Antistatic energetic material packaging box and stacking structure thereof

An anti-static, packing box technology, applied in packaging, transportation and packaging, rigid containers, etc., can solve problems such as potential safety hazards, and achieve the effects of ensuring safety, improving anti-static performance, and uniform and stable distribution of static-conducting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

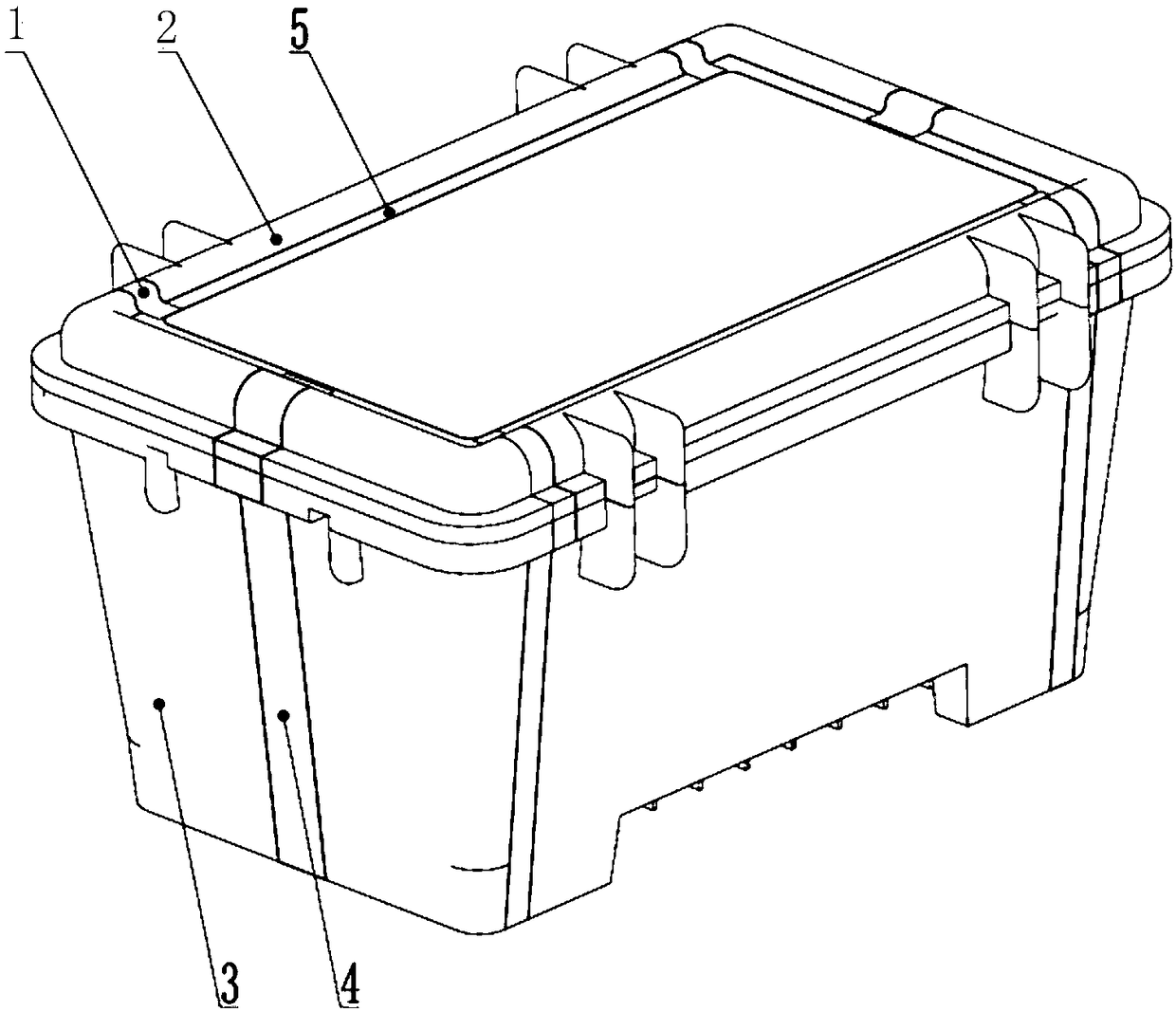

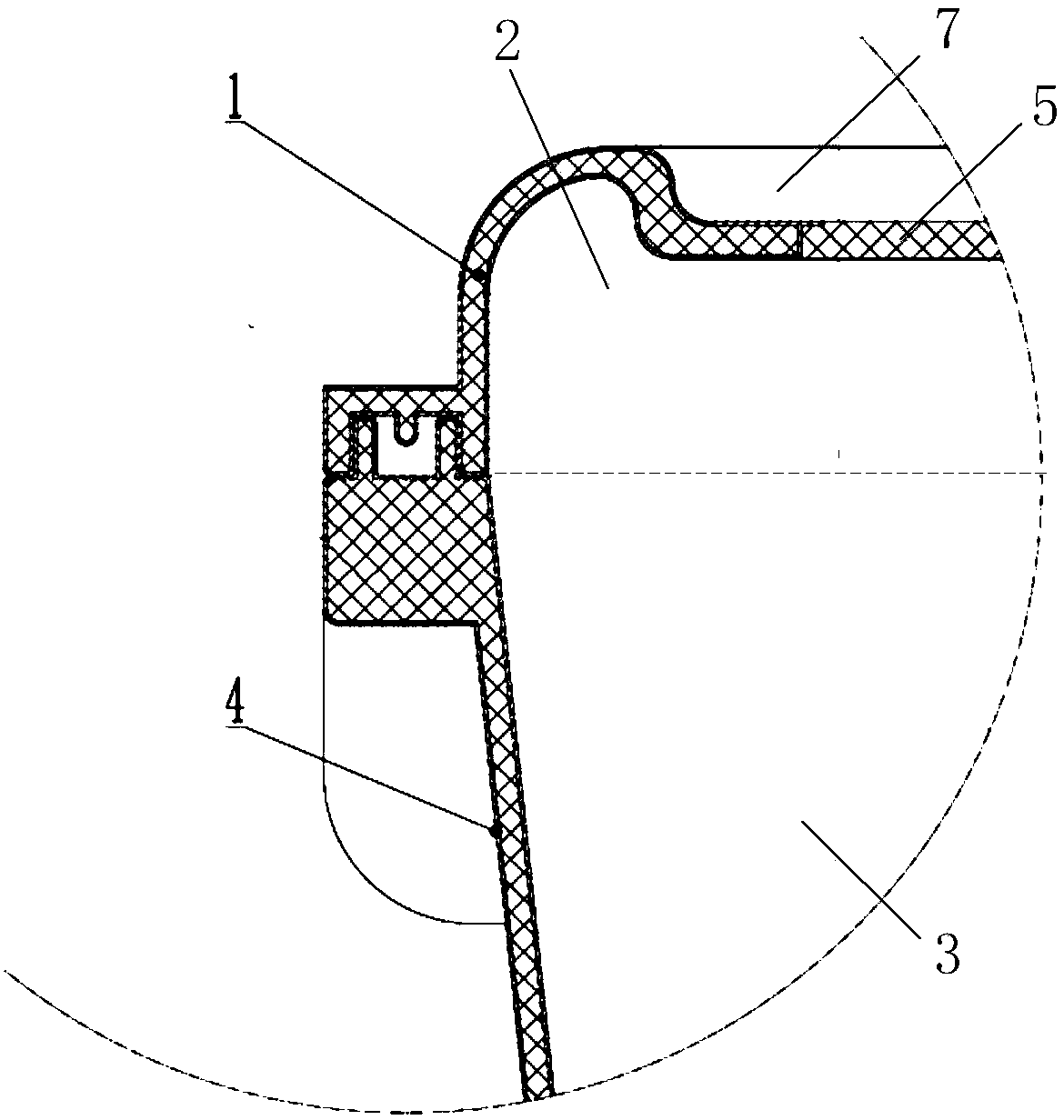

[0030] Such as Figure 1 to Figure 3 An anti-static packaging box containing energetic materials is shown, comprising a detachable box body 3 and a box cover 2. The outer surface of the box cover 2 is provided with a box cover conductive device 1, and the outer surface of the box body 3 is provided with a box body The conductive device 4 also includes a conductive plate 5 fixed on the outer surface of the box body 3 or / and the box cover 2. The conductive plate 5 is in conduction with the box body conductive device 4 or the box cover conductive device 1; when the box cover 2 When connected to the box body 3, the box cover conductive device 1 is in contact with the box body conductive device 4. The box conductive device 4 is directly grounded. The conductive plate 5 is in the shape of a box. Each side of the conductive plate 5 is connected to at least one box cover conductive device 1, and the conductive plate 5 is fixed on the top surface of the box cover 2; the box cover condu...

Embodiment 2

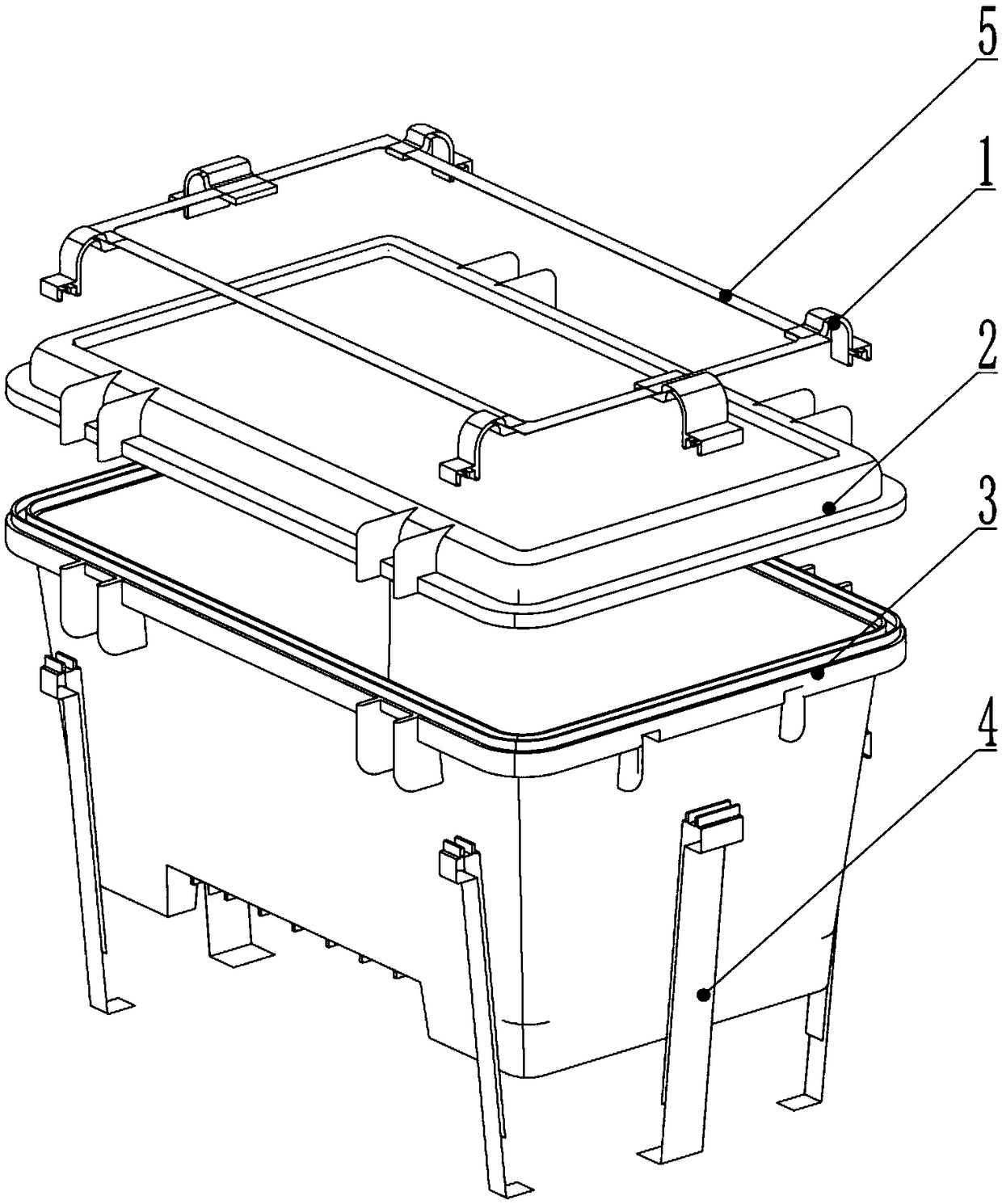

[0032] Such as Figure 4 The stacking structure of an antistatic packaging box for energetic materials is shown. Several antistatic packaging boxes for energetic materials are stacked on top of each other. Between two adjacent antistatic packaging boxes for energetic materials, the upper containing The conductive device 4 of the box body of the energy-containing anti-static packaging box is in contact with the conductive device 1 or / and the conductive plate 5 of the cover of the anti-static packaging box of the energy-containing material located below; it also includes a static discharge device 6 for grounding. The electrostatic discharge device 6 is in communication with the box body conductive device 4 of any energetic material antistatic packaging box. The upper surface of the box cover 2 is provided with a groove 7, and the bottom surface of the box body 3 matches the groove 7, and the box body 3 of the energy-containing material anti-static packaging box located above is pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com