A kind of cement modified grinding aid containing mannitol and ethyl silicate and its preparation method and application

A cement modification and ethyl silicate technology, applied in the field of cement additives, can solve the problems of affecting the performance index of cement concrete, concrete engineering quality, poor compatibility between cement and concrete admixtures, affecting the effect of cement and admixtures, etc. , to improve the adaptability and construction performance, maintain volume stability, and reduce the water consumption of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

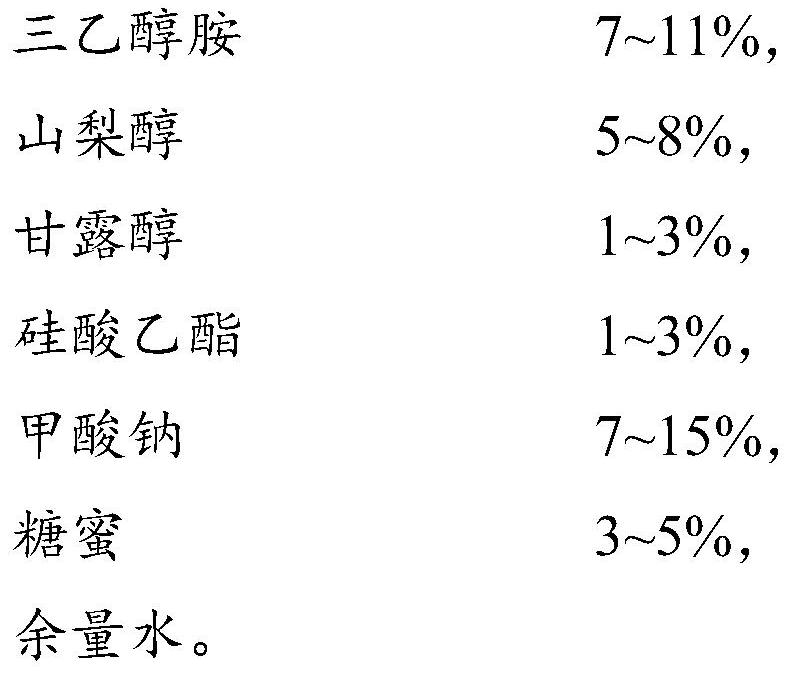

[0027] The present invention provides the preparation method of the modified cement grinding aid containing mannitol and ethyl silicate described in the above technical scheme, comprising the following steps:

[0028] (1) water and sodium formate are mixed to obtain sodium formate solution;

[0029] (2) the sodium formate solution obtained in step (1) is mixed with molasses to obtain a sodium formate-molasses mixed solution;

[0030] (3) mixing the sodium formate-molasses mixed solution obtained in step (2) with triethanolamine, sorbitol, mannitol, and ethyl silicate to obtain a cement modified grinding aid.

[0031] The present invention mixes water and sodium formate to obtain sodium formate solution. In the present invention, the mixing is preferably carried out under stirring. The present invention has no special requirements for the stirring method, and can be stirred according to technical means well known to those skilled in the art; the present invention has no specia...

Embodiment 1

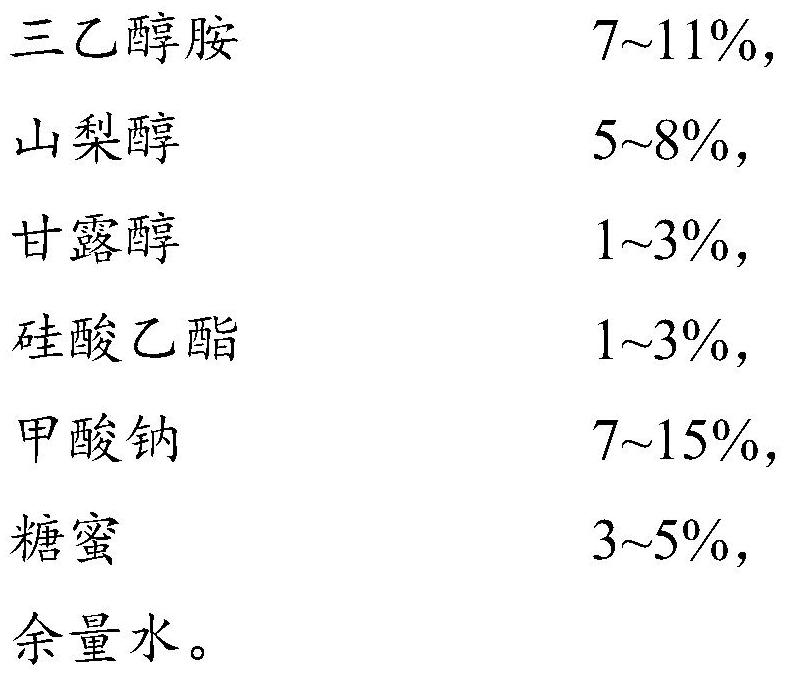

[0037] A cement modified grinding aid containing mannitol and ethyl silicate, comprising the following components in parts by mass: 7 parts of triethanolamine, 8 parts of sorbitol, 3 parts of mannitol, 1 part of ethyl silicate, and 15 parts of sodium formate , 3 parts of molasses and 63 parts of water.

Embodiment 2

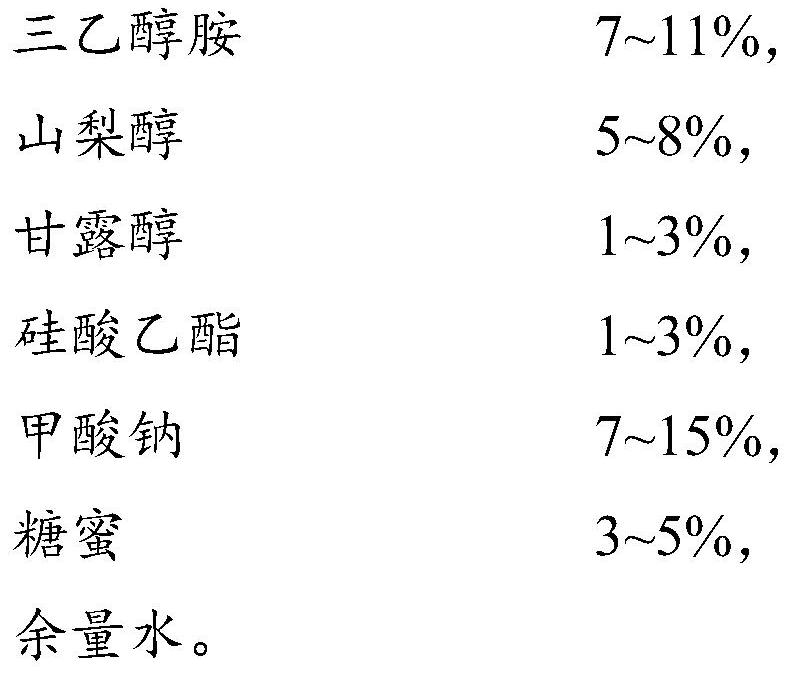

[0039] A cement-modified grinding aid containing mannitol and ethyl silicate, comprising the following components in parts by mass: 9 parts of triethanolamine, 6.5 parts of sorbitol, 2 parts of mannitol, 2 parts of ethyl silicate, and 11 parts of sodium formate , 4 parts of molasses and 65.5 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com