A Lamb wave contact flaw detection method for 2××× aluminum alloy sheet

A technology for aluminum alloys and thin plates, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and instruments. and other issues to achieve the effect of meeting the quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

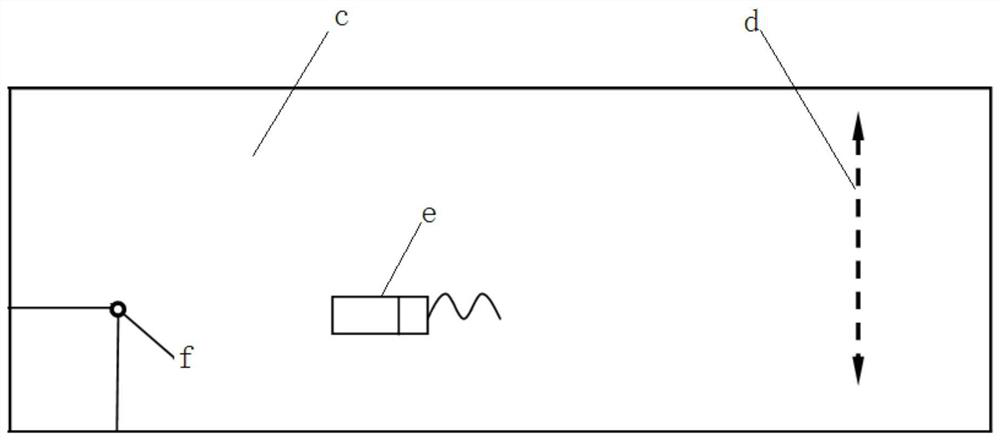

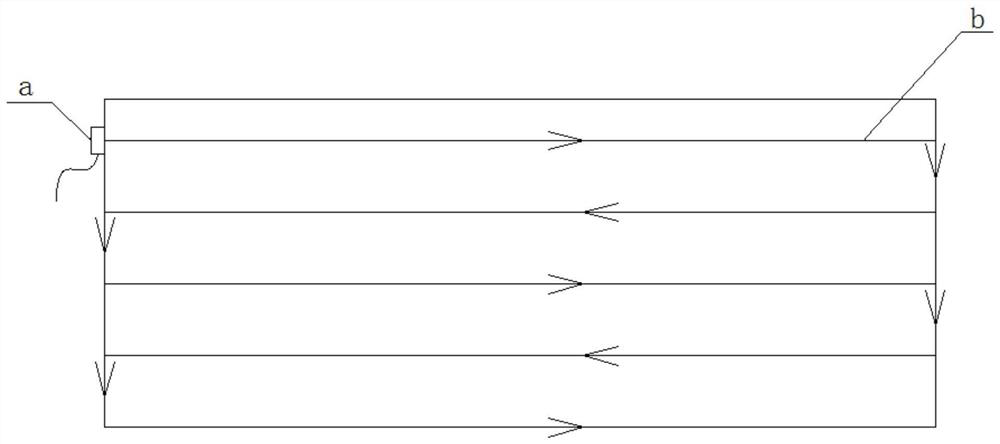

[0027] Specific implementation mode one: combine figure 1 and figure 2 To illustrate this embodiment, the Lamb wave contact flaw detection method for 2××× series aluminum alloy thin plates in this embodiment is carried out according to the following steps:

[0028] 1. Probe selection:

[0029] Select two variable-angle ultrasonic probes, marked as probe No. 1 and probe No. 2;

[0030] 2. Make a comparison test block:

[0031] Select the 2××× alloy plate with a thickness of 3.0-4.0mm as the base material, and cut it into a sample with a length of 600-610mm and a width of 150-160mm. The longer side of the sample is perpendicular to the rolling direction. And after the shearing process, the shear surface of the sample is consistent with the flatness of the surface of the plate; the center of the circle is 50mm from the shorter side and 50mm from the longer side on the sample, and an artificial through hole with a diameter of 1mm is processed to obtain a comparison test block...

specific Embodiment approach 2

[0045]Embodiment 2: This embodiment differs from Embodiment 1 in that: the range of the angle of No. 1 probe in step 1 is 0° to 60°, the size of the piezoelectric chip is 10x8 mm, and the frequency of the piezoelectric chip is 5 MHz. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0046] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the range of the angle of No. 2 probe described in step 1 is 0-60°, the size of the piezoelectric chip is 5x13mm, and the frequency of the piezoelectric chip is 4MHz. . Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com