A colloid photonic crystal having high contrast and no crack and a preparing method thereof

A colloidal photonic crystal, high-contrast technology, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve the problem that the interaction force of monodisperse emulsion particles cannot be enhanced, particle cracking cannot be solved, and large-area crack-free preparation cannot be achieved. Photonic crystal and other problems, to achieve the effect of reducing color interference, mild preparation conditions, and enhancing interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

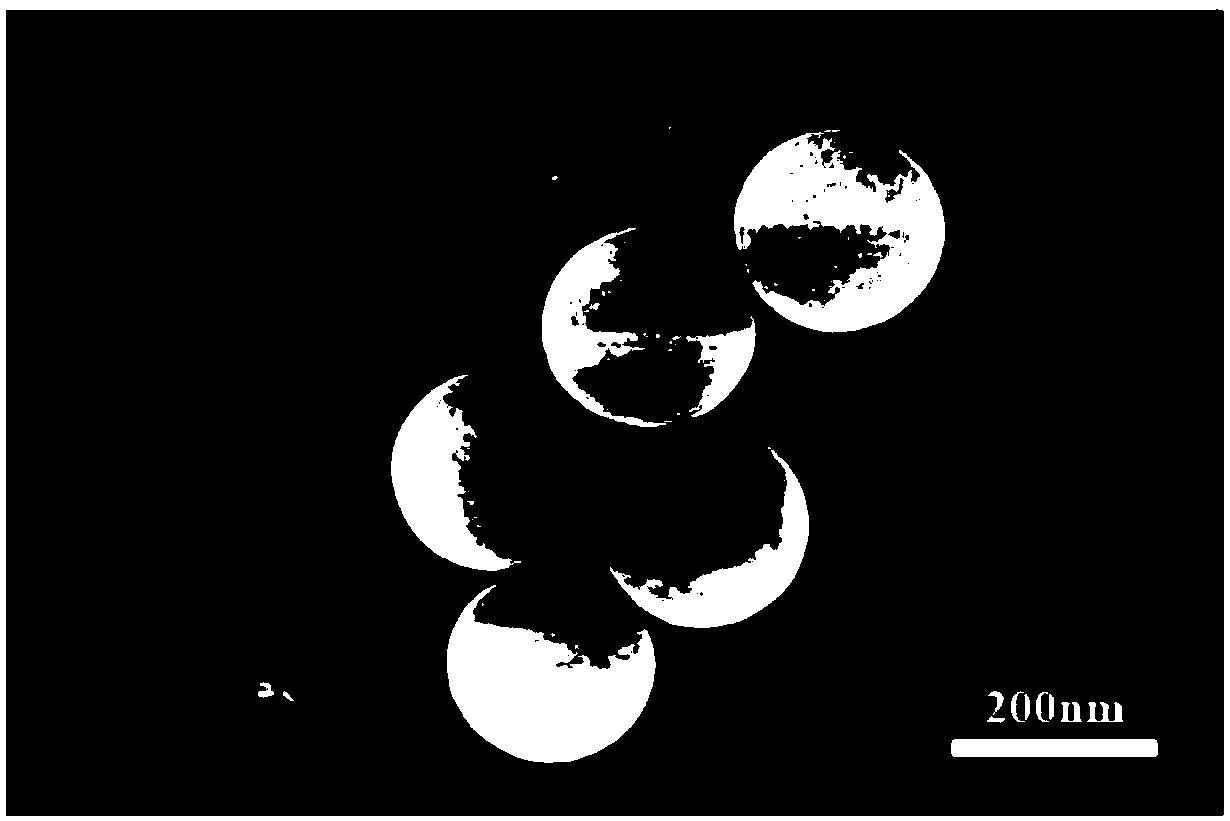

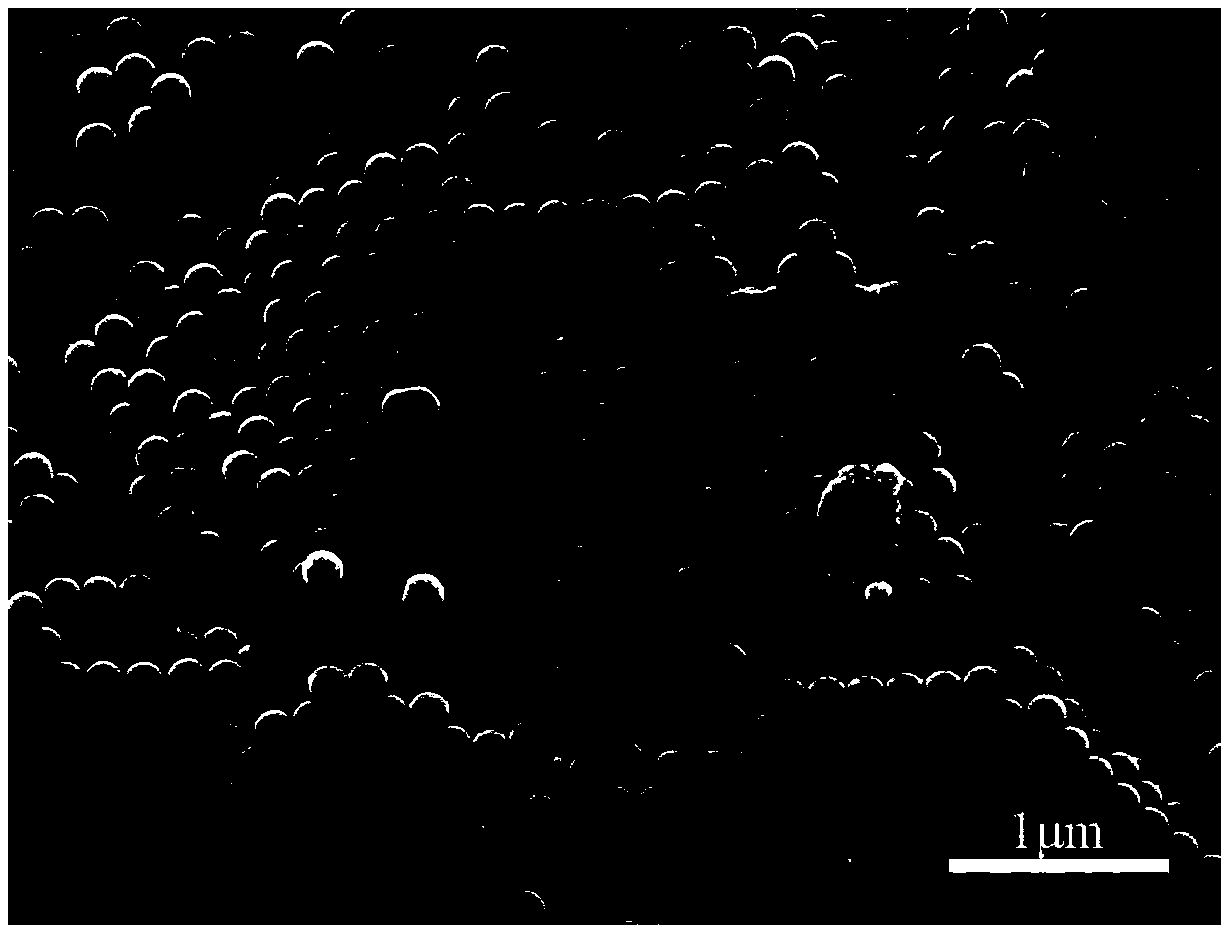

[0042] Step 1: In terms of parts by mass, mix 15 parts of styrene, 2 parts of ammonium persulfate, and 100 parts of water, stir to form a uniform solution, pass nitrogen to remove oxygen in the system, and place in a 75°C water bath to initiate polymerization ; After reacting for 10 hours, the reaction product was freeze-dried to obtain monodisperse polystyrene latex particles with a particle size of 210 nm;

[0043] Step 2: ultrasonically disperse monodisperse polystyrene latex particles with a particle size of 210 nm in water to form a monodisperse polystyrene emulsion with a mass fraction of 13 wt %;

[0044] Step 3: ultrasonically dispersing graphene in water to form a graphene dispersion with a mass fraction of 0.5 wt %;

[0045] Step 4: Mix the monodisperse polystyrene emulsion and the graphene dispersion with a particle size of 210nm uniformly at a volume ratio of 1.5:1 to obtain a mixed solution of the 210nm monodisperse polystyrene emulsion and the graphene dispersion...

Embodiment 2

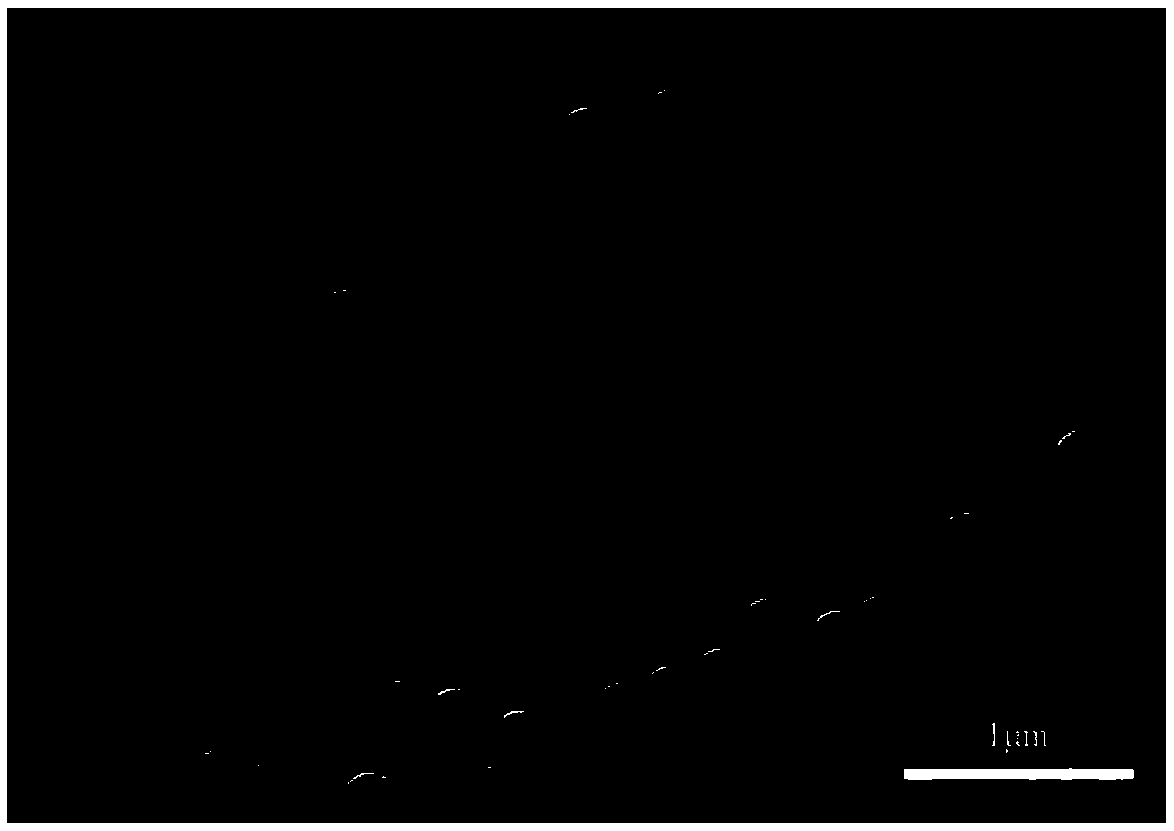

[0054] Step 1: In terms of parts by mass, mix 15 parts of styrene, 3 parts of acrylic acid, 3 parts of sodium persulfate, and 100 parts of water, stir to form a uniform solution, pass nitrogen to remove oxygen in the system, and place at 80°C Initiate polymerization in a water bath; react for 12 hours, freeze-dry the reaction product to obtain monodisperse polystyrene-acrylic acid latex particles with a particle size of 250 nm;

[0055] Step 2: ultrasonically disperse monodisperse polystyrene-acrylic latex particles with a particle size of 250 nm in ethanol to form an emulsion with a mass fraction of 10 wt %;

[0056] Step 3: ultrasonically dispersing carbon black in water to form a dispersion with a mass fraction of 1 wt %;

[0057] Step 4: Mix the monodisperse polystyrene-acrylic emulsion and the carbon black dispersion evenly at a volume ratio of 1:1 to obtain a mixture of 250nm monodisperse polystyrene-acrylic emulsion and carbon black dispersion. Apply it on a glass shee...

Embodiment 3

[0060] Step 1: In terms of parts by mass, mix 18 parts of styrene, 3 parts of methacrylic acid, 5 parts of potassium persulfate and 100 parts of ethanol, stir to form a uniform solution, pass nitrogen to remove the oxygen in the system, place Initiate the polymerization reaction in a water bath at 60°C; react for 15 hours, and freeze-dry the reaction product to obtain monodisperse polystyrene-methacrylic acid latex particles with a particle size of 240 nm;

[0061] Step 2: ultrasonically disperse monodisperse polystyrene-methacrylic acid latex particles with a particle size of 240 nm in ethanol to form an emulsion with a mass fraction of 15 wt %;

[0062] Step 3: ultrasonically dispersing the carbon nanotubes in ethanol to form a dispersion with a mass fraction of 2 wt %;

[0063] Step 4: Mix the monodisperse polystyrene-methacrylic acid emulsion and the carbon nanotube dispersion evenly at a volume ratio of 1:2, drop-coat it on the white filter membrane, and dry it in an oven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap