A car rear spring seat installation structure

A technology of rear spring seat and installation structure, applied in elastic suspension, vehicle parts, transportation and packaging, etc., can solve the problems that the load can only be digested by itself, the service life is reduced, and the strength in the Y direction is not improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

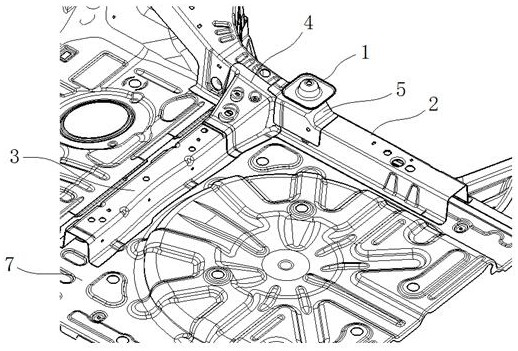

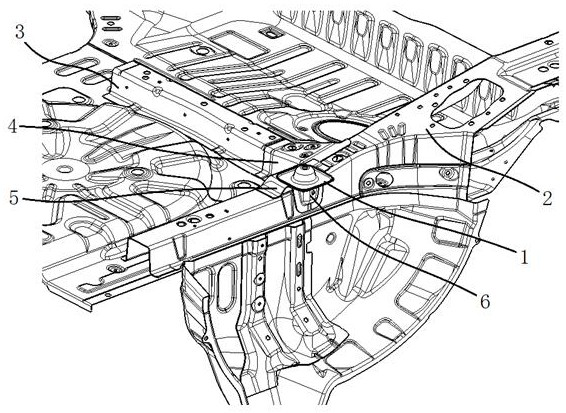

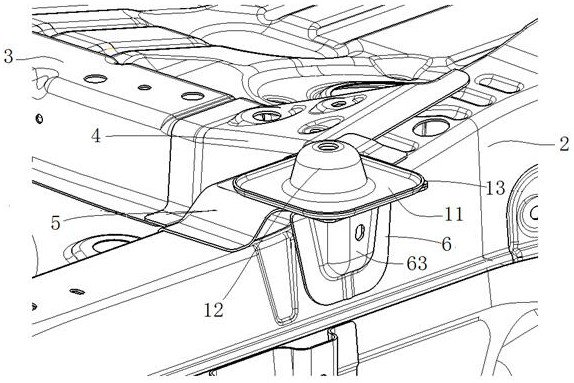

[0021] Such as figure 1 , 2 As shown, the present embodiment proposes a rear spring seat installation structure of an automobile, which specifically includes a spring seat 1, a rear longitudinal beam 2, a rear beam 3, a transverse beam connecting plate 4, a first bracket 5 and a second bracket 6, wherein : the rear longitudinal beam 2 and the rear cross beam 3 are all fixed on the rear floor 7 of the automobile, and the rear longitudinal beam 2 and the rear cross beam 3 are vertically arranged. The cross-section of the longitudinal beam connecting plate 4 is roughly in an inverted U shape, and the outer end of the transverse and longitudinal beam connecting plate 4 is provided with a continuous flange 41, and the flange 41 is fixedly connected with the rear longitudinal beam 2 by welding. The inner end of the beam connection plate 4 is sleeved on the rear cross beam 3 and welded and fixed with the rear cross beam 3; both sides of the cross and longitudinal beam connection pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com