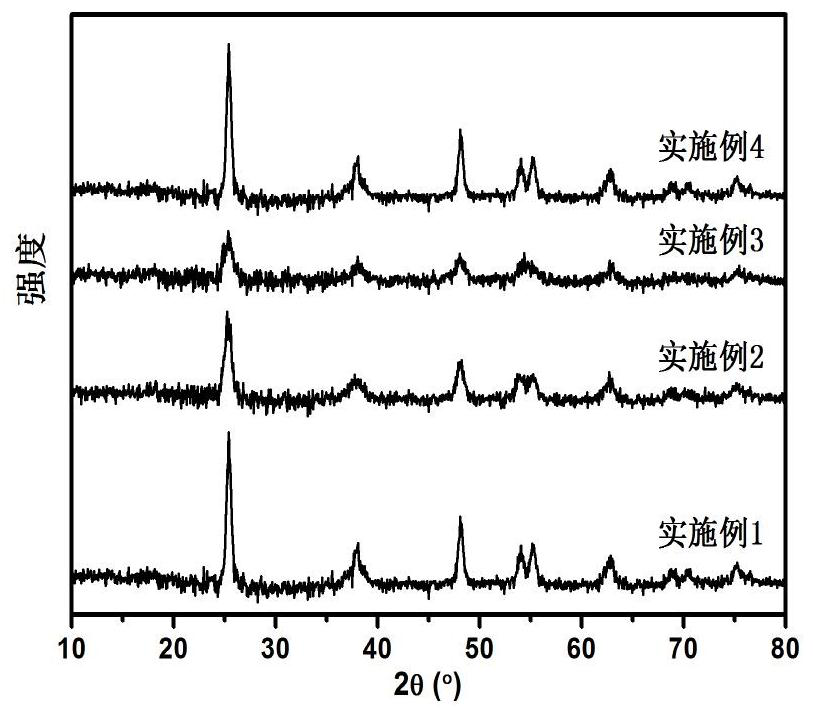

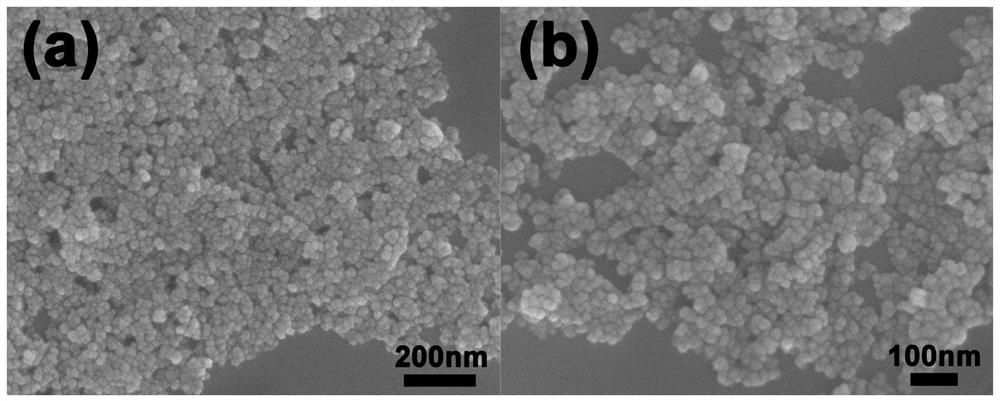

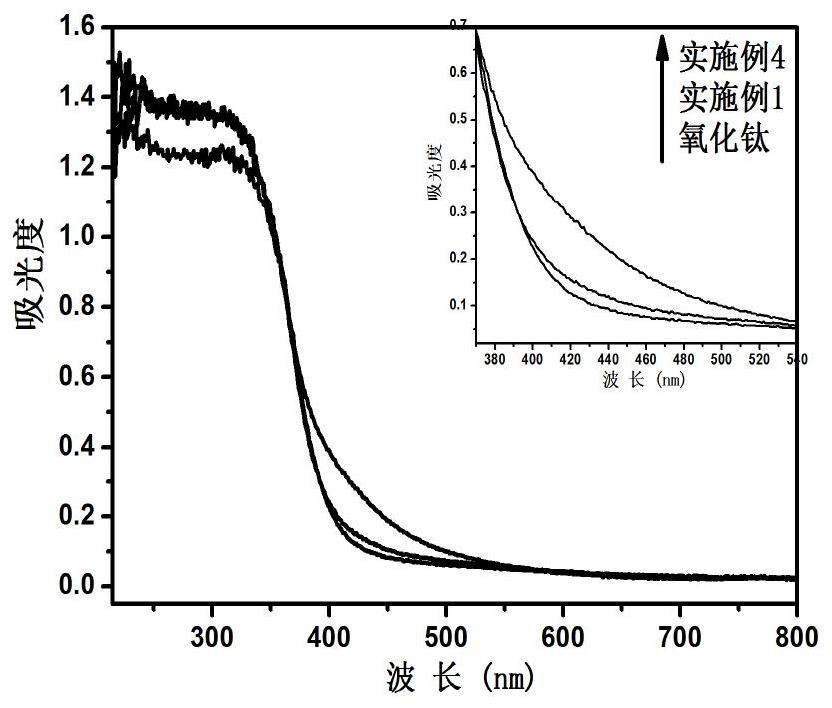

Embodiment 1

[0026] (1) Weigh 3.6 g of titanium sulfate, add 50 mL of distilled water to prepare a 0.3 mol / L titanium sulfate solution, and then magnetically stir for 30 min.

[0027] (2) Under the condition of stirring, mix the mixed rare earth carbonate solution into the precursor solution obtained in step (1), so that the lanthanum, cerium and TiO in the mixed solution 2 The molar percentages are 1.5% and 0.5%, respectively. After fully stirring, the pH value of the mixed liquid is adjusted to 1 with 2 mol / L sodium hydroxide solution, followed by magnetic stirring for 1 h.

[0028] (3) Place the emulsion obtained in step (2) in a water bath, and treat it in a water bath for 5 hours at a constant temperature of 90° C. under magnetic stirring conditions. After cooling, the emulsion was centrifuged several times to remove free CO 3 2- , SO 4 2- ions, the resulting white precipitate was dried at 80°C for 3 hours, and the powder sample obtained after grinding was calcined in a muffle fur...

Embodiment 2

[0030] (1) Weigh 1.6 g of titanyl sulfate, add 50 mL of distilled water to prepare a 0.2 mol / L titanium sulfate solution, and then magnetically stir for 30 min.

[0031](2) Under the condition of stirring, mix the mixed rare earth carbonate solution into the precursor solution obtained in step (1), so that the lanthanum, cerium and TiO in the mixed solution 2 The molar percentages of the mixtures were 1% and 1%, respectively. After fully stirring, the pH value of the mixed liquid was adjusted to 3 with 2mol / L ammonia solution, followed by magnetic stirring for 2h.

[0032] (3) Place the emulsion obtained in step (2) in a water bath, and treat it in a water bath for 2 hours at a constant temperature of 60° C. under magnetic stirring conditions. After cooling, the emulsion was centrifuged several times to remove free CO 3 2- , SO 4 2- ions, the resulting white precipitate was dried at 100°C for 4 hours, and the powder obtained after grinding was calcined in a muffle furnace ...

Embodiment 3

[0034] (1) Weigh 8 g of titanyl sulfate, add 50 mL of distilled water to prepare a 1 mol / L titanium sulfate solution, and then magnetically stir for 30 min.

[0035] (2) Under the condition of stirring, mix the mixed rare earth carbonate solution into the precursor solution obtained in step (1), so that the lanthanum, cerium and TiO in the mixed solution 2 The molar percentages of the mixtures were 3% and 2%, respectively. After fully stirring, the pH value of the mixed liquid was adjusted to 5 with 2mol / L ammonia solution, followed by magnetic stirring for 3h.

[0036] (3) Place the emulsion obtained in step (2) in a water bath, and treat it in a water bath for 8 hours at a constant temperature of 30°C under magnetic stirring. After cooling, the emulsion was centrifuged several times to remove free CO 3 2- , SO 4 2- ions, the resulting white precipitate was dried at 120°C for 5 hours, and the powder obtained after grinding was calcined in a muffle furnace at 700°C for 4 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com