Cement brick making machine

A brick making machine and cement technology, applied in the direction of manufacturing tools, supply devices, unloading devices, etc., can solve the problems of heavy weight and unchanged wiring, and achieve the effects of saving operating costs, preventing splashing, and slowing down impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

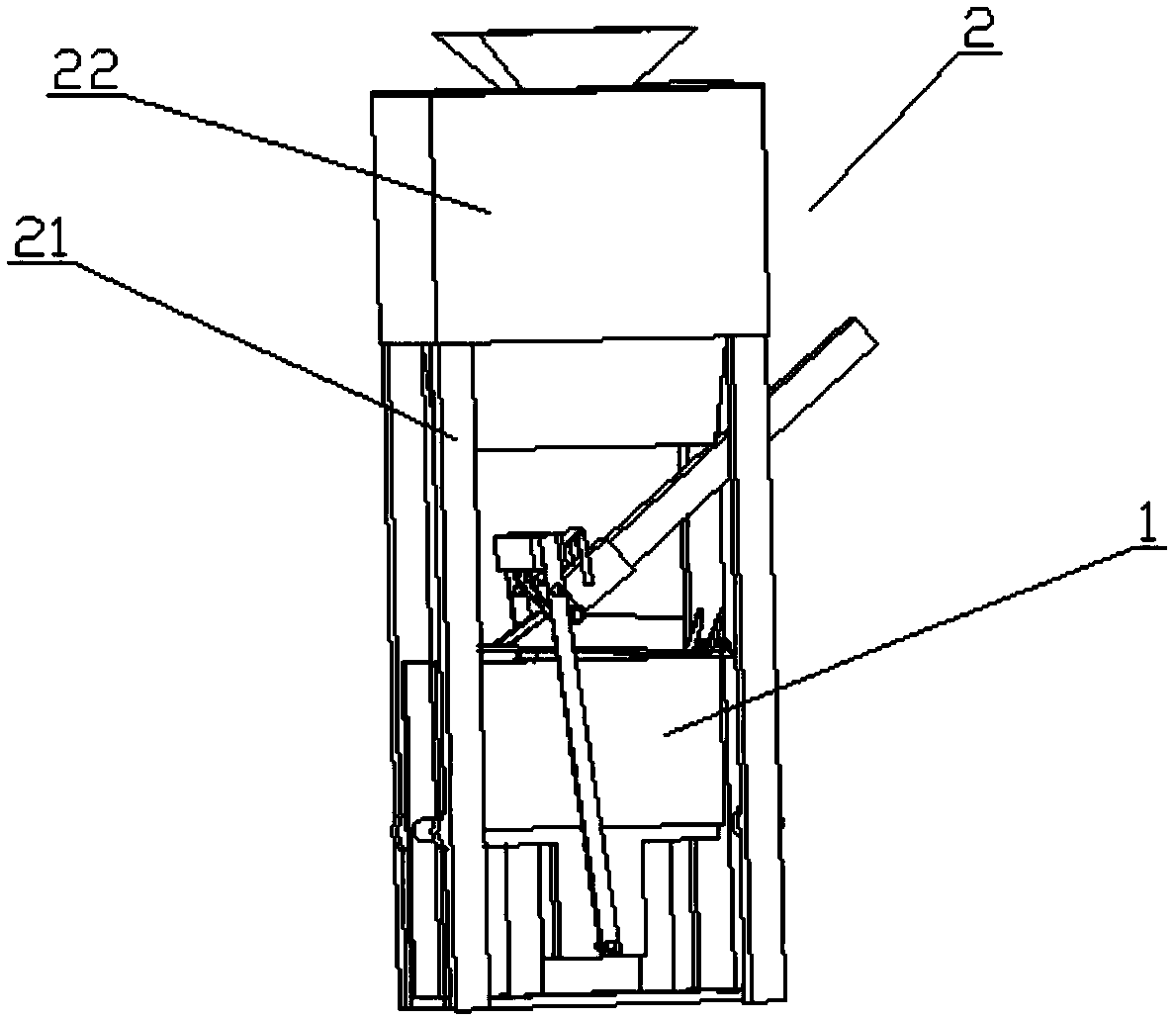

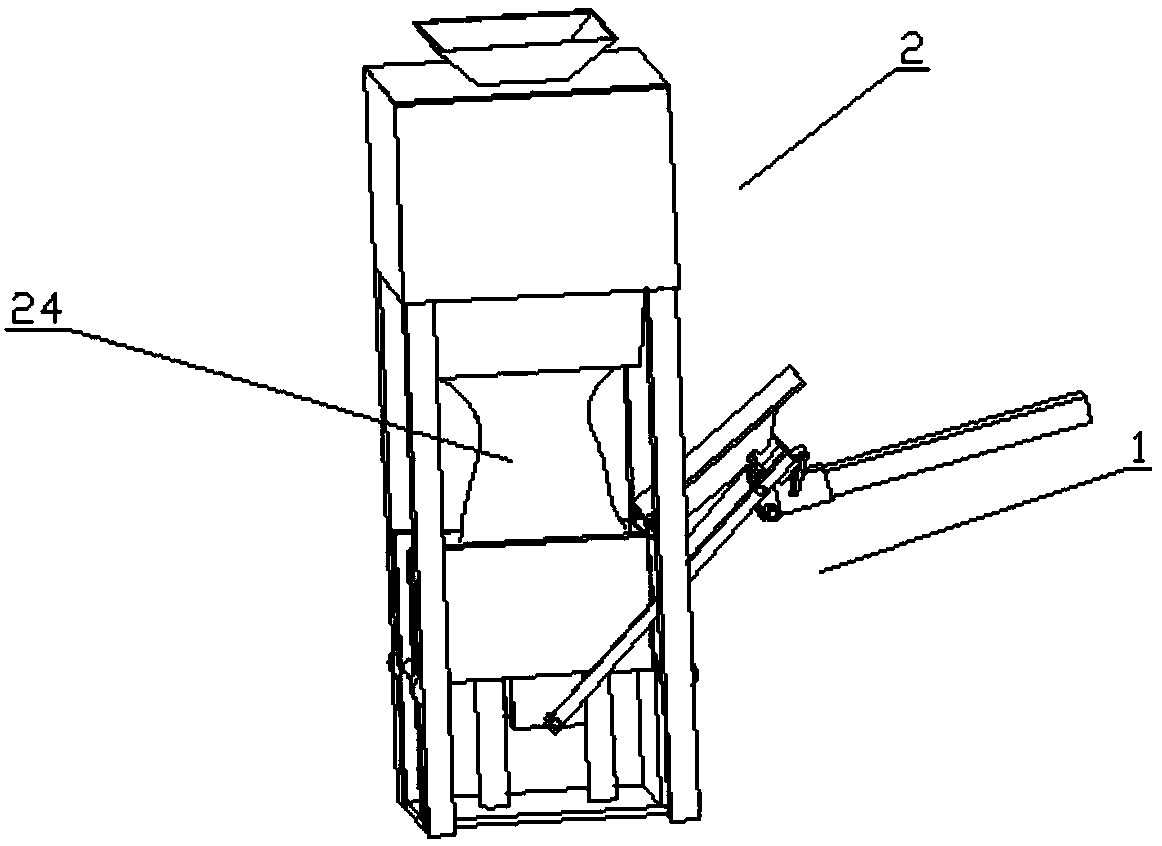

[0030] see Figure 1 to Figure 10 , the present invention is: a cement brick making machine, comprising a brick making device 1 and a feeding device 2, and the feeding device 2 is arranged above the brick making device 1;

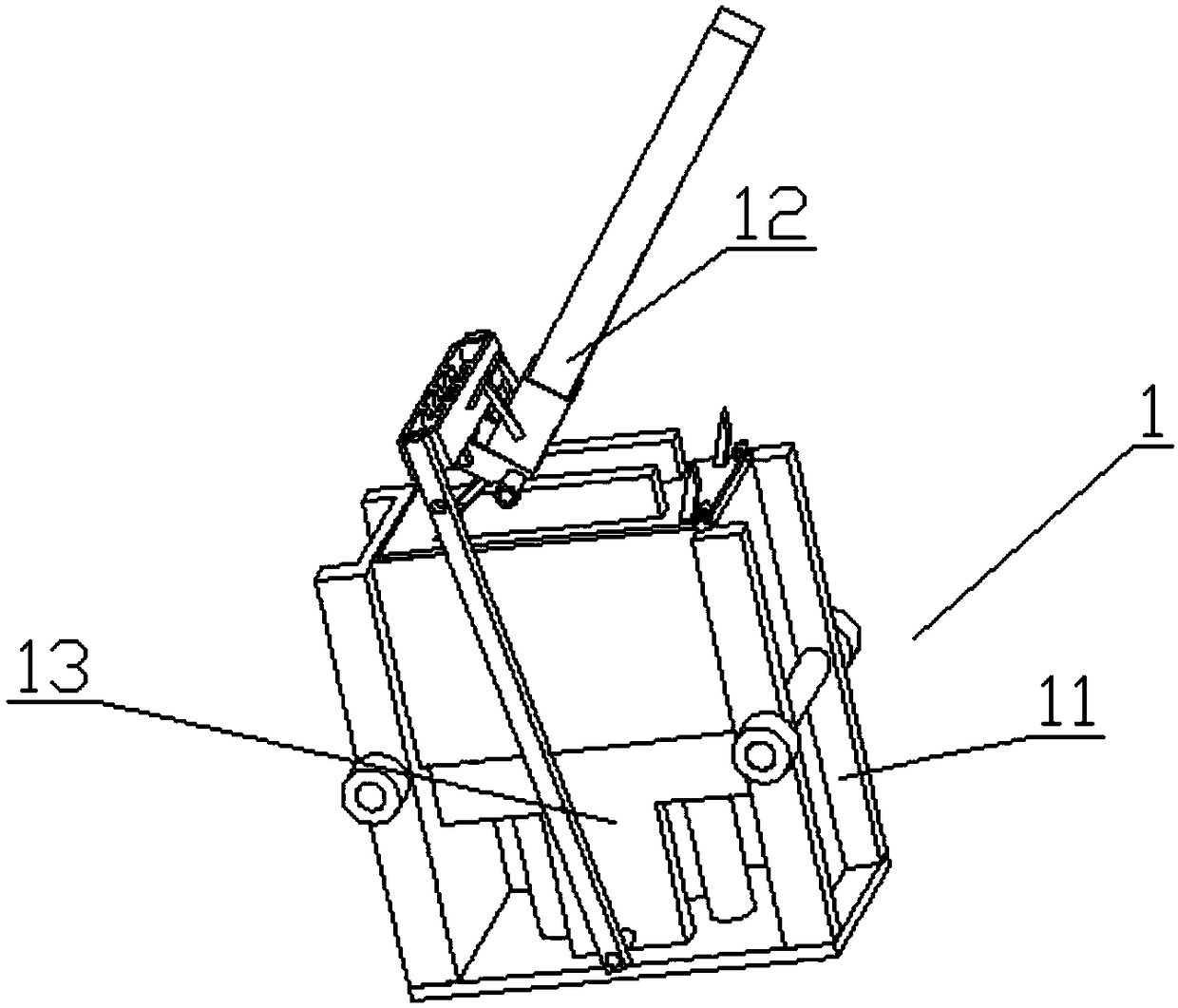

[0031] The brick-making device 1 includes a brick-making mold 11, an opening and closing mechanism 12, and an ejection mechanism 13. One end of the opening and closing mechanism 12 is connected to the brick-making mold 11 to drive the brick-making mold 11 to perform opening and closing movement, and the other end is connected to the ejection mechanism 13. , to drive the ejection mechanism 13 to move up and down;

[0032] The unloading device 2 includes a support frame 21, the support frame 21 is provided with a housing 22, the upper end of the housing 22 is provided with a feed port, the lower end of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap