Municipal road pipe-jacking construction security equipment and operation method thereof

A kind of safety equipment and municipal road technology, applied in the field of pipe jacking construction equipment on municipal roads, can solve problems such as falls, climbing fatigue, life-threatening, etc., and achieve the effects of improving safety factor, protecting personal safety, and reducing injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

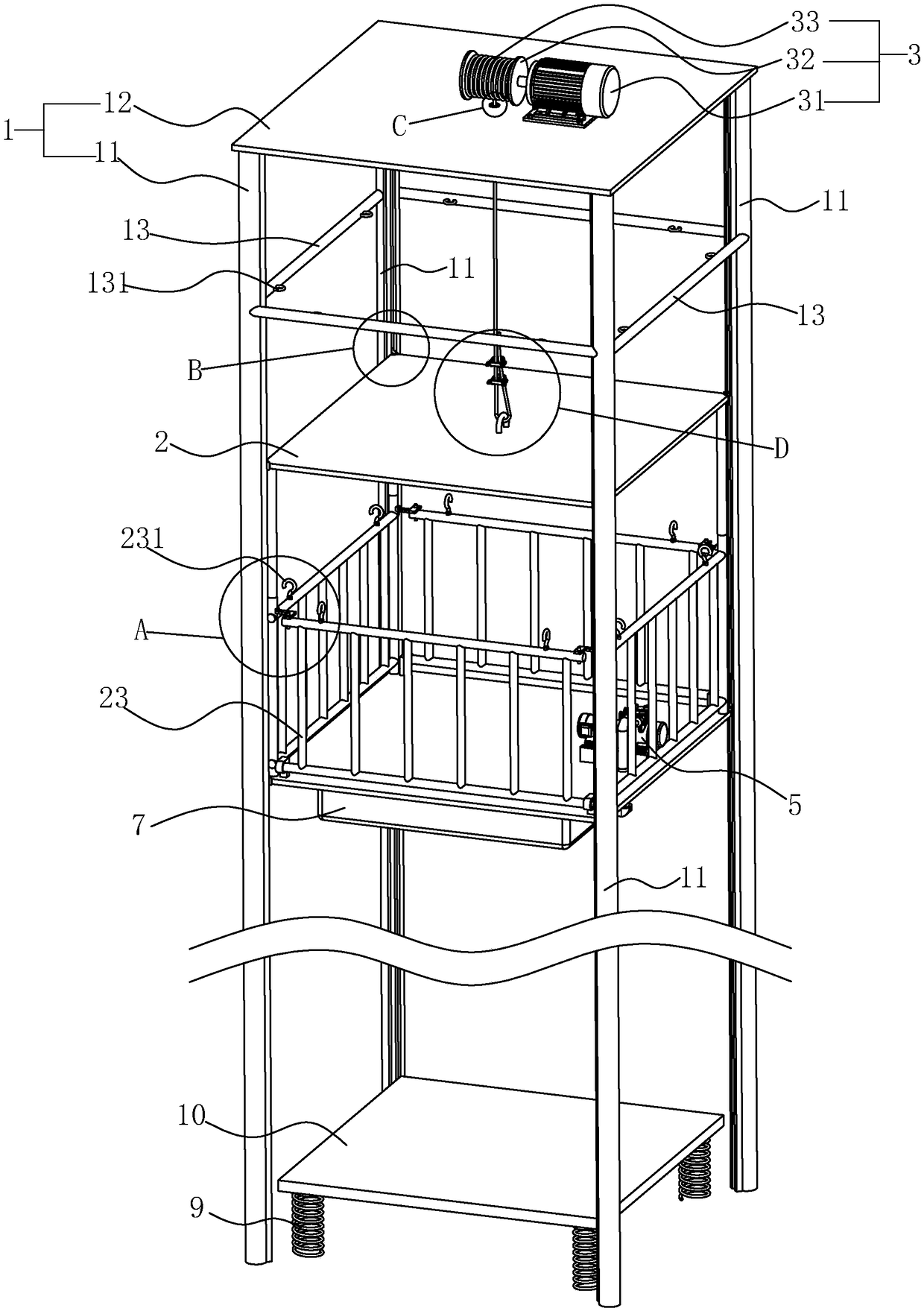

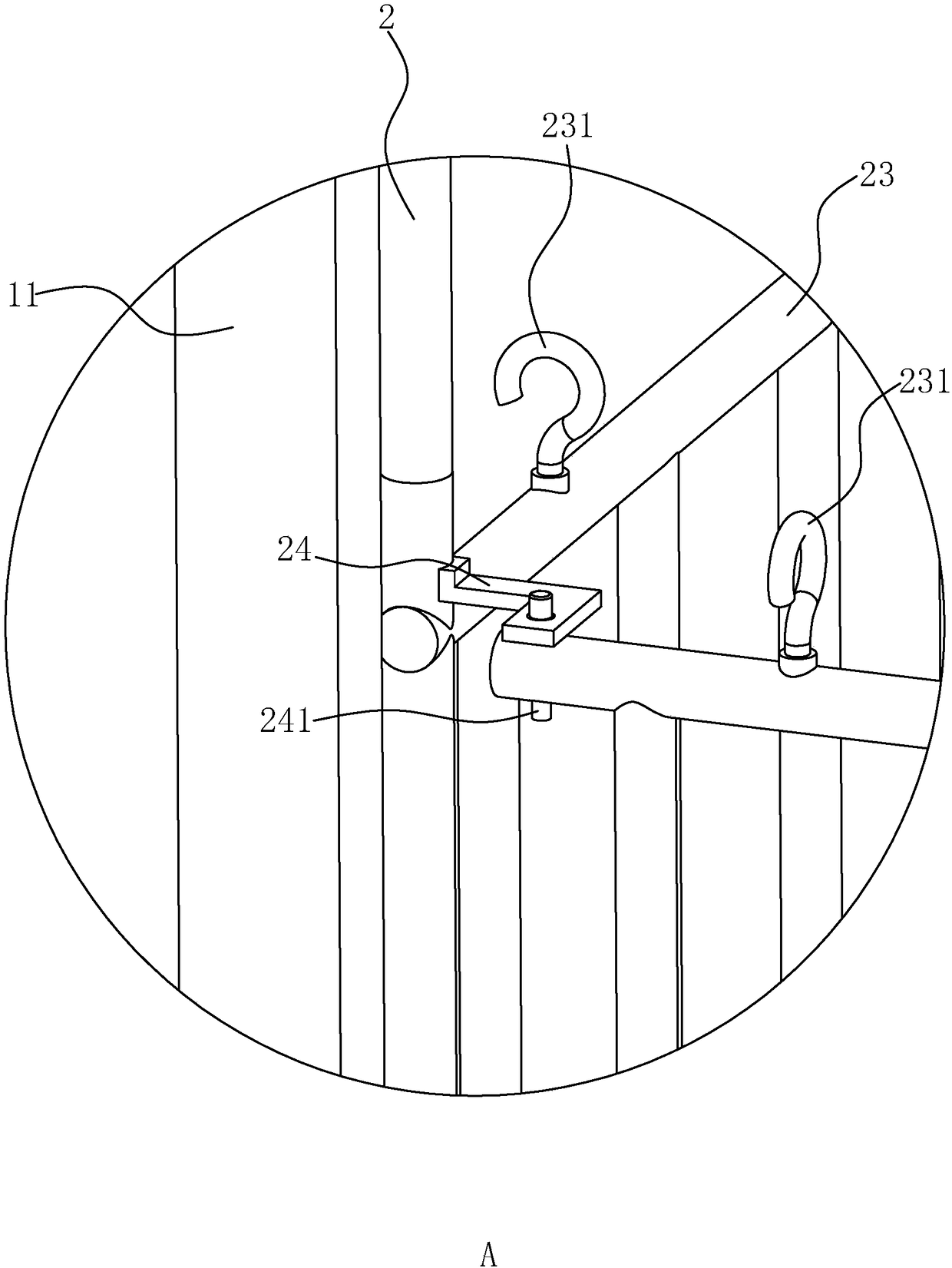

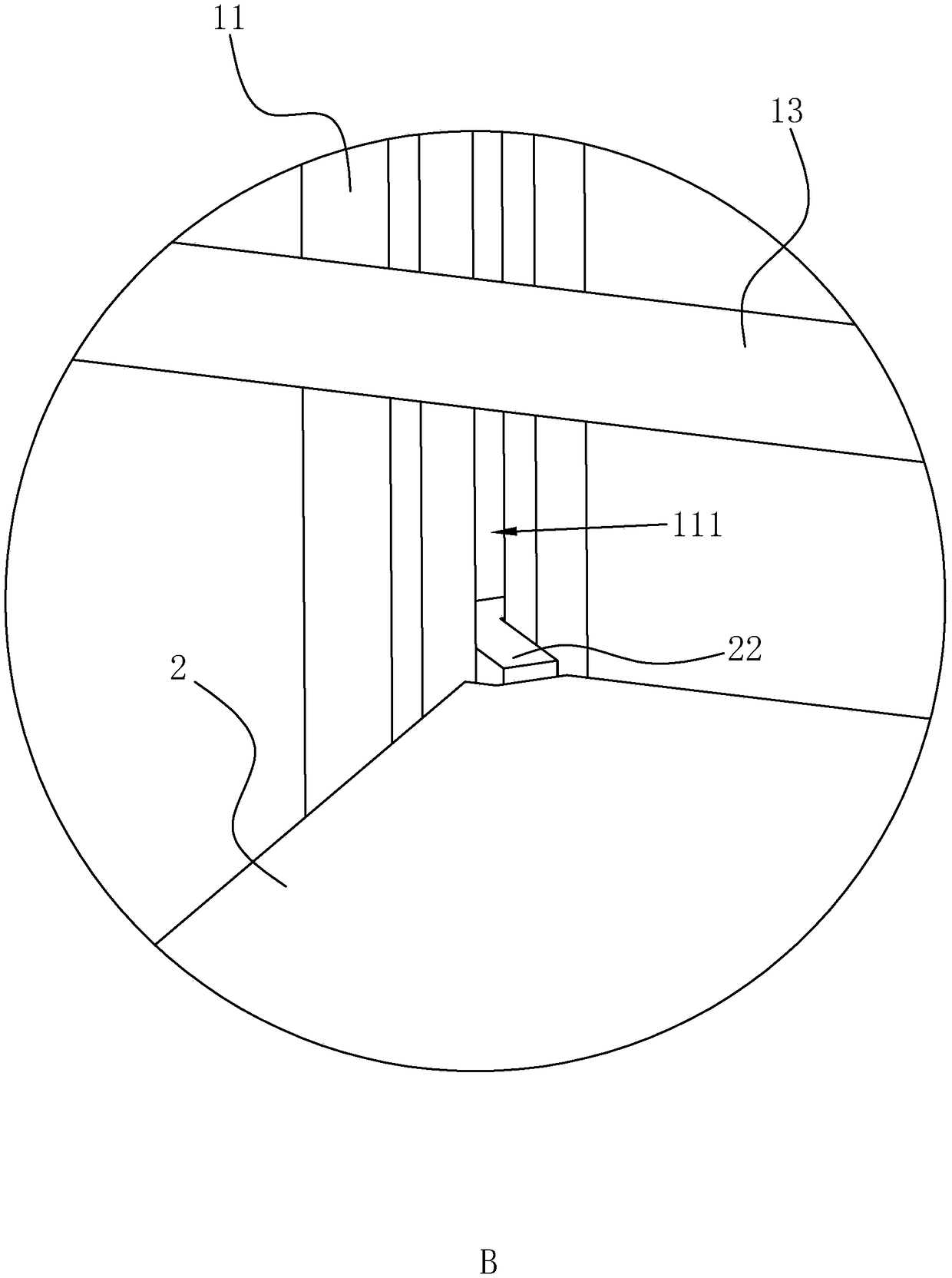

[0046] Such as figure 1 , 2 As shown, a municipal road pipe jacking construction safety equipment includes a sliding frame 1 arranged in a working pit and higher than the ground. The sliding frame 1 is composed of four columns 11 parallel to each other and a top plate 12 arranged at the top of the columns 11. A loading frame 2 is slidably arranged between the uprights 11, and the length of the section of the uprights 11 higher than the ground is longer than the height of the loading frame 2, and the surroundings of the loading frame 2 are provided with a fence 23 surrounding the loading frame 2, close to the ground side and The fence 23 on the side away from the ground is all opened and closed on the loading frame 2 , and the loading frame 2 is provided with a connecting plate 24 attached to the free end of the fence 23 , and a bolt 241 is inserted between the connecting plate 24 and the fence 23 .

[0047] When entering the loading frame 2, open the fence 23 close to the gro...

Embodiment 2

[0056] A method of operating safety equipment for pipe jacking construction on municipal roads, comprising the following steps:

[0057] Step 1. The operator first opens the fence 23 close to the ground side, enters the loading frame 2, then fits one side of the fence 23 to the connecting plate 24, and fixes the fence 23 with the bolt 241;

[0058] Step 2, start the air pump 5, let the air pump 5 inflate the air bag 7, and make the air bag 7 bulge;

[0059] Step 3, start the rotating motor 31, let the wire rope 33 begin to stretch and drive the loading frame 2 between the columns 11 to slide down into the working pit;

[0060] Step 4. When reaching the bottom of the working pit, turn off the rotating motor 31, remove the latch 241, and open the fence 23;

[0061] Step 5. When going up from the bottom of the working pit to the ground, enter the loading frame 2, start the rotating motor 31, and let the loading frame 2 rise to the top of the column 11;

[0062] Step 6: After ha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap