Gantry type truss mechanical arm

A manipulator and gantry-type technology, applied in the field of manipulators, can solve the problems of large deflection, large deviation and low precision, and achieve the effects of reducing truss deformation, improving motion accuracy and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

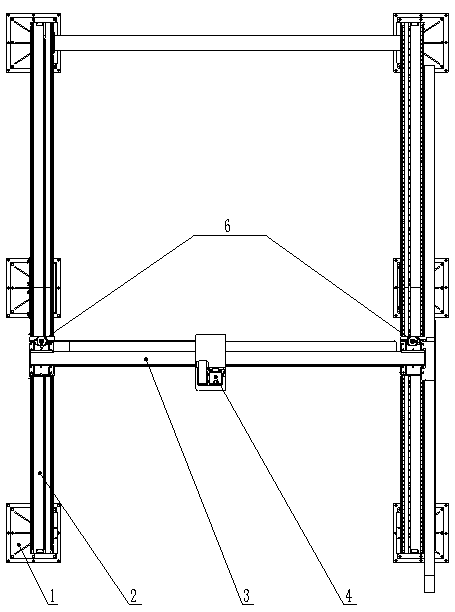

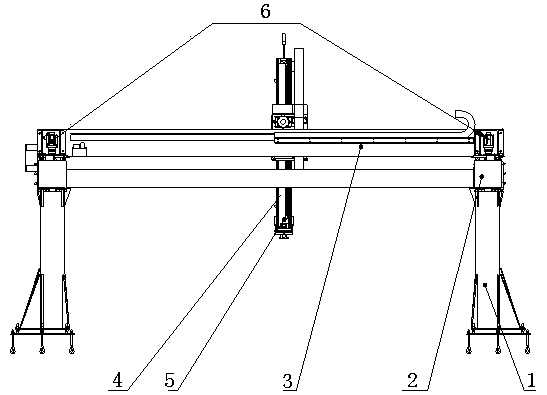

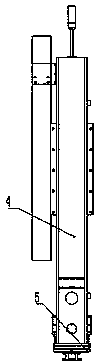

[0020] See figure 1 — image 3 , the gantry-type truss manipulator provided by the present invention includes a truss provided with two parallel X-axis beams 2 as rails through a column 1, and a truss that can move back and forth across the two parallel X-axis beams 2 as a mobile The Y-axis beam 3 of the beam, the Z-axis beam 4 as a vertical beam that is vertically arranged on the Y-axis beam 3 and moves left and right, up and down, the rotating device 5 arranged at the lower end of the Z-axis beam 4, and the The lower end of the rotating device 5 is used to reserve connecting flanges for clamping various gripping fixtures, and the two ends of the Y-axis beam 3 are respectively provided with independent walking devices to travel synchronously along the X-axis beam 2; One end of the axle beam 3 is fixed on the traveling device, and the other end is movably matched with the traveling device at this end in the axial direction of the beam.

[0021] More specifically: the truss c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com