Weed shading diagnosis and troubleshooting method for distributed photovoltaic power plants

A distributed photovoltaic and troubleshooting technology, applied in data processing applications, instruments, calculations, etc., can solve problems such as failure diagnosis and location, and achieve low economic input costs, easy implementation and operation, and obvious economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

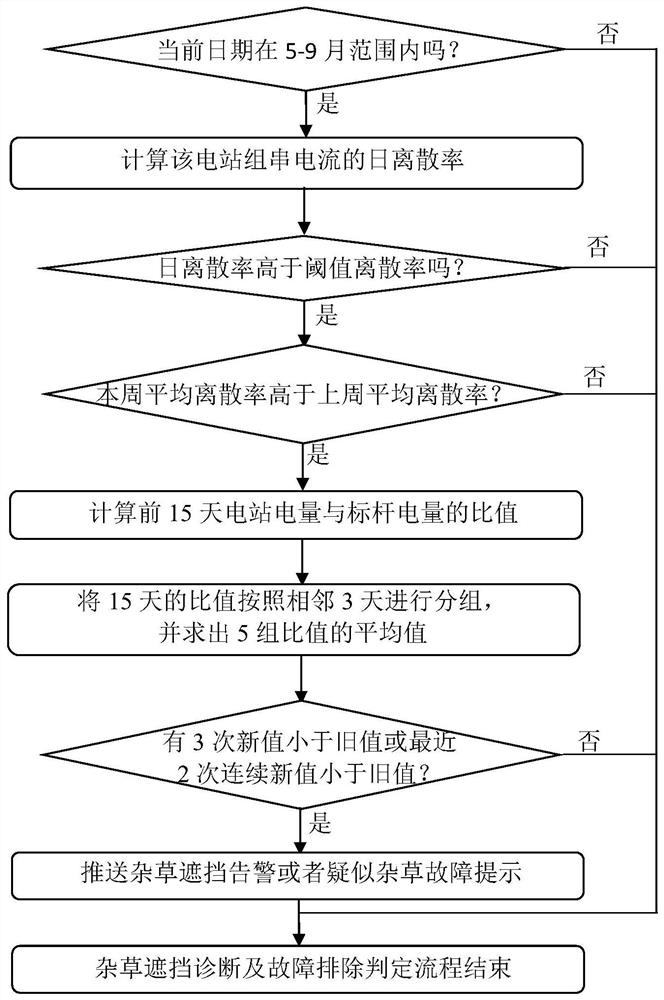

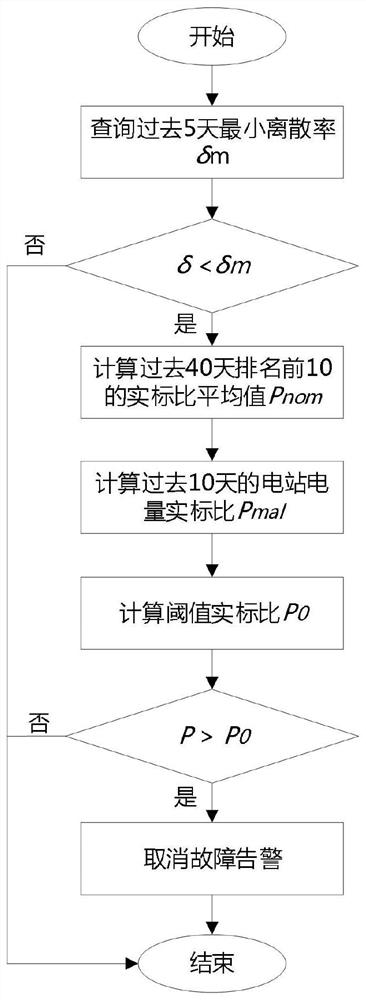

[0042] Now with reference to the accompanying drawings, the embodiments of the present invention will be described in detail. The embodiment of the present invention is divided into four major steps of weed occlusion diagnosis triggering, weed occlusion determination, weed occlusion alarm push, and weed occlusion fault troubleshooting and determination, wherein the first three steps are the process of weed occlusion fault diagnosis. It should be noted that all data in the four steps need to exclude data when faults such as external network alarms, string disconnection, and power plant equipment alarms occur. In this embodiment, a photovoltaic power station located in Jinan City, Shandong Province is taken as an example, so the diagnosis of weed shading faults is only performed during the five months from May to September.

[0043] Such as figure 1 Shown is a logic flow diagram of the present invention. The weed shading diagnosis and troubleshooting determination method of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com